How Much Does Custom Packaging Cost?

Custom packaging plays a critical role in shaping brand perception, protecting products, and enhancing the overall customer experience—but one of the most common questions brands ask is, "How much does custom packaging actually cost?" Understanding packaging costs helps you make smarter decisions and avoid unnecessary expenses.

- 1. What Costs Are Included In Packaging Costs?

- 2. The Cost Of Finishes And Materials

- Corrugated

- Folding carton (white and kraft)

- Rigid boxes

- Other packaging materials

- 3. The Price Of Structural And Artwork Design Services

- Artwork design

- Structural engineering

- 4. Comparing printing costs

- 5. Cost of manufacturing

- 6. The logistics and shipping cost

- Air shipping

- Water shipping

- Ground shipping

1. What Costs Are Included In Packaging Costs?

Both established and new brands are uncertain about the cost of designing custom packaging.

For this reason, companies are likely to choose stock packaging, which does not necessarily do their brand justice and may consequently damage their reputation.

Custom packaging is designed to showcase your branding and create a memorable impression on your target market.

This is difficult to achieve when your competitors are probably using the same stock packaging.

The cost of custom packaging may be somewhat enigmatic, particularly if you are new to the industry, as it can be difficult to predict what will influence the cost.

Ultimately, it is up to you to decide how much to pay, and you can ensure that it fits your budget!

The first step in calculating your custom packaging prices is to identify the nature of the product you are selling.

This could include:

- Luxury products

- Cosmetics

- Food

- Electronics

- Or anything else!

Identifying the industry that your product will serve will enable you to reduce the number of options and consequently get a clearer idea of your costs.

This involves deciding how you will serve your industry niche.

The difference between e-commerce and retail packaging will also have a drastic impact on your pricing choices, since these packaging solutions are used for different purposes.

The cost of your product will also be influenced by the timeframe of your product launch, since some packaging materials may require more time and attention to manufacture (e.g. rigid packaging).

Once you have identified these factors, you can start comparing the core cost considerations of your custom packaging.

2. The Cost Of Finishes And Materials

When considering the cost of custom packaging, the initial expense will be the materials and finishes used.

These will limit your options as you decide on your structural design and printing costs.

There are numerous materials available, which differ in cost. You will have to pay for most of the costs of sourcing and shipping your packaging materials anyway.

The following is an estimated price list:

Depending on your product launch strategy, you might wish to consider cheaper packaging because it is much easier to produce.

In other cases, the best way to maximise your custom packaging is to not use the highest quality packaging materials.

It is important to understand the difference between what you want and what you need.

Consider this: you might want a Picasso original on your wall, but a printed copy would suffice.

Therefore, when you have a small business, it is better to seek a custom packaging company that will optimise your expenses and provide the minimum order quantity you require.

There are numerous cost-effective material options that will convey your brand narrative as well as the best quality packaging.

As mentioned earlier, the industry that your product serves and how it serves that industry will help you decide what material and finish to use on your custom box.

Once that has been decided, you will need to determine how much custom packaging you will require.

Smaller boxes are usually less expensive to manufacture and deliver, whereas larger boxes can be relatively inexpensive based on the minimum order quantity.

Generally, the larger your order, the less you pay per unit, but some materials are only cost-effective for small orders.

We will discuss and analyse your material and finishing choices and prices.

Remember that manufacturers will not advise you on material optimisation. However, solution providers will assist you in maximising your cost efficiency depending on your product requirements.

Corrugated

Corrugated material is the safest option and remains popular for custom packaging thanks to its durability and low price.

It is simple to assemble and can be used for a wide range of products. It is also cheap to manufacture, making it a flexible choice when selecting your material.

E-commerce companies widely use corrugated packaging because it is cost- and time-efficient to manufacture, as well as being sustainable.

Its thickness provides support for heavier items and maximum protection for delicate items.

Moreover, corrugated packaging has a wide range of finishing options.

These include:

- Varnish: for small to medium-sized corrugated projects, gloss varnish is recommended to enhance production efficiency, creating a faster turnaround time and a lower general unit cost.

- Lamination: laminated coating will protect your artwork, but can be costly depending on your budget.

- Wax coatings are economical and water/grease resistant. This type of coating may be required when packing food or medical items. However, remember that since corrugated packaging is made of organic substances, wax is not necessary for safely packaging food and medicine.

