What is flocking?

In the competitive world of packaging, it is important to develop a differentiated product. Enter flocking, a method that has quickly become popular due to its ability to transform ordinary packaging into an experience that can be felt as well as seen. But what exactly is flocking, and why has it become such a popular solution for both high-end and everyday brands?

This detailed manual delves into the flocking process and its many advantages, as well as its numerous applications in the packaging industry. It explains why flocking is the secret to engaging consumers and making products attractive.

- 1. Understanding Flocking

- Definition: What Is Flocking?

- History: A Brief History Of The Development Of Flocking

- General Process: Flocking Process Overview

- 2. The Advantages Of Flocking In Packaging

- Aesthetic Appeal: Adds To The Visual And Tactile Experience

- Protection: Flocking Of Packaged Items

- Versatility: Diversity Of Flockable Materials

- 3. Flocking Applications In Packaging

- Luxury Packaging: Perfume, Makeup And Jewellery Gift Sets

- Retail Packaging: Flocked Packaging In Retail

- 4. Flocking Techniques

- Electrostatic Flocking: Process And Advantages

- Beater Bar/Gravity Flocking: How And Why It Is Used

- Spraying And Transfers: Alternative Methods And Their Uses

- 5. Flocking In Combinations With Other Techniques

- Screenprinting: Flocking As A Complement to Screen Printing

- Embossing And Glitter: Bling Packaging

- 6. Sustainability In Flocking

- Environmental Materials: Recycled And Biodegradable Fibre

- Low VOC Adhesives: Water-based Adhesives Offer Many Advantages

- 7. Conclusion

1. Understanding Flocking

Definition: What Is Flocking?

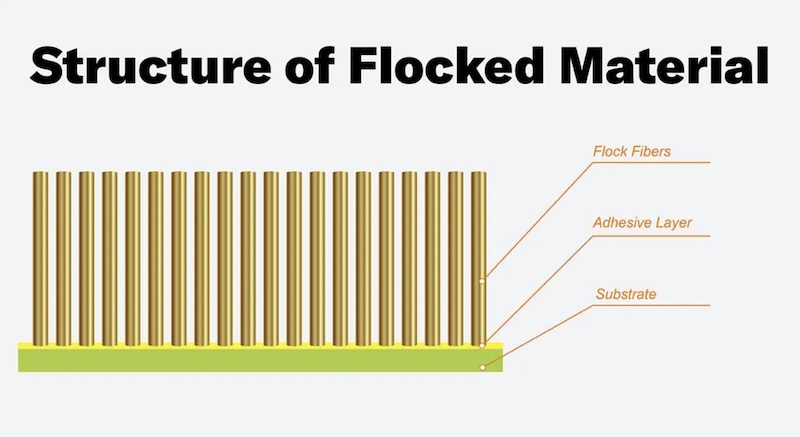

Flocking is the technique of coating an adhesive-covered surface with millions of tiny fibres to produce a velvet-like feel. This method is used to transform ordinary materials into luxurious, smooth surfaces that make products more appealing and useful.

History: A Brief History Of The Development Of Flocking

Flocking can be traced back 3,000 years to ancient China. It became popular for wall decorations in Nuremberg by the 12th century. In the 19th century, flocking was applied to wallpaper, and industrial production began in 1870. It gained popularity in the 20th century, being used in fashion, the automotive industry, and other consumer goods.

General Process: Flocking Process Overview

Flocking involves applying adhesive to a substrate (such as paper, plastic, metal or glass) and then overprinting it. The fibres are then charged by electrostatic flocking machines, standing upright and embedding into the adhesive at right angles. This produces a long-lasting textured surface. The fibres, which may be nylon, rayon or polyester, can vary in length and thickness to create textures ranging from soft velvet to bristle-like finishes.

