Mastering Flexographic Printing in 2026: Advanced Packaging Solutions That Drive Performance

This comprehensive guide explores the state of flexographic printing in 2026, detailing the technology, ink types, and core benefits for modern manufacturing. It highlights the role of UV inks, sustainability, and high-speed production. The article also showcases how Winpack Printing utilizes advanced machinery like Heidelberg and Lithrone GL-40A presses to deliver superior custom packaging solutions.

- Introduction: The Power of Flexographic Printing in Modern Manufacturing

- How Flexographic Printing Works: The Core Process

- Key Components and Ink Transfer

- Understanding Ink Types

- Unrivaled Advantages of Flexographic Printing for Businesses

- Flexographic Printing Applications: Beyond the Basics

- Winpack Printing: Leveraging Flexography for Superior Custom Packaging

- Innovations and Future Trends in Flexographic Printing by 2026

- Choosing the Right Flexographic Printing Partner

- Conclusion: The Enduring Relevance of Flexographic Printing for 2026 and Beyond

- FAQs

- What is the main advantage of flexographic printing over other printing methods?

- What types of materials can be printed using flexography?

- Are flexographic inks environmentally friendly?

- How does flexography contribute to cost-effective packaging?

- What industries benefit most from flexographic printing?

- Can flexographic printing handle complex designs and multiple colors?

- What advancements are expected in flexographic printing in the coming years?

- How does Winpack Printing ensure quality in its flexographic custom packaging?

Introduction: The Power of Flexographic Printing in Modern Manufacturing

In the rapidly evolving landscape of industrial manufacturing, the demand for speed, precision, and versatility has never been higher. Flexographic printing explained simply, is a modern version of letterpress printing that has transformed into a high-speed rotary printing method. It utilizes flexible relief plates to transfer ink onto a wide variety of substrates, making it a cornerstone of the packaging industry.

While the technology evolved from humble beginnings, today it stands as a dominant force. As reported by Print Area Technology Co., Ltd., flexographic printing is defined by its use of a flexible relief plate and its capability for high-speed production, positioning it as a key industrial process alongside digital and offset methods. Whether for high-volume labels or complex custom flexographic packaging, this technology remains critical for businesses looking to scale their physical branding efficiently.