Although there are options for finishing corrugated packaging, this does not mean that you have to choose one. You may choose not to use any coating.

Not selecting any coating for your packaging will also keep your corrugated packaging expenses low.

Remember that corrugated packaging may not be necessary if your products are not highly susceptible to breakage.

Folding carton (white and kraft)

Folding cartons are a good option for those who want to save money on products that do not require a high level of support or protection.

If you want to keep shipping costs down, the best option is to use folding cartons, as they are lightweight, so you can place larger orders at a lower cost.

Please note that kraft paperboard is slightly more expensive than SBS white paperboard, so you will need to take these cost differences into consideration when designing your custom packaging.

Kraft paperboard is made directly from the source, which gives it its texture and feel, making it slightly more expensive than SBS white paperboard.

SBS white paperboard is made from bleached recycled paper, making it cheaper as it is a reused product.

The coating on SBS white paperboard provides a surface on which you can print high-quality finishes to present your brand identity.

Despite being your low-cost alternative, folding cartons can still look luxurious and high-end thanks to their printing and finishing options, not to mention your branding!

Thanks to the versatility and affordability of folding cartons, you can afford to spend a little more on special finishes and coatings.

These finishes include:

--Lamination

Laminated paperboard boxes are considered to be the highest quality and are usually more expensive due to the protection they offer. Lamination is mostly used in long-run projects because it is durable and resistant to dust.

--UV and AQ semi-gloss finishing

If you want something cheaper, consider a low-gloss AQ coating. As AQ semi-gloss is water-based, it is a food-safe alternative.

Folding cartons with a Kraft and AQ UV finish are cheaper. However, the price difference is not so great that you cannot use white kraft to improve printing and artwork designs.

Rigid boxes

Rigid boxes are ideal for those willing to pay a little more for high-quality packaging.

They are ideal if you need something durable and expensive. They are also the most expensive on the market.

They can be used for luxury goods to make the packaging feel more high-end and improve the customer experience.

In other words, rigid packaging is made from high-quality thick greyboard and is hand-constructed.

Rather than using a simple die-line to enable you to fold your packaging as you wish, rigid packaging is made by gluing each edge and surface manually.

This mat

erial is premium in price mainly because of the way it is constructed to create your packaging. It is also the slowest to produce.

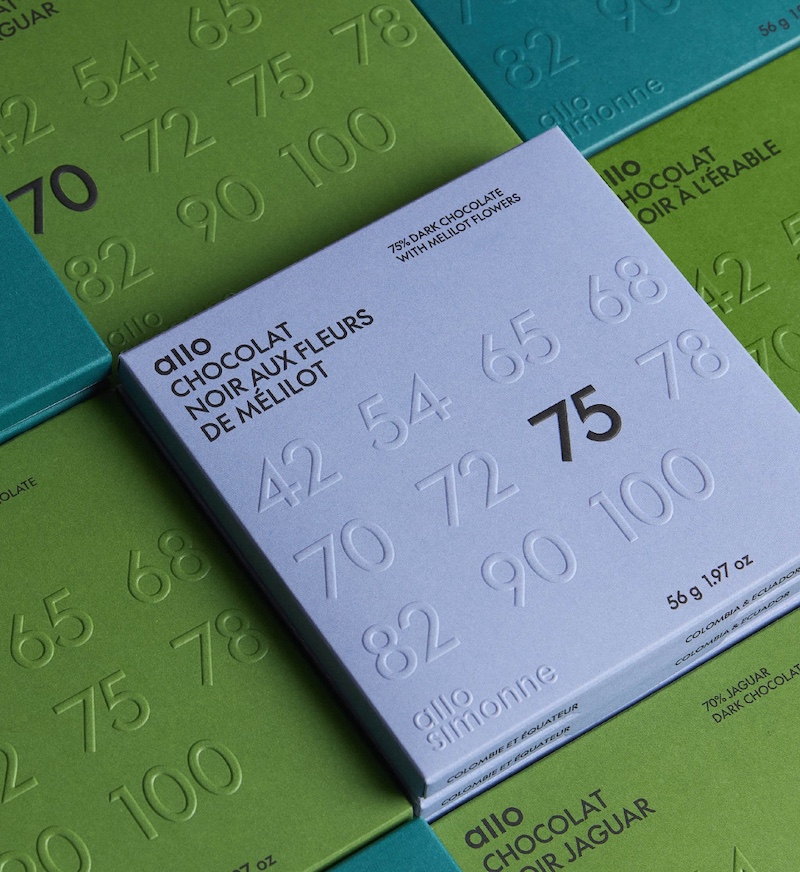

Luxury packaging is accompanied by special finishes and coatings.