2. The Advantages Of Flocking In Packaging

Aesthetic Appeal: Adds To The Visual And Tactile Experience

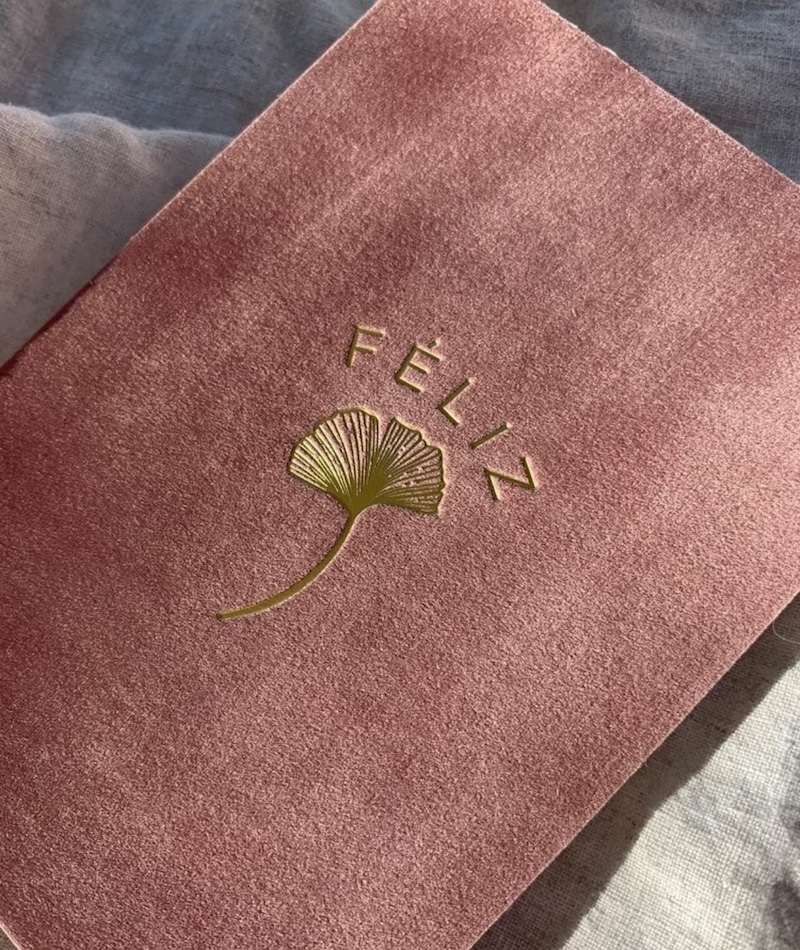

Flocking can transform ordinary packaging into a luxurious experience. The velvety texture is highly tactile and makes an impression. This sensory experience not only attracts customers, but also increases the perceived value of your product, making it stand out on crowded shelves.

Protection: Flocking Of Packaged Items

As well as improving the appearance of items, flocking also provides a protective lining. The fibres are soft and provide cushioning to protect delicate objects against scratches and damage during transportation. This extra protection guarantees that your products will be delivered in excellent condition, preserving their quality and attractiveness.

Versatility: Diversity Of Flockable Materials

Flocking is highly adaptable and can be used on a variety of materials, including paper, plastic and metal. This flexibility enables the application of flocking to various packaging types, including rigid boxes, folding cartons, custom-printed bags, and inserts. Flocking is a versatile and practical packaging solution.

3. Flocking Applications In Packaging

Luxury Packaging: Perfume, Makeup And Jewellery Gift Sets

Luxury packaging is enhanced with flocking. Bottles of perfume, makeup sets and jewellery sets acquire a luxurious look and feel that makes them more appealing. The velvet texture enhances the aesthetics and perceived value, making your products more appealing to discerning customers.

Retail Packaging: Flocked Packaging In Retail

Flocking offers many advantages in retail packaging. Flocked boxes or inserts can be used to package products ranging from electronics to gourmet foods. This improves the unboxing experience and provides added protection. Examples include flocked inserts in gift boxes and display trays for premium products, providing a unique and memorable customer experience.

4. Flocking Techniques

Electrostatic Flocking: Process And Advantages

This process involves applying fibres to a surface with adhesive using a high-voltage charge. The fibres stand erect, giving a dense, even texture. This technique provides a stable, long-lasting finish, making it suitable for high-quality, luxurious packaging. Close control of the electrical field ensures uniform coverage and high adhesion.