How Flexographic Printing Works: The Core Process

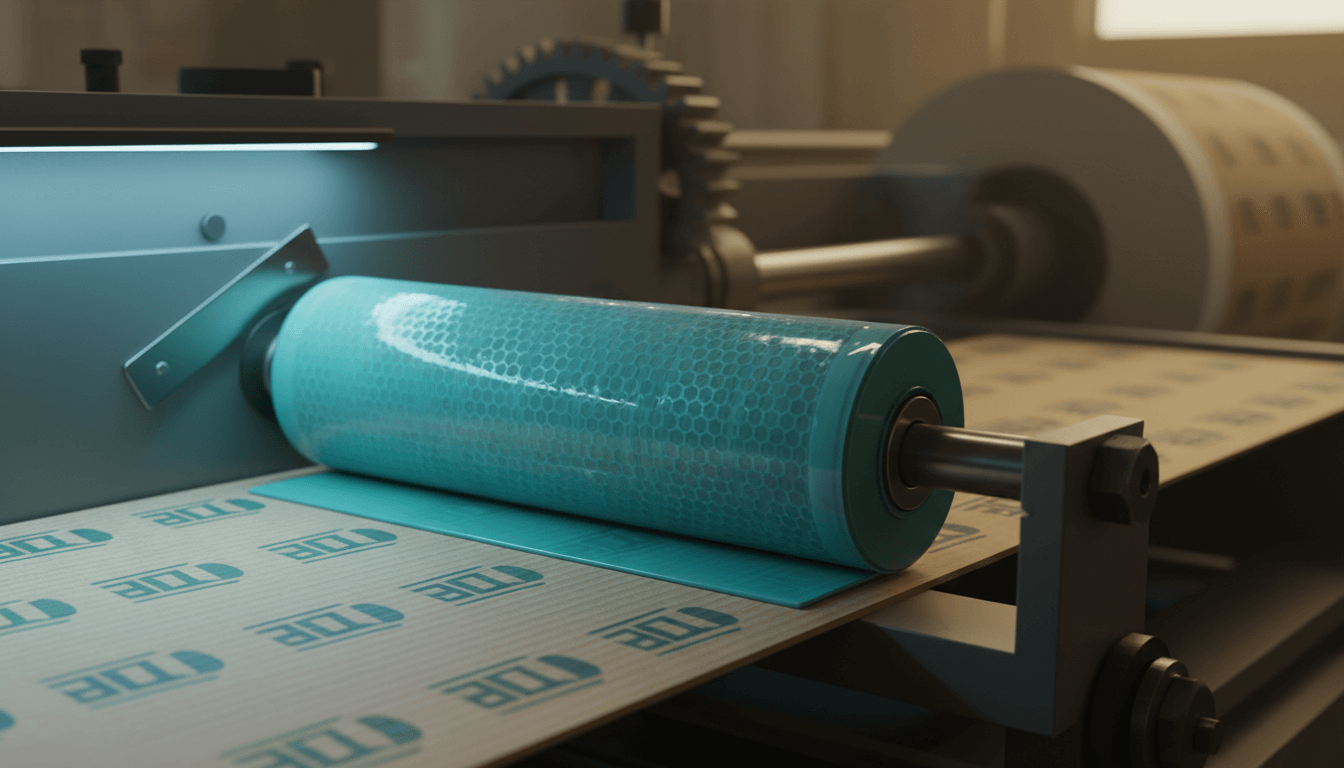

Understanding flexo printing technology requires a look under the hood of the press. The heart of the process is the flexible relief plate, typically made from photopolymer materials. The raised areas of this plate are what transfer the image to the substrate, a method that allows for incredible speed and adaptability.

Key Components and Ink Transfer

A standard flexographic press relies on a synchronized system of rollers:

· Fountain Roller: Picks up ink from the reservoir.

· Anilox Roller: A critical component engraved with millions of microscopic cells that meter the precise amount of ink needed.

· Plate Cylinder: Holds the flexible plate which receives ink from the anilox roller.

· Impression Cylinder: Applies pressure to transfer the ink from the plate to the material.

Understanding Ink Types

The choice of ink is pivotal. Flexographic ink types have expanded significantly, ranging from water-based and solvent-based to Electron Beam (EB) and Ultraviolet (UV) curing inks. According to industry insights from Fetching Printing, UV flexographic ink is particularly noteworthy for its environmental benefits. It employs ultraviolet light curing technology which eliminates volatile organic compounds (VOCs). Furthermore, these inks boast fast curing times, vibrant colors, and strong adhesion, ensuring durable finishes for packaging solutions flexography relies on.

Unrivaled Advantages of Flexographic Printing for Businesses

The benefits of flexo printing extend far beyond simple ink transfer. For modern businesses, particularly those in the Fast-Moving Consumer Goods (FMCG) sector, the advantages are tangible.

1. High-Speed Efficiency: Flexo presses are designed for speed, making them the most cost-effective option for long print runs.

2. Substrate Versatility: Unlike offset printing, flexography can print on almost any porous or non-porous substrate, including metallic films, cellophane, corrugated cardboard, and heavy carton board.

3. Durability: As noted by Wye LLC, flexographic methods are well-suited for various packaging materials like CCNB (Coated Clayback Newsback), which are commonly specified for rigid foldable boxes in industries ranging from electronics to footwear.

4. Cost-Effectiveness: Fast drying times and quick production speeds reduce overhead, offering significant savings on high-volume orders.

Flexographic Printing Applications: Beyond the Basics

Flexography is the engine behind many of the products we use daily. Its ability to print on flexible films makes it indispensable for food and pharmaceutical packaging. However, its application in rigid materials is equally impressive.

· Corrugated & Folding Cartons: Flexo is the standard for shipping boxes and retail displays.

· Labels and Tags: It handles variable data and high-definition graphics for branding.

· Specialty Packaging: From disposable cups to gift wraps.

At Winpack Printing, we leverage these capabilities to produce specialized items. Our expertise in paper box flexo printing allows us to craft high-quality custom gable boxes, gift boxes, beauty boxes, and display boxes that meet the rigorous demands of global retail markets.

Winpack Printing: Leveraging Flexography for Superior Custom Packaging

When it comes to Winpack printing solutions, technology and expertise go hand in hand. Established in 2016, Guangdong Winpack Printing Technology Development Co., Ltd. has grown into a leader in the field, operating a 15,000-square-meter factory equipped with state-of-the-art technology.

To ensure our custom flexographic packaging meets the highest standards, we utilize top-tier machinery, including the Heidelberg printing machine and the Lithrone GL-40A. These advanced presses allow us to execute precise, high-speed runs for diverse industries including cosmetics, food, healthcare, and electronics.

Our vision is to become the world's leading custom paper box manufacturer. Whether producing custom pillow boxes, window boxes, or rigid boxes, our integrated approach—covering design, proofing, and production—ensures that every unit reflects the quality our clients expect.

