What is Water-based Ink?

When you need a green alternative to traditional printing, water-based ink is a more environmentally friendly option. Unlike solvent-based solutions, it significantly reduces dangerous emissions during production.

This type of ink is particularly suitable for use in the packaging and textile industries, producing a bright, smooth finish. Water-based ink dries quickly, making it more productive while still achieving high-quality results.

Using water-based solutions allows you to fulfil all of your artistic and environmental requirements while keeping up the creative tradition and saving the planet.

- What Is Water-based Ink?

- 1.Define Water-based Ink

- 2. Water-based Ink Composition

- 2. The Difference Between It And Other Inks

- Benefits of Water-Based Ink

- 1.Environmental Advantages

- 2.Health And Safety Benefits

- 3.Economic Considerations

- Uses of Water-based Ink

- 1.Uses In The Printing Industry

- 2.Creative And Artistic Uses

- 3.Packaging And Labelling

- 4.Textile And Fabric Printing

- Curing Water-based Ink

- In conclusion

What Is Water-based Ink?

Water-based ink is a more sustainable printing method that uses water as the solvent. This type of ink is a sustainable alternative to traditional solvent-based inks, making it the ideal choice for modern, environmentally conscious customers. It is an alternative that makes the printing industry more responsible.

It favours businesses that are trying to reduce their environmental impact. The ink is water-based and produces rich, colourful prints with a smooth finish. This contributes to its popularity among screen printers, especially for printing on clothing.

The soft feel is a significant factor in the comfort of wearables and contributes to the perceived value of the end product. Water-based ink is becoming more popular as more consumers insist on environmentally friendly production processes. This movement is part of a larger trend towards more environmentally friendly production processes.

1.Define Water-based Ink

Water-based ink is environmentally friendly and safe to use in various applications because it uses water as the carrier rather than chemical solvents. It is widely used in screen printing to produce bright, high-quality prints with fewer adverse effects during production and usage.

This makes it particularly well-suited to use on fabrics such as T-shirts, where comfort is the main consideration. The printing industry is growing in popularity due to the increasing focus on sustainability. Both businesses and consumers are demanding products that can help them to become more environmentally friendly.

2. Water-based Ink Composition

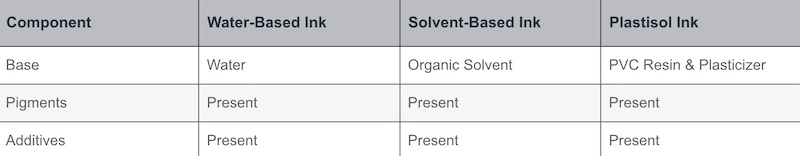

Water-based inks contain a number of ingredients, each of which plays a role in achieving the correct print quality and performance. The major ingredients are pigments, water and other additives. Water-based pigments provide high-quality, bright colours, ensuring that your prints are lively and eye-catching.

In this case, the solvent is water, meaning the ink can be easily applied to any surface. Additives are added to achieve properties such as drying time and adhesion. Adding water-based ink to ink at a proportion of 1.5 percent by weight enhances its properties.

This makes the ink more versatile for use in various applications within the range of print production. The composition of water-based ink is compared with that of other inks in the table below:

2. The Difference Between It And Other Inks

There are certain inherent differences between water-based inks and solvent-based and plastisol inks, particularly with regard to environmental issues. Solvent-based inks require chemical solvents that are harmful to the environment and human health. Water-based inks utilise water, eliminating these concerns.

Plastisol inks are based on PVC resins and therefore require an energy-intensive curing process. Water-based inks can be cured using just a standard dryer and Warp Drive. You should be prepared to repeat the tests to ensure they are fully cured.

They are known to dry faster than their solvent-based counterparts. Water-based ink is a magical substance with dynamic characteristics that produce really vivid colours. This property makes it ideal for printing on dischargeable 100% cotton and reactive-dyed dark clothes, giving them a soft, 'my favourite tee' appearance.

It is also versatile and easy to use, allowing you to mix it with Eco-Pigments to create an unlimited number of colours.

Benefits of Water-Based Ink

Water-based inks have many advantages, such as being eco-friendly and versatile. They are an excellent choice as they produce some of the most colourful and vivid prints. Furthermore, they minimise contact with dangerous chemicals. These inks are quickly gaining popularity as the ink of choice for those who want to adopt sustainable printing habits, as they are far more environmentally friendly than conventional inks.

1.Environmental Advantages

Water-based inks are biodegradable and non-toxic, so they cause little or no toxicity to humans or the environment. Unlike solvent-based inks, which normally emit toxic chemicals into our environment, water-based inks break down, minimising waste and pollution.

They have a much smaller carbon footprint as they eliminate all petrochemical solvents from the printing process. The fashion, packaging and publishing industries thrive on sustainable print solutions. This will enable them to align their operations with the zero waste movement and greatly reduce their ecological footprint.

2.Health And Safety Benefits

Using water-based inks can facilitate a healthier workspace. They minimise exposure to toxic chemicals. Printing industry workers are less exposed to volatile organic compounds and vinyl chloride monomers, which are prevalent in other inks.

This shift towards safer options not only makes workers safer, but also meets consumer demand for healthier products. This is why most children's clothing brands use water-based inks. We would like to congratulate them on making this great choice to ensure that their products contain no other toxins and are safe for young skin.

3.Economic Considerations

From an economic perspective, water-based inks are cheaper than plastisol inks. They are water-based, so can be easily cleaned up. This eliminates the need for costly petrochemical solvents and the expense of environmentally friendly disposal.