Beater Bar/Gravity Flocking: How And Why It Is Used

Beater bar or gravity flocking is a process involving a substrate to which adhesive is applied and then vibrated while fibres are sprayed onto it. This technique is ideal for achieving a heavier, more random application of the fibres. It is commonly used when a more tactile, less smooth finish is required and is therefore suitable for certain decorative purposes.

Spraying And Transfers: Alternative Methods And Their Uses

Spraying involves applying flock fibres using an air compressor, which is best suited to covering large areas quickly. This technique is effective, but it may result in less homogeneous fibre orientation. Transfers, however, consist of pre-cut flocked patterns that can be transferred onto other surfaces with ease and accuracy. Both approaches are flexible in regard to the needs of the project.

5. Flocking In Combinations With Other Techniques

Screenprinting: Flocking As A Complement to Screen Printing

Flocking can be used to enhance screen-printed designs with a rich tactile quality. For example, take a logo printed on a package using screen printing and give it a velvet texture. The result is an impressive visual and physical blend that captures the eye. Flocking can be used to fill in sections of a screen-printed design to make colours stand out and give them a three-dimensional quality that cannot be achieved with simple ink.

Embossing And Glitter: Bling Packaging

Flocking, embossing and glitter are the best way to make your packaging really stand out. Embossing creates a 3D effect by elevating areas of the surface, emphasising your design. Flocked surfaces can be covered in glitter to create a sparkling effect that draws the eye. Combining these methods provides a multi-sensory experience that is visually and physically appealing, ensuring your packaging is memorable.

6. Sustainability In Flocking

Environmental Materials: Recycled And Biodegradable Fibre

As sustainability becomes an increasingly important issue in packaging, flocking addresses this requirement by using environmentally friendly materials. Recycled and biodegradable fibres provide a green alternative without compromising quality. These materials ensure that your packaging is attractive and compliant with green ideals, appealing to environmentally conscious consumers.

Low VOC Adhesives: Water-based Adhesives Offer Many Advantages

Using water-based adhesives that contain low volatile organic compounds (VOCs) increases sustainability. These bonding materials minimise toxic emissions, making the flocking process safer for the environment and employees. They are also highly adhesive, ensuring that your flocked surfaces are strong and long-lasting without compromising their eco-friendly profile.

7. Conclusion

Flocking provides an attractive combination of beauty, protection and packaging flexibility. Its ability to transform ordinary materials into luxurious, tactile experiences makes it a valuable addition to any packaging strategy. Flocking is used to enhance the appearance and texture of luxury goods and car parts.

It's time to consider flocking your packaging. With the help of this technique, you will be able to distinguish your products, engage customers more effectively, and embrace sustainability.

Contact Winpack Printing for professional flocking solutions. Our skills will take your packaging to the next level.

About Printing Craftsmanship

What are eco-friendly printing options?

Vegetable-based inks instead of petroleum-based inks.

Recycled paper or sustainably sourced materials.

Water-based coatings instead of harmful chemical coatings.

Digital printing to reduce waste and energy consumption.

How do I ensure high-quality printing results?

Use high-resolution images and vector files.

Choose the appropriate paper or substrate.

Work with a professional printing service.

Consider color matching systems like Pantone for consistent results.

Request print samples before full production.

How does UV printing work?

UV printing uses ultraviolet light to cure ink instantly, resulting in vibrant colors, water resistance, and high durability. It is commonly used for packaging, signage, and promotional items.

OEM Services

What quality control measures do you have in place?

We implement strict quality control throughout our production process, including:

ISO-certified quality management systems

pressSIGN color management for consistent printing quality

ERP production tracking for precision and efficiency

Rigorous inspections at every stage of production

Folding Boxes

How long does it usually take from design confirmation to delivery?

Answer: The delivery time of folding boxes is usually 15-25 days, depending on the production of the order

Start Your Packaging Journey Today

Discover Our Curated Collection of Bespoke Packaging Cases & Tailored System Solutions

© 2025 WINPACK PRINTING. All rights reserved

Wenhua Printing packaging

winpackprinting

Winpack Printing