The Die Cutting Process in Packaging

Die-cutting is a popular manufacturing process in the packaging industry.

Chances are if you’re not a packaging expert, you probably don’t have a good idea of what the die-cutting process actually is.

Don’t worry, you’re not the only one!

Die-cutting has its origins in letterpress printing, and it evolved to become a more specific manufacturing process.

The die-cutting process in packaging utilizes a die to to cut materials into an array of different shapes, designs and patterns.

It’s most commonly used for, but not limited to, the manufacturing of folding carton packaging.

Die-cutting is used by businesses to create unique custom packaging tailored to their brand narratives and customer experience.

It is a very valuable process as it is easier, faster and more cost effective to produce custom packaging in larger quantities, making it a win-win situation for both manufacturers and businesses.

Here we will cover everything you need to know to get a better understanding of the die-cutting process.

1. What is a die?

To understand the die-cutting process, it is necessary to be familiar with the elements involved in the manufacturing process.

So, what exactly is a die?

A die is a special tool used to cut and shape packaging materials under pressure.

You can think of a die as a kind of mould that is formed in the required shape to cut your packaging.

The initial process of producing your own packaging involves shaping your die.

Tools and die makers are then used to create your die and place it on a press.

Once this is complete, you can begin die-cutting your initial batch of custom packaging.

2. Can dies be used more than once?

Yes, and it is actually recommended!

Producing dies for each design of packaging is very expensive. However, it is a one-off payment, and far better than long-term expenses.

Once a die has been made, it can be used in the press several times to produce large quantities of packaging, which is highly economical for your business.

For example, imagine you have three products in the same package structure, differentiated only by their artwork design.

Just one die is needed to make thousands of boxes.

Die-cutting is a useful technique for producing distinctive custom packaging that can become a staple of your brand story.

Although manufacturing custom dies may seem daunting, consider it an investment that will benefit your business!

3. Knowledge of the die-cutting process

Imagine a die-cutter is like a large cookie cutter that stamps your chosen material to create your own packaging.

Technological and manufacturing process advancements in die-cutting have enabled die-cut box designs to be created more effectively and accurately.