As the global market continues to shift towards sustainable choices, companies can benefit from this consumer shift. Water-based inks are already the norm in Asia, Europe and other parts of the world. These characteristics enable businesses to meet consumer demand for sustainability and provide prints that are colourfast and abrasion-resistant for up to five years.

Water-based inks have various useful advantages. They are highly recommended for screen printing as they are easy to use and require fewer processing steps. They can produce photorealistic images and capture microscopic details, making them ideal for printing high-resolution artwork and improving the overall quality of the final product.

Furthermore, being 100% VOC-free improves the efficiency of the press, allowing for a higher press speed and increased productivity.

Uses of Water-based Ink

In the food and beverage packaging and textile industries, water-based inks are the most suitable all-purpose solution, offering environmental and functional benefits to a wide range of industries. Their flexibility allows them to be used in thousands of applications, from small-scale fine art projects to large-scale retail printing.

Water-based ink is commonly used in screen printing and most other printing applications. This ink is ideal for producing both fast and complex designs. It is particularly effective in achieving the most vivid colours. This is why it is most often used in offset printing, due to its high level of detail and colour precision.

1.Uses In The Printing Industry

Water-based ink is widely used in most printing applications, such as screen printing. This ink is ideal for quick and complex designs. It is particularly effective for achieving the most vivid and bright colours. It is most commonly used in offset printing due to its high level of detail and colour accuracy.

Another good place to see water-based inks in action is in commercial printing, where high-quality images and text are produced. There is a new trend in this industry towards green practices. This is where water-based inks come in, making a difference by significantly reducing environmental harm.

These inks are most effective when printing on light-coloured paper, such as pastels and whites. This makes them ideal for creating sharp, vivid images.

2.Creative And Artistic Uses

We are therefore thrilled to learn that water-based inks are becoming an amazing resource for artists. They are also versatile and can be used to create unique art pieces and fine art prints. These inks are marvellous for any painting or mixed media project.

They can be combined with Eco-Pigments to create thousands of unique colours. Their flexibility makes them ideal for more inventive projects, allowing you to explore your creativity and produce something truly innovative.

In screen printing, posters can be printed using water-based inks. These inks can be combined with other media to create dense, layered compositions. In fact, the history of water-based inks is long and rich, and can be traced back thousands of years. They were used by ancient civilisations such as the Egyptians and the Chinese to inscribe surfaces such as papyrus and silk.

3.Packaging And Labelling

Water-based inks are at the forefront of developing sustainable packaging solutions. They are used for personalising labels and cartons, which is important for brand identity. The inks are also a safe option for food packaging as they are non-toxic.

The ability to create unique, colourful packaging that attracts attention and fits perfectly with sustainable initiatives is key to business profitability. Water-based inks ensure that packaging is both aesthetically pleasing and sustainable.

4.Textile And Fabric Printing

Water-based inks are best used for printing on textiles and fabrics, particularly natural fibres such as cotton. These inks can be used to print on dischargeable 100% cotton and reactive-dyed dark clothing. Create comfortable, breathable designs for clothing!

Short-run, on-demand digital printing using water-based inks enables small batch production. This capability is hugely beneficial to the textile and apparel industry. This flexibility allows for a faster reaction to rapidly changing fashion trends and the ability to create garment designs on demand.

The curing process uses a standard dryer and a little Warp Drive, demonstrating its practicality in textile applications.

Curing Water-based Ink

Water-based ink is the popular choice for all printers due to its environmental qualities and smooth finishes. To ensure these prints remain as vivid and durable as on the day they were printed, they must be cured. This process involves heating the ink.

This ensures that the ink sticks properly to the fabric, giving your prints long-lasting durability. Without an extensive cure, prints can crack or fade, losing quality and beauty. In this article, we will take a closer look at the curing process, explain why it is so important, and provide you with the most practical tips to help you achieve the best results.

In conclusion

In conclusion, the future of printing lies in water-based ink. Its environmental friendliness and softness on surfaces make it ideal for textiles, graphics and more. You can invest in sustainability without sacrificing rich colours or longevity by using quality water-based ink. Additives allow for further personalisation, enabling you to create eye-catching prints.

The advantages are obvious: reduced environmental impact, a wide range of applications and high performance. It's not just a smart decision to make; it's an investment in a healthier, greener future.

Are you ready to make the switch? Contact Winpack Printing today to find out how we can support your next packaging project with our new environmentally friendly printing services. We can work together to help your business become a leader in sustainable packaging. Find out more about our range of water-based inks and experience the difference in quality and sustainability for yourself.

Rigid Magetic Boxes

Can I get a sample before placing an official order?

Yes, we provide samples to our customers. Please contact our sales team to inquire about sample availability and pricing.

About Us

Do you inspect the finished products?

Yes, each step of production and finished product will be carried out inspection

Rigid Lift-off Box

Can I print on the inside of the box?

Yes, you can print any effect you want on the inside.

Rigid Drawer Box

Can you provide me with a die-cutting line template?

We will provide a die-cutting line template after you place an order for samples or products.

About Printing Craftsmanship

What is the best printing technique for business cards?

It depends on the desired effect:

Hot stamping for a premium metallic finish.

Embossing for a raised, tactile design.

Spot UV for glossy highlights on specific areas.

Digital printing for quick, affordable, and full-color printing.

Start Your Packaging Journey Today

Discover Our Curated Collection of Bespoke Packaging Cases & Tailored System Solutions

© 2025 WINPACK PRINTING. All rights reserved

Wenhua Printing packaging

winpackprinting

Winpack Printing