Silkscreen Printing: A Versatile and Durable Printing Method

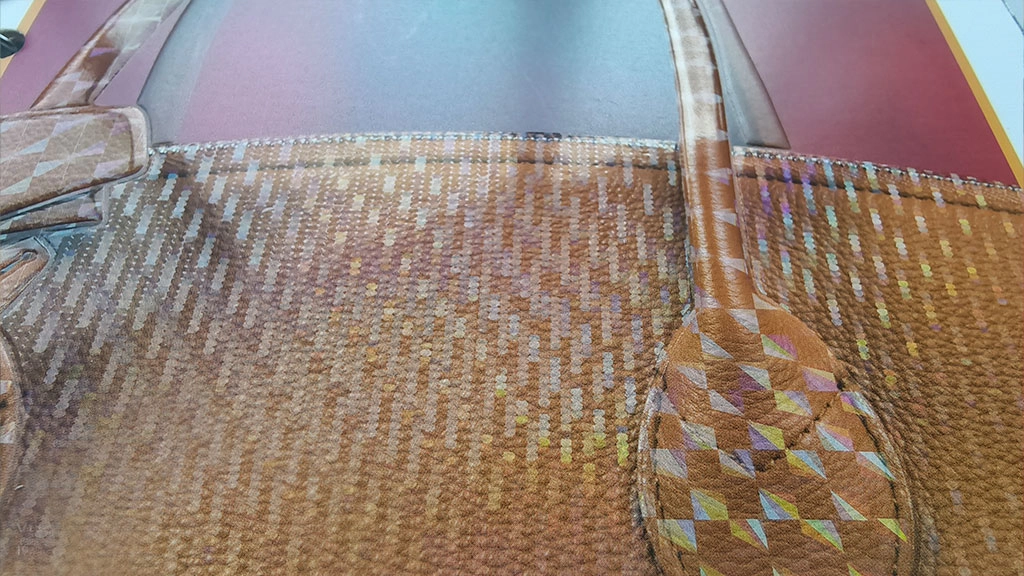

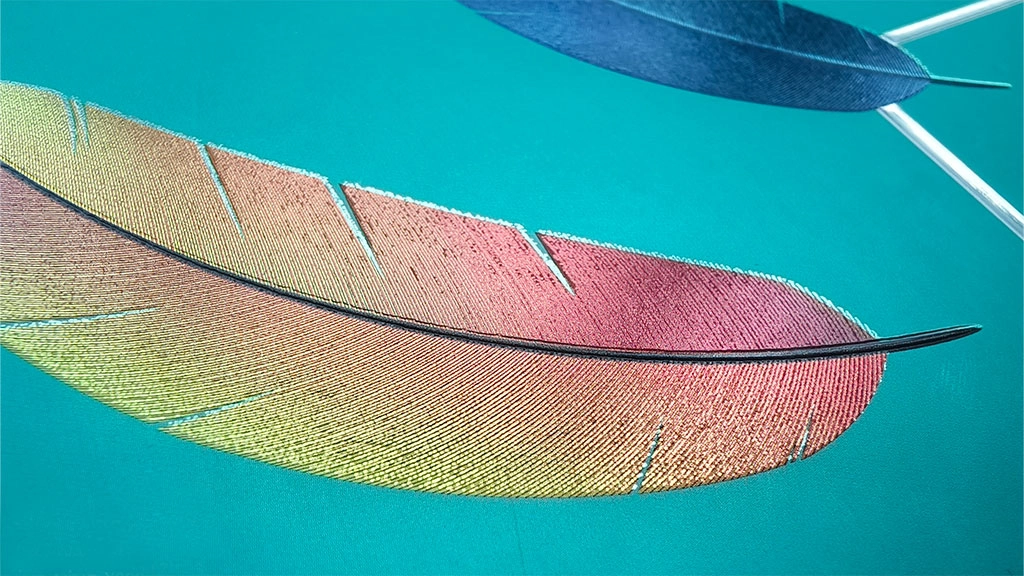

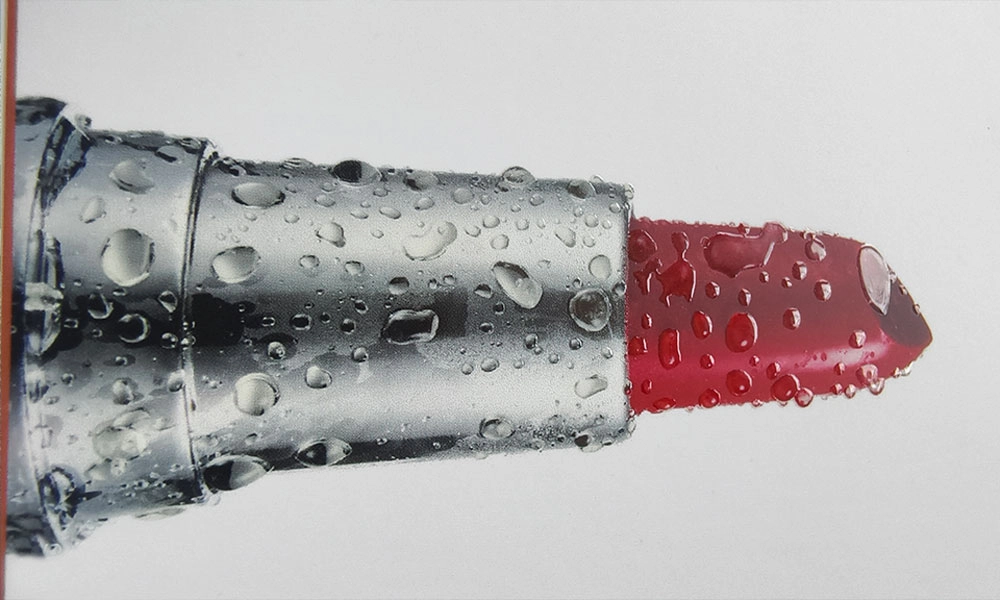

Silkscreen printing, also known as screen printing, is a widely used printing technique that involves transferring ink through a mesh screen onto a substrate. This method is renowned for its versatility, durability, and vibrant color output, making it a popular choice for various applications across industries.

What is Silkscreen Printing?

Silkscreen printing is a printing process that uses a fine mesh screen, a stencil, and ink to create designs on different surfaces. The technique involves forcing ink through the open areas of the stencil using a squeegee, ensuring precise image transfer onto the material. Traditionally, silk was used for the mesh, which is why the process is called silkscreen printing, although modern screens are typically made from synthetic materials like polyester.

The Silkscreen Printing Process

The process of silkscreen printing involves several key steps:

01

Design Preparation

The desired design is created digitally and then transferred onto a stencil.

02

Screen Preparation

A mesh screen is coated with a light-sensitive emulsion and exposed to the design using UV light, hardening the exposed areas while keeping the design portion washout.

03

Ink Application

Ink is applied to the top of the screen, and a squeegee is used to push the ink through the stencil openings onto the substrate.

04

Curing and Drying

The printed material is dried and cured using heat to ensure the ink adheres properly and lasts longer.

05

Final Inspection

The print is checked for quality, and any excess ink or imperfections are addressed.

Applications of Silkscreen Printing

Silkscreen printing is widely used in various industries due to its ability to print on multiple materials, including fabric, paper, plastic, metal, and wood.

Common applications include

Advantages of Silkscreen Printing

Limitations of Silkscreen Printing

While silkscreen printing offers numerous benefits, it also has some drawbacks:

Conclusion

Silkscreen printing remains a preferred method for producing high-quality, durable prints across various industries. Its ability to deliver bold and long-lasting designs on multiple surfaces makes it a staple in the world of printing.