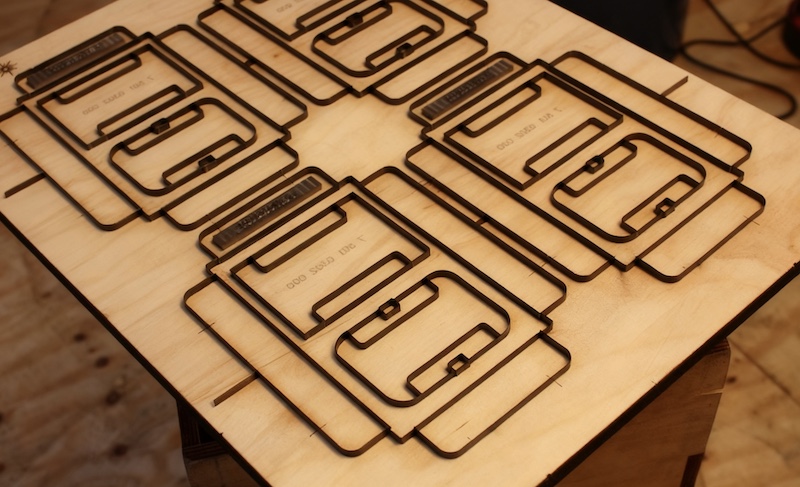

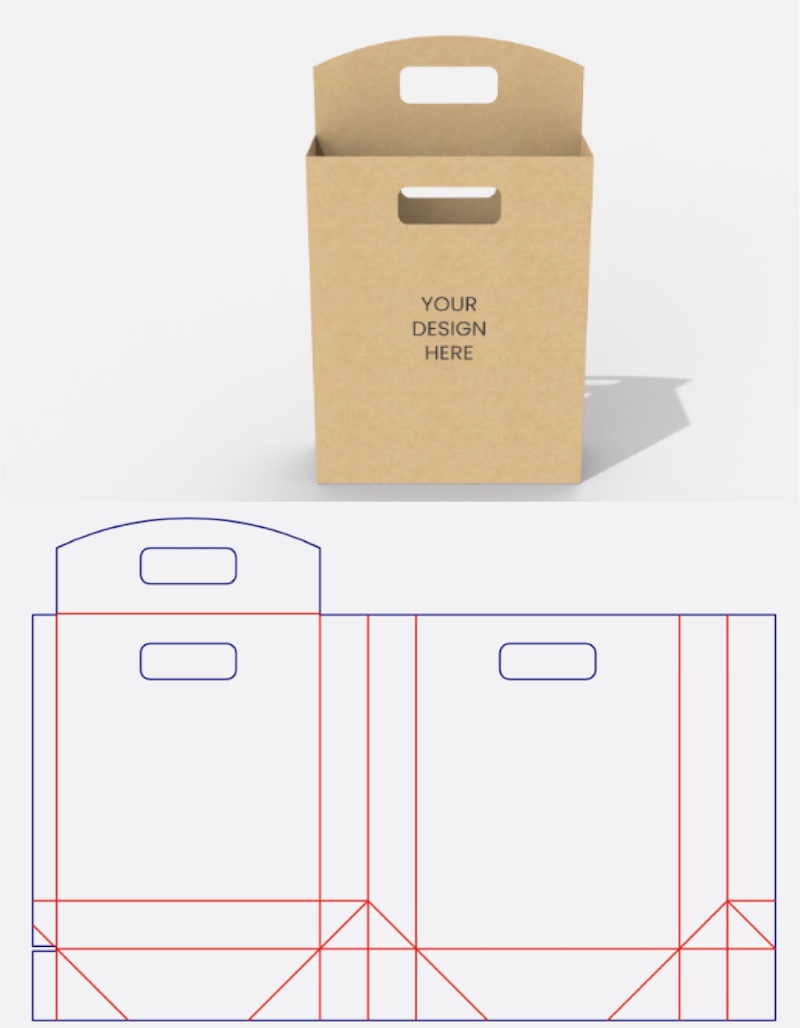

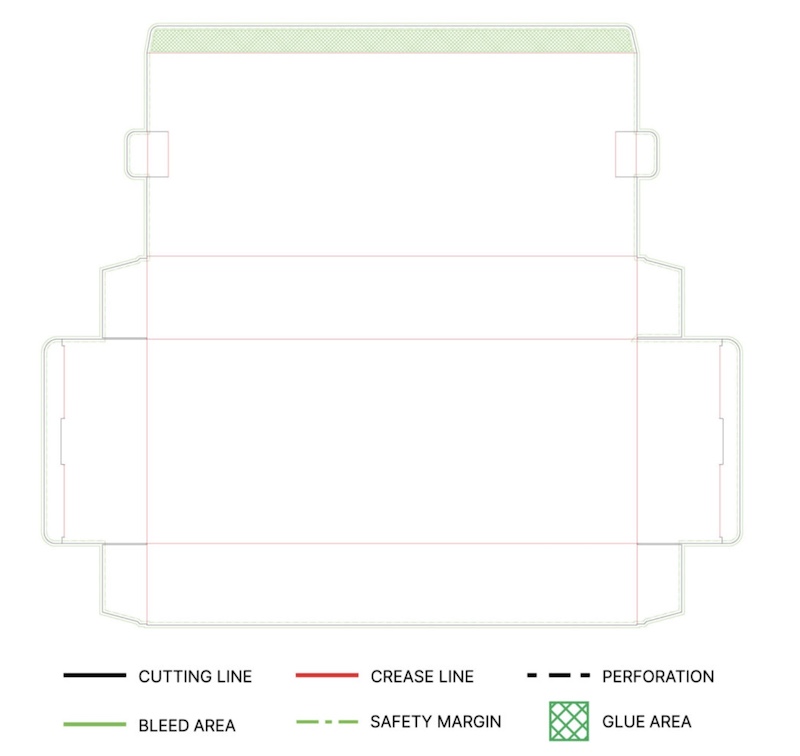

A packaging outline is usually designed using Computer-Aided Design (CAD), enabling you to transfer digitised drawings of your die line onto a wooden die board.

