Understanding Screen Printing: A Comprehensive Guide

Welcome to the vibrant world of screen printing, where traditional artistry meets modern technology to create everything from the eye-catching graphics on your favourite T-shirt to the intricate designs adorning luxury packaging. Did you know that over 30 per cent of all printed fabrics and high-end packaging would not exist without screen printing? This method is not only popular, it is also a necessity for contemporary manufacturing and design.

This guide will give you an overview of the history of screen printing, from its origins in ancient China to its current status as the backbone of today's creative industries. You will learn the step-by-step process behind those vibrant, long-lasting prints and discover the various industrial applications of this technique, which remains the gold standard for precision and durability in the work of companies and artists alike. So let's jump in and explore how screen printing continues to be a pillar of creativity and quality in the contemporary world.

- So, What Is Screen Printing?

- Screen Printing Process: A Step-By-Step Guide

- 1. Design creation

- 2. Screen preparation

- 3. Stencil creation

- 4. Ink application

- 5. Curing the ink

- Uses Of Screen Printing: Flexibility In Industry

- 1.Clothing And Textiles: The Fashion Leader

- 2.Non-Garment Items: Art To Electronics

- 3.Product Packaging And Labels: Improving Brand Identity

- 4. Exceptional Technical Uses: Accuracy In Technology

- 5. Making Creative Visions a Reality

- The Benefits Of Screen Printing: Strength, Flexibility, And Productivity

- 1.Durability And Quality: Lasting Prints

- 2.Fit for Long Runs: Economical Mass Production

- 3.Flexibility And Versatility In Various Materials: Accuracy And Adaptability

- Typical Problems And Solutions In Screen Printing: Troubleshooting Guide

- 1.Ink Bleeding: Fuzzy Edge Prevention

- 2.Image Sharpening: Picture Perfect

- 3.Moiré patterns: Removing Unwanted Patterns

- The Future of Screen Printing: New Ideas And Trends

- 1.Digital Miracles And Automation

- 2.Eco-friendly Innovations

- 3.New Materials And Applications

So, What Is Screen Printing?

Silk screening, also known as screen printing, is an ancient process characterised by the transfer of ink onto various materials using a stenciled mesh screen. Developed in ancient China, this technique has become a manufacturing giant with a reputation for creating colourful, durable designs for a wide range of applications, including textiles, metal, paper and glass.

The screens were originally made of silk, hence the term 'silk screening'. While most screens today are made of synthetic materials such as polyester, the historical name is still used, particularly in artistic circles. The term 'serigraphy', commonly used in the art community, highlights the importance of this technique in producing fine art prints and the expertise and ingenuity required to achieve its characteristic high-quality results.

As you explore the world of screen printing, you will discover an intriguing intersection of science and art. Also known as silk screening or serigraphy, this versatile process continues to offer endless opportunities for creativity and innovation in the commercial and artistic worlds.

Screen Printing Process: A Step-By-Step Guide

Understanding how the screen printing process works will make you appreciate the artistry behind every printed product. Whether you are creating your own products or are simply interested in how your favourite screen-printed products are made, this guide will help you understand the key steps involved in screen printing.

1. Design creation

Every screen printing project begins with a design. This can be digital or hand-drawn. This design is then transferred onto transparent acetate film, which is important for forming the stencil that determines where the ink is applied to the substrate.

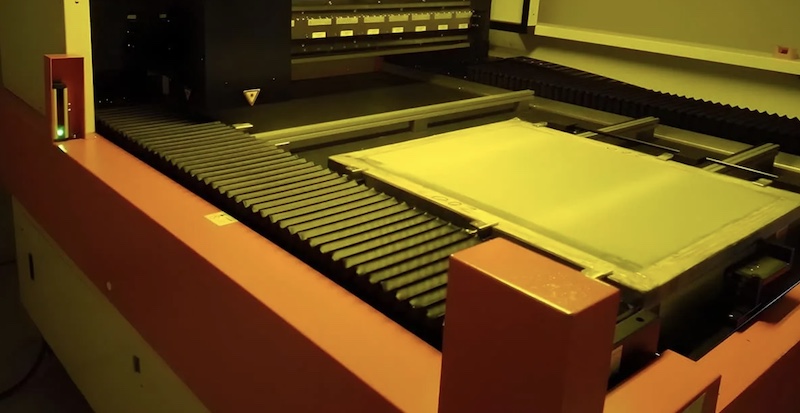

2. Screen preparation

Screen preparation is at the core of screen printing. This is a fine mesh, traditionally made of silk but nowadays often made of polyester, which is stretched over a frame. A light-sensitive emulsion is then applied to the mesh. This solidifies when exposed to light, leaving the parts of the design that have been covered transparent. The accuracy of the screen preparation greatly influences the detail and sharpness of the final print.