--Matte lamination

The most recommended coating for luxury boxes is matte lamination. It imitates a high-end finish at a relatively low cost.

--Specialty coatings

You can also use specialty coatings if you have a large enough budget for packaging designs that require unique elements.

Such coatings are only recommended for large orders due to the additional expense. However, if budget is not an issue, why not?

Examples of specialty coatings include:

- Textured paper

- Embossed and debossed

- Pearlized coating

- Glittered

- Reticulated

- Scented

- Foil stamped

Although rigid packaging is the most expensive type, you can still save money with this material.

Adopting a minimalist approach to artwork design will also enable you to reorient your budget and save on extravagant expenditure on high-quality packaging.

Other packaging materials

To ensure that you do not incur any unforeseen expenses, we should consider other materials your products might require.

Some products may require additional assistance, particularly with regard to shipping, handling or stocking.

Of course, this also depends on your product and distribution method.

Box inserts

Box inserts are a low-cost way to provide additional support and protection for your products.

They are available in the following types:

- Carton (bleached and SBS white paperboard): This is the least expensive option and offers less protection, but still provides structure, printing and finishing options. Kraft paperboard is slightly more expensive than SBS paperboard.

- Corrugated inserts are cheap and can be printed and finished if you want to print the inside of your package.

- Blister: non-recyclable, made of plastic and moulded to the shape and size of your products. However, it is not as cost-effective to produce.

- Foam inserts are the most expensive option, but they provide the best cushioning for your products and are commonly used for luxury items.

- Molded pulp inserts are the most expensive option as they are moulded to the shape of your products and are 100% recyclable. Molded pulp was previously a cost-effective box insert. However, they are now very expensive due to the increased number of eco-conscious shoppers and the fact that they are produced using raw materials.

3. The Price Of Structural And Artwork Design Services

You might even have your packaging's design and structure prepared.

If this is the case, then this cost consideration may not apply to you.

However, if this is the first time you have designed your own packaging, chances are you will need artwork and structural design services to help you build your packaging project.

It is worth mentioning that manufacturers will not assist you in sourcing these services; you will have to do so yourself.

This could be more expensive in the long term, as you will be paying a premium to a range of different companies for your packaging.

However, solution providers can assist with complete project management, including cost optimisation and artwork and structural design services.

Paying a solution provider will eventually save you money, since you will only be paying one business rather than a number of them.

This also simplifies your costs and saves you a great deal of time on your packaging project.

Artwork design

The design of your artwork can affect the cost of custom packaging.

Your artwork design must be able to convey your brand story and attract your target market. The more complex your design ideas, the higher the cost.

The packaging design market is highly competitive, so artwork design services can be expensive.

However, this does not mean that you should opt for minimalism to ensure the success and economic viability of your packaging.

Using cost-effective materials with high-quality printing and finishing will improve your designs, depending on the printing method used.

If you use a design service that does not manufacture, you will pay a premium for your artwork designs. Only a few design services provide structural engineering, and this will be expensive as well.

However, solution providers can help you reduce your design service expenditure because you are dealing with a single firm for all aspects of your project.

Structural engineering

It is also advisable to consult a structural engineer to ensure that you are maximising your product packaging.

Although standard shapes can be used for packaging, the measurements are important for the safety of your products and your budget.

Remember that the size of your packaging is determined by the interior size.

Properly measuring your product will ensure that you pay the least possible for materials and the most for protecting your products.

Manufacturers will not recommend measurements or structures. Nevertheless, solution providers can offer structural design services and advise on the best way to optimise your packaging to protect your products.

If you are considering more complicated structural designs, structural engineers can make them practical by optimising them for the real world.

By collaborating with a solution provider, you can reduce your structural engineering expenses, as you will only be dealing with one company for all aspects of your packaging.

