Hot Stamping in the Printing Industry: A Modern Touch of Elegance

Hot stamping, a versatile and high-impact printing technique, has become a popular choice in the printing industry for its ability to create stunning, high-quality finishes. This process, which involves applying metallic or pigmented foil to a substrate under heat and pressure, offers unique aesthetic qualities that make products stand out. Used on a variety of materials, including paper, plastic, and fabric, hot stamping is especially prevalent in the production of luxury packaging, labels, business cards, and high-end promotional materials.

What is Hot Stamping?

Hot stamping is a specialized printing technique that transfers metallic or pigmented foil to a surface using heat and pressure. Unlike traditional printing methods, which involve applying ink, hot stamping uses a pre-formed foil to imprint the design onto the material. The process combines a heated die, foil material, and the substrate being printed on to create an impression that is both durable and visually striking.

The Process of Hot Stamping in the Printing Industry

Hot stamping typically involves the following steps:

01

Preparing the Die

A die, often made of brass, copper, or steel, is engraved with the design or text to be imprinted. The die is heated to a specific temperature, which is crucial for transferring the foil onto the material effectively.

02

Applying the Foil

A thin layer of metallic or pigmented foil is placed between the die and the substrate. The foil comes in a range of colors and finishes, from gold, silver, and holographic to matte and gloss tones.

03

Pressing and Heating

The die, which is heated to around 90°C to 200°C (194°F to 392°F), is pressed onto the foil and substrate under significant pressure. The heat activates the adhesive properties of the foil, causing it to bond with the substrate and transfer the design.

04

Cooling and Finishing

Once the foil has been transferred, the die is removed, and the printed material is allowed to cool. Afterward, excess foil is removed, and the product is inspected for quality before proceeding to the next stage in the production process.

Applications of Hot Stamping in the Printing Industry

Hot stamping is used in many areas of the printing industry, particularly where a high-quality, luxurious, or eye-catching finish is needed.

Here are some of the key applications:

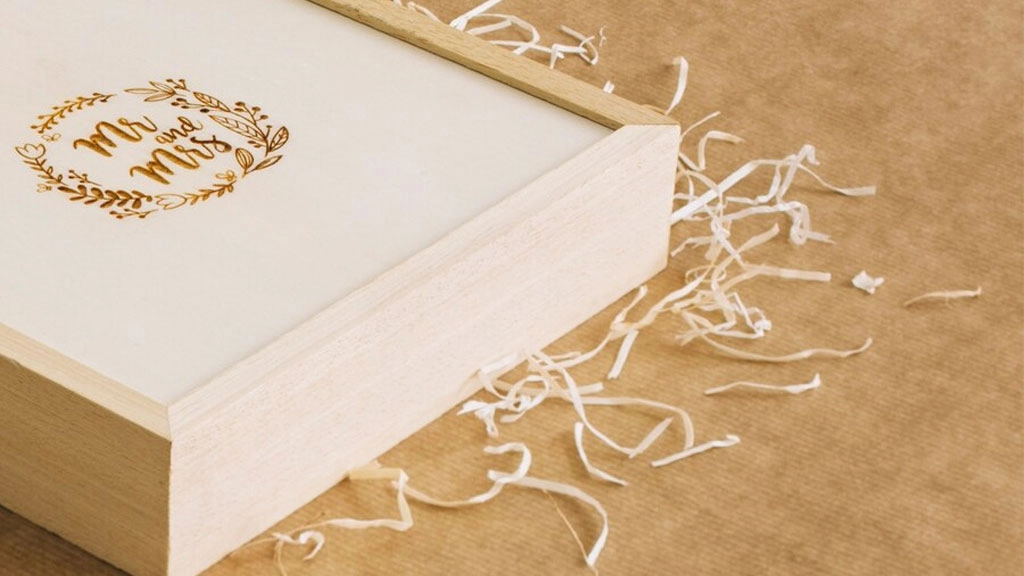

Luxury Packaging

Business Cards

Event Invitations and Greeting Cards

Labels and Stickers

Gift Wrap and Stationery

Benefits of Hot Stamping

Challenges and Considerations

While hot stamping offers many benefits, it also comes with a few challenges. For one, the initial cost of creating the die can be high, especially for intricate or custom designs. Additionally, the process requires precise control over temperature, pressure, and timing, as variations can lead to imperfect results such as foil transfer failures or inconsistent impressions.

Hot stamping is also not ideal for high-volume jobs where the cost of the dies and set-up time may outweigh the benefits, especially in comparison to traditional offset or digital printing methods.

Conclusion

Hot stamping has firmly established itself as a standout technique in the printing industry, particularly for those seeking premium finishes and designs that make a statement. Whether for packaging, business cards, or luxury promotional materials, hot stamping offers an aesthetic quality that is hard to replicate. With its ability to add a sense of elegance, sophistication, and durability to printed products, it’s no wonder that businesses continue to embrace this timeless technique to enhance their brand and make a lasting impression on their customers.

Frequently Asked Questions

Everything You Need to Know About Our Printing and Packaging Services!

About Printing Craftsmanship

What are the advantages of embossing?

Enhances the visual and tactile appeal of printed products.

Creates a premium and professional look.

Improves brand recognition with distinct textures.

Increases durability as the embossed design remains intact over time.

What is the best printing technique for business cards?

It depends on the desired effect:

Hot stamping for a premium metallic finish.

Embossing for a raised, tactile design.

Spot UV for glossy highlights on specific areas.

Digital printing for quick, affordable, and full-color printing.

What are eco-friendly printing options?

Vegetable-based inks instead of petroleum-based inks.

Recycled paper or sustainably sourced materials.

Water-based coatings instead of harmful chemical coatings.

Digital printing to reduce waste and energy consumption.

What are the different types of printing techniques?

There are various printing techniques used for different purposes, including:

Offset Printing – Ideal for high-volume commercial printing, offering sharp and high-quality images.

Digital Printing – Suitable for short-run printing with fast turnaround times.

Screen Printing – Used for printing on textiles, plastics, and other materials with thick ink layers.

Hot Stamping – Adds metallic or pigmented foil using heat and pressure for a luxurious look.

Embossing & Debossing – Creates raised or recessed designs for a textured effect.

UV Printing – Uses ultraviolet light to instantly dry ink, offering vibrant colors and enhanced durability.

What is screen printing used for?

Screen printing is ideal for printing on a variety of surfaces, including:

Fabric (t-shirts, tote bags)

Plastic (bottles, packaging)

Paper (posters, packaging)

Metal and glass (signs, promotional products)

Get Custom Packaging Today

Connect with our experts to find the OEM printing and packaging solution that best suits your needs. Find out how Winpack Printing meets your brand's unique requirements.

Get in touch

© 2025 WINPACK PRINTING. All rights reserved

Wenhua Printing packaging

winpackprinting

Winpack Printing