3. Stencil creation

Now that the screen is prepared, it is time to make the stencil. The design is placed on acetate film, which is then placed on the screen. The two are then exposed to light. The emulsion solidifies due to the light, except where the design prevents this. This forms a stencil through which the ink can only flow where desired.

4. Ink application

Once the stencil has been placed, the screen is positioned on top of the desired substrate, whether it be fabric, paper or another material. The ink is placed on top of the screen and is then pushed evenly across it with a squeegee. The design is transferred to the substrate when the ink flows through the mesh in the stencil areas.

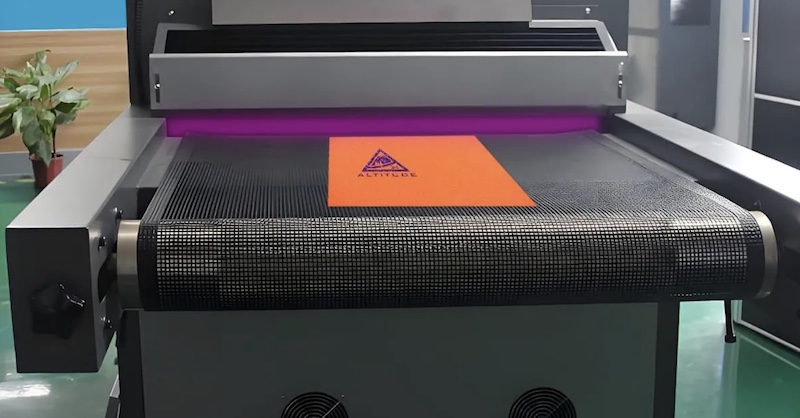

5. Curing the ink

The final step is to dry the ink so that it sticks and lasts a long time. This is usually done using a heat tunnel or heat press, which hardens the ink, making it waterproof, colourless and durable.

Uses Of Screen Printing: Flexibility In Industry

Screen printing is a flexible process with applications in a broad range of industries, from everyday objects to specialised products. Understanding the various applications of screen printing can help you find new ways to enhance your projects.

1.Clothing And Textiles: The Fashion Leader

Perhaps the most well-known industry for screen printing is the textile industry, where it is used to add colourful graphics to T-shirts, hoodies and hats. Screen-printed designs are also a popular choice for fashion and functional clothing due to their durability; they can be washed and worn day after day, unlike many other printing techniques. In addition to clothing, screen printing can be used to produce banners, flags and bags, offering opportunities for branding and personal expression.