Innovations and Future Trends in Flexographic Printing by 2026

Looking ahead, the future of flexographic printing is bright and increasingly digital. By 2026, we anticipate several key shifts:

· Sustainability: A push towards water-based inks and biodegradable substrates to minimize environmental footprint.

· Automation: AI-enabled press automation will streamline workflows, reducing waste and setup times.

· Hybrid Solutions: The integration of digital printing units into flexo presses will allow for greater personalization and variable data printing (VDP) without sacrificing the speed of flexo.

· Enhanced Color Management: Advanced software will ensure absolute consistency across global supply chains, a crucial factor for major brands.

Choosing the Right Flexographic Printing Partner

Selecting a printing partner is about more than just price; it is about capability and reliability. You need a partner who understands material science and possesses the infrastructure to deliver.

Factors to consider include:

· Production Capacity: Can they handle peak season volumes?

· Technology: Do they use modern presses like the Lithrone GL-40A?

· Comprehensive Services: Do they offer design and proofing alongside printing?

Winpack's 15,000-square-meter facility and our dedication to utilizing advanced screen plate-making systems make us the ideal choice for complex, high-volume projects. We don't just print; we provide complete packaging solutions.

Conclusion: The Enduring Relevance of Flexographic Printing for 2026 and Beyond

As we move towards 2026, flexography remains an indispensable part of the global supply chain. Its unique combination of speed, versatility, and cost-effectiveness ensures it will continue to dominate the packaging landscape. From packaging solutions flexography provides to the intricate details of paper box flexo printing, this technology adapts to meet the needs of the future.

For businesses seeking reliability and quality, Winpack Printing stands ready to deliver superior custom printed paper packaging solutions, combining industry-leading expertise with the power of modern flexographic technology.

FAQs

What is the main advantage of flexographic printing over other printing methods?

Its primary advantage lies in its high-speed production capability, versatility across a wide range of substrates, and cost-effectiveness for large volume runs, especially in packaging.

What types of materials can be printed using flexography?

Flexography can print on diverse materials including various types of paper, carton board, corrugated cardboard, plastic films (like cellophane, polyethylene), metallic films, and aluminum foil.

Are flexographic inks environmentally friendly?

Modern flexographic printing increasingly utilizes eco-friendly water-based and UV-curable inks, reducing VOC emissions and aligning with sustainable practices.

How does flexography contribute to cost-effective packaging?

It achieves cost-effectiveness through high-speed production, efficient ink drying, and the ability to print on diverse, often less expensive, substrates, making it ideal for high-volume orders.

What industries benefit most from flexographic printing?

Industries like food and beverage, pharmaceuticals, cosmetics, and general consumer goods heavily rely on flexographic printing for labels, flexible packaging, and custom boxes.

Can flexographic printing handle complex designs and multiple colors?

Yes, with advancements in plate technology and enhanced color management systems, flexography can produce high-quality prints with intricate designs and multiple spot or process colors.

What advancements are expected in flexographic printing in the coming years?

Key advancements include increased automation, AI-enabled press technology, greater emphasis on sustainable materials and inks, and further integration with digital printing for hybrid solutions.

How does Winpack Printing ensure quality in its flexographic custom packaging?

Winpack ensures quality through state-of-the-art machinery like Heidelberg and Lithrone GL-40A presses, a 15,000 sqm factory, and a rigorous process of design, proofing, and production expertise tailored for custom paper box packaging.

OEM Services

Do you offer eco-friendly and sustainable packaging options?

Yes! We provide environmentally friendly packaging solutions, including recyclable, biodegradable, and FSC-certified paper materials. Let us know if you’re looking for sustainable options.

Can you help with packaging design if I don’t have one?

Yes! Our experienced design team can assist in creating packaging that aligns with your brand’s vision. We can develop concepts, offer material recommendations, and ensure compliance with industry standards.

About Us

How soon we can get a sample?

Usually,reference sample within 2 days. Customized sample need 5-7days.

Rigid Drawer Box

What are the wholesale pricing options for bulk orders?

We offer competitive wholesale prices for bulk orders. Please contact our sales team for more details

Can you provide me with a die-cutting line template?

We will provide a die-cutting line template after you place an order for samples or products.

Start Your Packaging Journey Today

Discover Our Curated Collection of Bespoke Packaging Cases & Tailored System Solutions

© 2025 WINPACK PRINTING. All rights reserved

Wenhua Printing packaging

winpackprinting

Winpack Printing