While newer digital printing technologies continue to evolve, silkscreen printing maintains its relevance due to its unmatched vibrancy, resilience, and cost-effectiveness for large-scale production.

Frequently Asked Questions

Everything You Need to Know About Our Printing and Packaging Services!

About Printing Craftsmanship

What is the difference between offset and digital printing?

Offset Printing: Best for large-volume production, offering high-quality prints at a lower cost per unit.

Digital Printing: Suitable for short runs, allowing quick setup, customization, and fast printing.

How do I ensure high-quality printing results?

Use high-resolution images and vector files.

Choose the appropriate paper or substrate.

Work with a professional printing service.

Consider color matching systems like Pantone for consistent results.

Request print samples before full production.

What are the advantages of embossing?

Enhances the visual and tactile appeal of printed products.

Creates a premium and professional look.

Improves brand recognition with distinct textures.

Increases durability as the embossed design remains intact over time.

What is embossing, and how is it different from debossing?

Embossing is a technique that creates a raised impression on a material, while debossing presses the design inward, creating a recessed effect. Both techniques add texture and sophistication to printed materials.

What factors should I consider when choosing a printing technique?

Material: Some methods work better on specific surfaces (e.g., screen printing for fabric, offset for paper).

Budget: Offset is cost-effective for large runs, while digital printing is better for short runs.

Aesthetic & Finish: If you need metallic effects, choose hot stamping; for texture, consider embossing.

Durability: UV printing and screen printing offer long-lasting prints resistant to fading.

Get Custom Packaging Today

Connect with our experts to find the OEM printing and packaging solution that best suits your needs. Find out how Winpack Printing meets your brand's unique requirements.

Get in touch

© 2025 WINPACK PRINTING. All rights reserved

Wenhua Printing packaging

winpackprinting

Winpack Printing