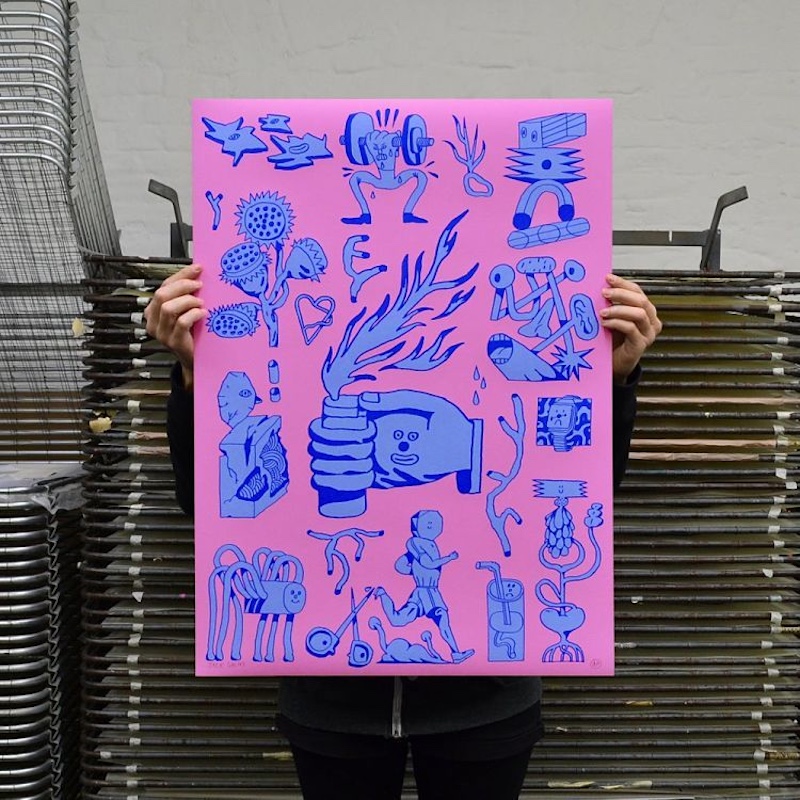

2.Non-Garment Items: Art To Electronics

Screen printing is not limited to textiles. It is also used to create other non-garment products, such as bold concert posters, complex artwork and detailed prints on electronic devices and medical appliances. This technique ensures that every item has readable displays and controls, which are essential for technical use and regulatory compliance.

3.Product Packaging And Labels: Improving Brand Identity

Screen printing also plays a key role in improving product packaging and labels, which are vital for brand recognition and customer interaction. This application is especially useful for:

Paper bags: Paper bags are widely used in retail. Kraft paper bags or coloured paper bags can be screen printed to make them more durable and attractive, thereby increasing brand recognition.

Luxury rigid boxes: When a product is high-end, screen printing on cloth, leather or velvet enhances the unboxing experience, making it more memorable.

Hardcover book covers: Screen printing on book covers allows for unique and artistic touches, making each volume different and creating a distinctive appearance.

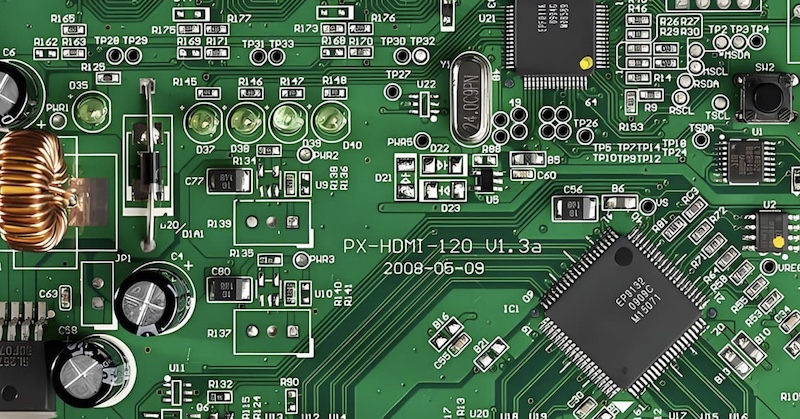

4. Exceptional Technical Uses: Accuracy In Technology

Screen printing is also very useful in the electronics and technology industries, as it is the most accurate method of applying conductive inks to circuit boards and other components. This accuracy is essential for developing the intricate circuits required to power devices, from simple to sophisticated.

5. Making Creative Visions a Reality

These applications demonstrate how screen printing can be adapted to suit the various needs of different industries and meet the current requirements for beauty and functionality. Screen printing is a reliable and flexible solution for bringing your creative ideas to life, whether you are designing wearable art, improving product packaging or creating precision parts for technology.

The Benefits Of Screen Printing: Strength, Flexibility, And Productivity

Screen printing is unique in the printing industry thanks to its high level of durability, flexibility and affordability. This section outlines the key advantages of screen printing and is supported by comparative analysis and quantitative data where available.

1.Durability And Quality: Lasting Prints

Screen printing is renowned for its durability, ensuring that prints remain bright and vibrant over time. Screen-printed designs have been proven to endure hundreds of wash cycles without fading and to last much longer than digitally printed garments, which tend to wear out after only 50 cycles. This is due to the heavy application of ink, which keeps colours sharp and clear and details crisp. This makes screen printing the best option for outdoor gear and apparel that requires long-lasting quality.

2.Fit for Long Runs: Economical Mass Production

Screen printing is highly efficient and cost-effective for large-scale production. Although the initial setup may be time-consuming, the process becomes highly cost-effective when dealing with large orders. With prepared screens, hundreds or even thousands of items can be printed in a short period of time at a much lower unit cost than with digital printing. For example, screen printing can save up to 70% on production costs for orders of more than 500 items, and the quality of all the items will be the same.

3.Flexibility And Versatility In Various Materials: Accuracy And Adaptability

Another major strength of screen printing is its ability to print on a wide range of materials. Whether you are working with fabric, wood, metal, glass or plastic, screen printing provides great adhesion and colour control. Comparative analyses have shown that the colour fidelity of screen-printed inks on materials such as glass and metal is up to 30 per cent higher than that of inks printed using digital techniques. This makes screen printing the preferred choice for many industrial applications that require precision and permanence.

