What Is The Cost Of Custom Packaging?

Custom packaging plays a critical role in shaping brand perception, protecting products, and enhancing the overall customer experience—but one of the most common questions brands ask is: How much does custom packaging actually cost? Understanding packaging costs helps you make smarter decisions and avoid unnecessary expenses.

1. What Costs Are Included in Packaging?

Both new and established brands often face uncertainty when it comes to the cost of designing custom packaging. As a result, many choose stock packaging, which may fail to showcase the brand effectively and could negatively impact its reputation.

Custom packaging is designed to reflect your brand identity and create a memorable impression. However, its cost can be difficult to predict, especially for newcomers to the industry. Key factors that influence cost include:

-

Product type: Luxury goods, cosmetics, food, electronics, etc.

-

Industry application: Determines packaging requirements and customization needs.

-

Sales channel: E-commerce vs. retail packaging impacts structure and materials.

-

Launch timeframe: Some materials, like rigid packaging, require longer production.

Identifying these factors helps narrow down options and gives you a clearer idea of costs.

2. Material and Finish Costs

Materials and finishes are the first major expense in custom packaging, influencing structural design and printing costs. Common options include:

| Material Type | Cost Level | Characteristics & Finishing Options | Applicable Scenarios |

|---|---|---|---|

| Corrugated paper | Low | Durable, low-cost, easy to assemble, sustainable. Finishing options: varnish (cost-effective, fast delivery), lamination (high protection, high cost), wax coating (water/oil resistant, economical). No coating can further reduce costs. | E-commerce products, heavy or fragile items |

| Folding carton (white/SBS & kraft) | Low to medium | Lightweight, low shipping cost. Kraft paperboard is slightly more expensive than SBS white paperboard (SBS is made of bleached recycled paper). Finishing options: lamination (high quality, suitable for large orders), UV/AQ semi-gloss coating (cheap, food-safe). | Products with low protection requirements, such as cosmetics, light food |

| Rigid boxes | High | Made of high-quality thick greyboard, handcrafted, with a high-end texture. Finishing options: matte lamination (cost-effective high-end finish), specialty coatings (textured paper, embossing/debossing, foil stamping, etc., suitable for large orders with sufficient budget). | Luxury goods, high-end gifts |

| Box inserts | Varies by type | Cost levels from low to high: carton inserts < corrugated inserts < blister inserts < foam/molded pulp inserts. Molded pulp inserts are now expensive due to high demand for eco-friendliness. | Products requiring fixed protection, such as electronics, precision instruments |

3. Artwork and Structural Design Costs

If this is your first custom packaging project, artwork and structural design services may be necessary:

Artwork Design:

-

Complex designs cost more, but effective design communicates your brand story and engages customers.

-

Solution providers can manage design and production to optimize costs.

Structural Engineering:

-

Proper measurements and structure protect products and reduce material waste.

-

Standardized designs (corrugated slotted, folding carton tuck boxes, collapsible rigid boxes) help control costs.

-

Solution providers can combine structural and artwork services, simplifying project management and saving money.

-

-

4. Printing Costs

-

-

5. Manufacturing Costs

-

6. Logistics and Shipping Costs

-

-

Air shipping

Air freight is likely to be the preferred option for international deliveries as it is the fastest.Air carriers usually charge based on the weight and quantity of the items shipped.

The weight is determined by either the actual weight or the dimensional weight (i.e. the weight of the packaging and the item), whichever is greater.

Please note that air shipping may not be necessary depending on the location of your manufacturer.

Water shipping

Water shipping is another option, as it is cheaper than air transportation for heavy packages (more than 500 kg).Fees are calculated on a per-volume basis rather than a per-weight basis.

However, remember that this may not be the most time-efficient shipping process.

Therefore, if you need to launch your product quickly, this is a cost-effective but not necessarily the most optimal method of streamlining your custom packaging logistics.