Structural design services are generally not as expensive as you might imagine, particularly when dealing with solution providers.

Let us explore some popular packaging structures and how you can maximise your budget.

--Corrugated

As mentioned above, corrugated packaging is one of the most popular packaging materials.

But what about the structure?

Although most people use the following designs, particularly when it comes to e-commerce or subscription box companies, the design is also up to you.

- Periodic slotted corrugated packaging.

- Complete overlap corrugated packaging.

- Corrugated open-end packaging.

Corrugated packaging is a cost-effective alternative in itself. In this case, the price will be influenced by the structure to a minimum extent.

Another excellent way to ensure that corrugated packaging is not expensive is to use a standardised structural design, such as those mentioned above.

--Folding cartons

The possibilities for your folding cartons are almost unlimited.

Folding cartons are such a versatile type of packaging material that your packaging can be made to almost any size or shape you desire!

However, you can reduce the cost of your packaging significantly by adhering to standardised structures, as would have been the case had you chosen kraft folding cartons instead of white ones!

Examples of popular structures include:

- Reverse tuck end

- Straight tuck

- Pillow boxes.

The low cost of folding cartons involves using standardised structures, which are simple to build and produce.

--Rigid

Rigid boxes, as discussed above, are the most expensive to produce due to the construction process and quality of materials used.

Since this type of packaging is usually the most expensive, your designs can be extremely complicated and distinctive.

Nevertheless, even rigid packaging has certain standard structures.

These include:

- One-piece magnetic boxes

- Two-piece rigid boxes

- Collapsible rigid boxes

Collapsible rigid boxes are the most suitable choice if you want to keep the cost of rigid packaging low.

Since they save you a lot of space, you will save on shipping and warehousing expenses while still enjoying the same high-quality feel as with rigid packaging.

Instead of using several pellets to package your products for shipping, you can use one or two to maximise your savings.

4. Comparing printing costs

One of the key reasons why companies decide to go with custom packaging is the ability to print their own branding directly onto their product packaging.

The printing method is entirely a matter of taste.

The packaging industry offers several popular printing methods.

There are three main options for printing on custom packaging:

- Digital printing: This is mostly used for smaller orders and involves applying the design directly to the box.

- Offset printing: This method uses a printing plate and rubber cylinder to print the design on the package. The resolution and finish are higher, though it is more expensive.

- Flexographic printing: The design is stamped directly onto the box (as in digital printing) using a printing plate. However, this method is costly as each plate is expensive. It can only hold one colour, so it is best used for bulk orders.

Small-to-medium-sized businesses will largely prefer digital printing since it is reasonably priced for small quantities.

It is also time-saving and offers unlimited design possibilities.

Small, simple designs are best achieved through digital printing. Complicated designs are best achieved through offset printing due to its quality.

However, the quality difference is very drastic and offset printing can be expensive.

Offset printing allows you to produce high-quality prints of your artwork. Although the price difference between digital and offset printing is significant, you will save money if you decide to print high-volume orders.

Offset printing is more cost-effective for high-volume orders since the setup cost is significantly reduced.

Although it might be tempting to opt for digital printing to save a few pennies, compromising the quality of your design can say a lot about your brand.

In most cases, it is advisable to use higher-quality printing techniques, such as offset printing, to maximise the quality of your packaging.

However, digital printing can still be used for less complex designs.

5. Cost of manufacturing

As mentioned previously, manufacturers and solution providers have different needs.

Therefore, you need to identify which of the aforementioned services you require to package your products.

Solution providers offer a complete packaging service, including manufacturing.

In terms of price, you are paying a premium to have the entire ideation-to-delivery process offered by one company.

Manufacturers, on the other hand, merely respond to your orders. You are responsible for everything, including placing your order.

Most importantly, you will be responsible for ensuring that your manufacturer conducts quality control tests.

For example, in the case of corrugated packaging, it is worth conducting an edge crush test to ensure that your packaging meets your requirements.

This may also mean that your options are limited to a smaller pool of manufacturers, as geographic location becomes an issue.

Ideally, when sourcing a manufacturer, you would prefer them to be nearby so that shipping and logistics are easier to monitor and maintain.

Furthermore, you will want to be able to test a sample or prototype before giving the manufacturer the go-ahead to start production.

