Embossing in the Printing Industry: A Touch of Elegance and Sophistication

Embossing is a popular technique in the printing industry that enhances the visual and tactile appeal of printed materials. This process creates a raised or recessed impression on paper or other substrates, adding depth, texture, and an element of sophistication to various printed products.

What is Embossing?

Embossing is a finishing process that involves pressing a substrate between two dies—a raised and a recessed die—using heat and pressure to create a three-dimensional design. The result is an elegant and professional look that enhances the aesthetics of printed materials. The opposite of embossing is debossing, which creates a sunken effect rather than a raised one.

The Process of Embossing in the Printing Industry

Hot stamping typically involves the following steps:

01

Preparing the Die

A die, often made of brass, copper, or steel, is engraved with the design or text to be imprinted. The die is heated to a specific temperature, which is crucial for transferring the foil onto the material effectively.

02

Applying the Foil

A thin layer of metallic or pigmented foil is placed between the die and the substrate. The foil comes in a range of colors and finishes, from gold, silver, and holographic to matte and gloss tones.

03

Pressing and Heating

The die, which is heated to around 90°C to 200°C (194°F to 392°F), is pressed onto the foil and substrate under significant pressure. The heat activates the adhesive properties of the foil, causing it to bond with the substrate and transfer the design.

04

Cooling and Finishing

Once the foil has been transferred, the die is removed, and the printed material is allowed to cool. Afterward, excess foil is removed, and the product is inspected for quality before proceeding to the next stage in the production process.