-

Ground shipping

Ground shipping is the most popular delivery method, but it has its problems.The shipping price depends heavily on the dimensional weight of the item.

When calculating the shipping cost of your custom packaging, consider the weight and design of your boxes and how these factors affect ground shipping rates.

-

Would you like me to help you create a custom packaging cost budget template based on this summary, which you can fill in according to your product type and order quantity?

-

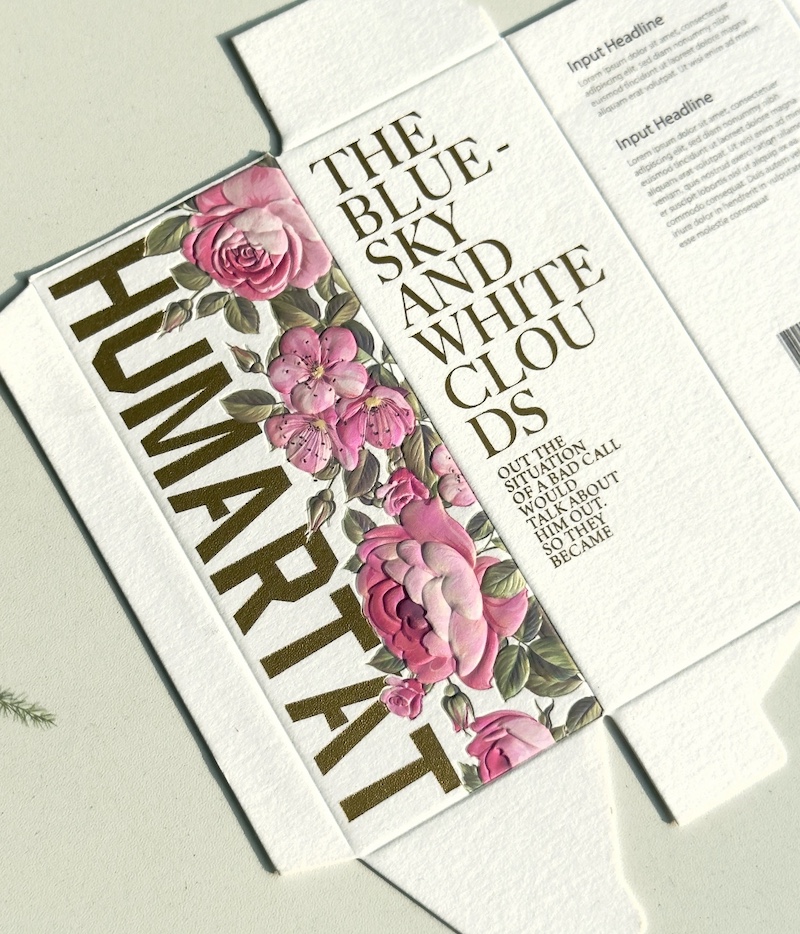

Rigid Magetic Boxes

Can I get a sample before placing an official order?

Yes, we provide samples to our customers. Please contact our sales team to inquire about sample availability and pricing.

About Us

Are you a manufacturer?

Yes, we are manufacturer, and we have over decade experience in this field.

How long does shipping take?

Air freight options range from 7-21 days, while ocean freight options range from 26-71 days. If you need some units expedited earlier, consider splitting your shipment between air and ocean!

OEM Services

What is the minimum order quantity (MOQ) for OEM orders?

Our MOQ varies depending on the type of packaging and material used. We offer flexible MOQ options to accommodate both small businesses and large-scale manufacturers. Contact us for a tailored quote based on your needs.

Special Shape Boxes

What are the wholesale pricing options for bulk orders?

We offer competitive wholesale prices for bulk orders. Please contact our sales team for more details

Start Your Packaging Journey Today

Discover Our Curated Collection of Bespoke Packaging Cases & Tailored System Solutions

© 2025 WINPACK PRINTING. All rights reserved

Wenhua Printing packaging

winpackprinting

Winpack Printing