Typical Problems And Solutions In Screen Printing: Troubleshooting Guide

Even experienced experts may encounter a number of problems when screen printing. To help you achieve high-quality results consistently, we have compiled a list of common issues and solutions. This practical guide will help improve your screen printing process and ensure your projects meet the highest standards.

1.Ink Bleeding: Fuzzy Edge Prevention

Difficulty: Ink spreads outside the design lines, creating blurred or fuzzy edges.

Solution: Ensure that the mesh count is appropriate for the ink viscosity and level of detail in your design. Using a heavier stencil will help to hold the ink and reducing the squeegee pressure will give you better control over the ink flow so that it does not leak outside the design area.

2.Image Sharpening: Picture Perfect

Problem: Photos are not sharp or clear, particularly when dealing with finer details.

Solution: Ensure that your screens are well tensioned, as loose screens may distort images. Make sure that the mesh count matches the level of detail required by your design. Additionally, set the exposure times correctly during the stencil creation process to prevent under- or over-exposure, both of which may result in a blurred final print.

3.Moiré patterns: Removing Unwanted Patterns

Problem: Moiré (undesired wavy patterns) is caused by misaligned patterns of screen dots.

Solution: Rotate the halftone screens at angles of 22.5 or 45 degrees with respect to the mesh lines to reduce moiré patterns. Test different mesh numbers and dot shapes to determine the most effective combination. Exact registration and high-quality screens are also essential in preventing this problem.

The Future of Screen Printing: New Ideas And Trends

Screen printing is set to evolve significantly in the future due to new trends and improvements. This evolution combines traditional methods with the latest technological solutions in response to market shifts and an increased focus on climate sustainability. This is what we can expect as screen printing continues to advance.

1.Digital Miracles And Automation

Trend: The industry is being transformed by the incorporation of digital technologies into traditional screen printing processes. Progress in digitisation is making print runs more accurate and flexible, and enabling customisation that would previously have been difficult or expensive.

Future impact: We can expect to see an increase in automated digital screen printers with quicker turnaround times and lower labour costs. These technologies will also facilitate the production of more complex and customised designs on a large scale, in response to the growing consumer demand for customised products.

2.Eco-friendly Innovations

Trend: The issue of sustainability is becoming increasingly important in screen printing, due to environmental restrictions and a shift in consumer tastes towards more eco-friendly products.

Future effect: The development of eco-friendly inks, such as soy-based or other natural inks, will reduce the environmental footprint of screen printing. These inks are also safer as they reduce toxic emissions in the workplace. The industry is also investigating more efficient cleaning and recycling methods to further reduce waste.

3.New Materials And Applications

Trend: The development of ink and screen technologies is enabling screen printing to be applied to new and unconventional substrates, thus expanding its range of applications.

Future impact: The future of screen printing is expected to see expansion into industrial usage, particularly in the automotive and electronics industries, where durability and precision are paramount. Printed electronics, such as sensors and interfaces, may also be produced through innovations that are built directly into other devices.

About Printing Craftsmanship

What is embossing, and how is it different from debossing?

Embossing is a technique that creates a raised impression on a material, while debossing presses the design inward, creating a recessed effect. Both techniques add texture and sophistication to printed materials.

Rigid Magetic Boxes

Can I get a sample before placing an official order?

Yes, we provide samples to our customers. Please contact our sales team to inquire about sample availability and pricing.

OEM Services

Do you offer eco-friendly and sustainable packaging options?

Yes! We provide environmentally friendly packaging solutions, including recyclable, biodegradable, and FSC-certified paper materials. Let us know if you’re looking for sustainable options.

What is the minimum order quantity (MOQ) for OEM orders?

Our MOQ varies depending on the type of packaging and material used. We offer flexible MOQ options to accommodate both small businesses and large-scale manufacturers. Contact us for a tailored quote based on your needs.

About Us

What kind of format is available for printing?

CDR, AI, PS , PSD. high resolution JPG (please Convert text to curves. If not, some words will be missing.)

Start Your Packaging Journey Today

Discover Our Curated Collection of Bespoke Packaging Cases & Tailored System Solutions

© 2025 WINPACK PRINTING. All rights reserved

Wenhua Printing packaging

winpackprinting

Winpack Printing