Applications of Embossing

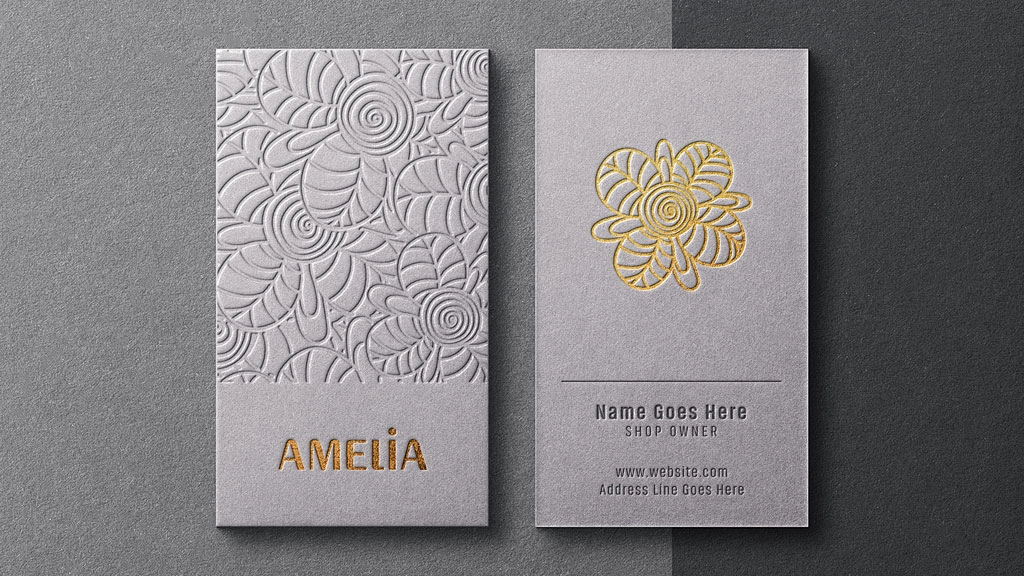

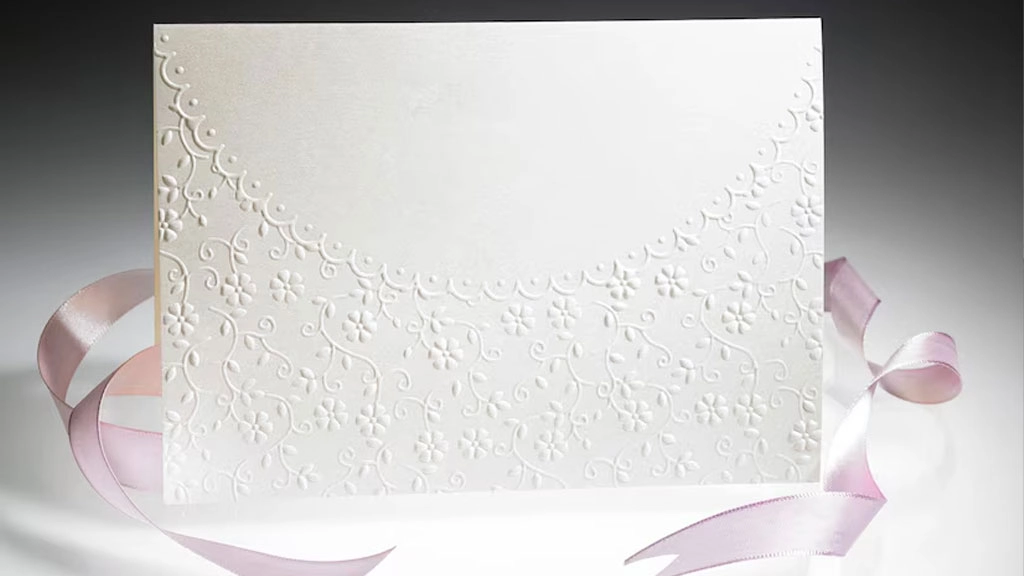

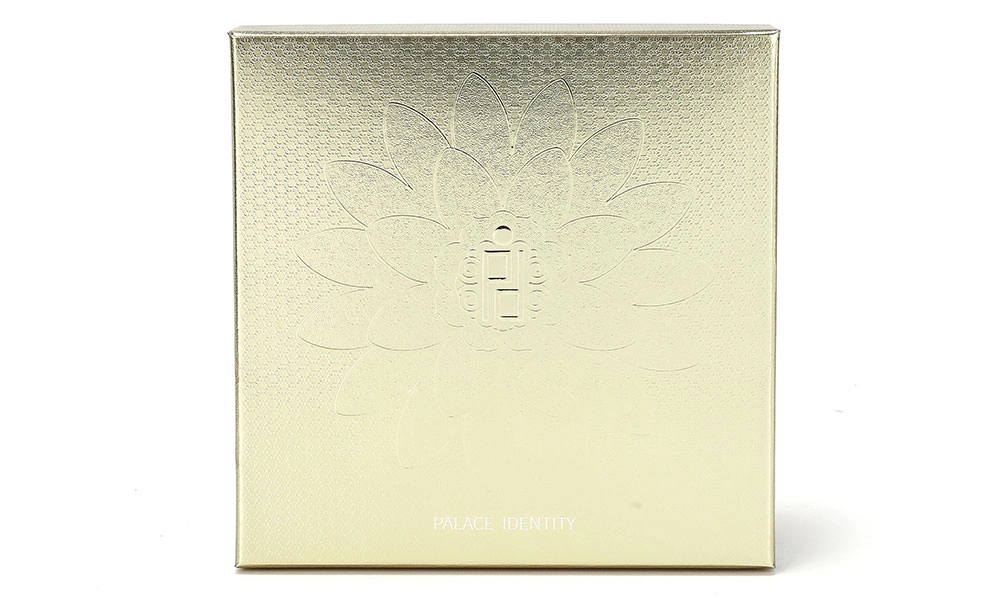

Embossing is widely used across various industries to elevate the perceived value of printed materials.

Some common applications include

Benefits of Embossing

Conclusion

Embossing remains a key technique in the printing industry, offering an elegant and high-end finish to various printed products. Whether used for business branding, packaging, or stationery, embossing enhances both the look and feel of materials, making them more engaging and impactful. With advancements in technology, the scope of embossing continues to expand, ensuring its relevance in the evolving world of print design.

Frequently Asked Questions

Everything You Need to Know About Our Printing and Packaging Services!

Rigid Magetic Boxes

Can I order a sample of my packaging box?

Yes, we strongly recommend that you do so, we provide a variety of sample types to meet different usage situations and help you guarantee the best results!

Rigid Drawer Box

Can you provide me with a die-cutting line template?

We will provide a die-cutting line template after you place an order for samples or products.

OEM Services

What is OEM packaging, and how can Winpack Printing help?

OEM (Original Equipment Manufacturer) packaging refers to custom-designed packaging solutions tailored to a brand’s specifications. At Winpack Printing, we provide end-to-end OEM services, including design, proofing, printing, and production, to help you create high-quality, market-ready packaging that aligns with your brand identity.

About Printing Craftsmanship

What factors should I consider when choosing a printing technique?

Material: Some methods work better on specific surfaces (e.g., screen printing for fabric, offset for paper).

Budget: Offset is cost-effective for large runs, while digital printing is better for short runs.

Aesthetic & Finish: If you need metallic effects, choose hot stamping; for texture, consider embossing.

Durability: UV printing and screen printing offer long-lasting prints resistant to fading.

About Us

How to start the mass production?

Once received the 30% deposite, we will arrange the mass prouction.The balance need to be paid before delivery.

Get Custom Packaging Today

Connect with our experts to find the OEM printing and packaging solution that best suits your needs. Find out how Winpack Printing meets your brand's unique requirements.

Get in touch

© 2025 WINPACK PRINTING. All rights reserved

Wenhua Printing packaging

winpackprinting

Winpack Printing