Laser cutters burn your dieline onto the surface of the die board, producing more accurate lines.

This is why it is important to ensure that the cut lines, fold lines, bleed lines and safe zones are properly mapped on your die line before proceeding with the die-cutting process.

Since the introduction of laser cutters in the preparation of die boards, the process of die-cutting has become more accurate and precise.

Die boards are placed below the material during die cutting to minimise movement and ensure precise cutting.

Die boards essentially guide the blade when it cuts through the material, ensuring the cuts are straight and precise.

Although this process is called die-cutting, it has numerous applications, such as:

Cutting: cuts through the material.

Scoring: impresses an impression or partial cut on a given area.

Folding: forms a fold line to make construction easier.

Perforating involves cutting a row of small holes so that the material can be torn easily.

All these functions serve a purpose in relation to various kinds of packaging materials and structural designs.

Corrugated packaging construction is particularly advantageous in this respect.

The die board is hammered with steel rules and a collection of foam and rubber parts to ensure the die bounces off the corrugated board during production.

This makes the crease lines more visible and creates a memorable impression that folds easily.

In terms of the die-cutting process itself, the die-cutting machine firmly presses the die into the material to cut out the desired shape, as programmed on the die and die board.

Any surplus material is then gathered and recycled where possible.

4. Die Cutting Methods

Although we discussed various functions in the process of reviewing the die-cutting process, it also involves various approaches.

These techniques open up a whole new realm of structural design possibilities and enable the creation of truly customised packaging.

There are many types of die-cutting method, including:

Blanking: The flat material is cut by making a slice on the outside. Blanking generates the correct level of flatness.

Drawing: The material is stretched to a specific length. This process is used in the production of lean, long packaging.

Forming: This involves bending the raw material on a curved surface. This process is usually combined with drawing to create rounded, cylindrical shapes.

Coining: Circular holes are created in materials by applying pressurised force to produce precise and detailed structural design elements.

Broaching: This involves cutting materials that are usually too hard or thick to cut with other tools. This is done using a series of large rows of cutting teeth.

The die-cutting process can be used on any packaging material, as shown in the list above.

5. The finishing touches

As stated above, the die-cutting process provides businesses with truly customised and unique packaging experiences.

Luxury packaging conveys a sense of sophistication, but it is costly to manufacture.

However, if you can afford to design your own high-end packaging, the die-cutting process can be used for that too!

The die-cutting process has the advantage of a wide range of finishing options that can be used to emphasise and add value to your die-cut design.

These include:

The die-cutting process makes custom packaging more affordable for both manufacturers and businesses. Although the initial setup costs may be high, this is offset by the fact that you will never need to pay that amount again for your specific design.

This process is highly accurate and efficient, generating large-volume orders quickly!

It also offers a variety of functions and options, enabling businesses to differentiate between custom and stock packaging and get creative with their packaging.

About Us

Can I get a sample?

Yes, currently sample free for reference, only need to pay the delivery charge. Customized sample charge sample fee and delivery cost.

Rigid Magetic Boxes

What are the wholesale pricing options for bulk orders?

We offer competitive wholesale prices for bulk orders. Please contact our sales team for more details

Rigid Lift-off Box

Can I print on the inside of the box?

Yes, you can print any effect you want on the inside.

How long does it usually take from design confirmation to delivery?

The lead time is usually 15-25 days, depending on the production of the order

Rigid Drawer Box

How long does it usually take from design confirmation to delivery?

The lead time is usually 15-25 days, depending on the production of the order

Start Your Packaging Journey Today

Discover Our Curated Collection of Bespoke Packaging Cases & Tailored System Solutions

© 2025 WINPACK PRINTING. All rights reserved

Wenhua Printing packaging

winpackprinting

Winpack Printing