However, it may seem cheaper to simply make do with one manufacturer and pick the other services you need individually.

Ultimately, you will end up paying a lot more than if you paid one premium for all your services.

What's more, it is much easier to manage your packaging project since all your processes are contained in a single area.

6. The logistics and shipping cost

Shipping and logistics should also be a major part of your budget when determining the cost of custom boxes.

The design of the packaging structure also depends on how you are going to ship your products because their weight and dimensions contribute significantly to shipping expenses.

Once you have some approximate numbers, you can estimate the shipping and packaging costs for various modes of transport.

Remember that you may need to outsource services to ensure your logistics are designed to support your product launch.

Logistics are particularly important for your business when you decide to work with manufacturers rather than complete project cycle providers.

This could result in increased end costs.

Air shipping

Air freight is likely to be the preferred option for international deliveries as it is the fastest.

Air carriers usually charge based on the weight and quantity of the items shipped.

The weight is determined by either the actual weight or the dimensional weight (i.e. the weight of the packaging and the item), whichever is greater.

Please note that air shipping may not be necessary depending on the location of your manufacturer.

Consider one of the other shipping options listed below to avoid breaking the bank on packaging.

Water shipping

Water shipping is another option, as it is cheaper than air transportation for heavy packages (more than 500 kg).

Fees are calculated on a per-volume basis rather than a per-weight basis.

However, remember that this may not be the most time-efficient shipping process.

Therefore, if you need to launch your product quickly, this is a cost-effective but not necessarily the most optimal method of streamlining your custom packaging logistics.

Ground shipping

Ground shipping is the most popular delivery method, but it has its problems.

The shipping price depends heavily on the dimensional weight of the item.

When calculating the shipping cost of your custom packaging, consider the weight and design of your boxes and how these factors affect ground shipping rates.

Ground shipping is highly reliant on packaging size since shipments may need to be divided.

Think of it this way: if you have 500 oddly shaped boxes that cannot be stacked very well, you may need more than one van or truck to ship your packaging.

This also affects your custom packaging costs, as you may end up paying more for ground shipment than anticipated.

Bear in mind that ground shipping is only an option if the manufacturer is fairly close to you; otherwise, you may need to opt for air or water shipping instead.

When estimating the cost of designing packaging and the cost of custom boxes in general, remember that shipping and logistics play a large role in raising your end costs.

While you may think you’re getting a bargain with your custom designs and packaging, your logistics could make you think again.

That’s why it’s important to consider shipping and logistics before entering the manufacturing process.

Once you have a clear idea of what you want, you’ll be able to estimate the shipping costs more accurately.

It is essential to consider the weight of the custom packaging when estimating costs, as well as the volume being created, in order to choose the right type of box and printing for your budget.

If you are unsure about the cost of designing and shipping packaging, you can request a quote for an exact estimate of your packaging needs.

About Printing Craftsmanship

What is the difference between offset and digital printing?

Offset Printing: Best for large-volume production, offering high-quality prints at a lower cost per unit.

Digital Printing: Suitable for short runs, allowing quick setup, customization, and fast printing.

OEM Services

What types of packaging products do you offer?

We specialize in a wide range of packaging solutions, including:

Custom labels and stickers

Paper bags and gift boxes

Beauty and cosmetic boxes

Food and beverage packaging

Pharmaceutical and healthcare packaging

Jewelry, electronics, and toy packaging

Luxury and high-end packaging solutions

If you have specific requirements, we can customize products to fit your needs.

Can I request a sample before mass production?

Yes, we provide sample proofing before mass production to ensure that the design, materials, and quality meet your expectations. We encourage testing and approval before proceeding with full-scale manufacturing.

Folding Boxes

I need a folding box with a special shape, can it be customized?

Yes, folding boxes can be customized with special shapes according to product requirements. Through the die-cutting process, folding boxes of different shapes and structures can be produced.

About Us

How long does shipping take?

Air freight options range from 7-21 days, while ocean freight options range from 26-71 days. If you need some units expedited earlier, consider splitting your shipment between air and ocean!

Start Your Packaging Journey Today

Discover Our Curated Collection of Bespoke Packaging Cases & Tailored System Solutions

© 2025 WINPACK PRINTING. All rights reserved

Wenhua Printing packaging

winpackprinting

Winpack Printing