4 Types of Grades paperboard packaging

Many industries, such as food and beverage production, pharmaceuticals and retail, require packaging. Packaging plays an essential role in protecting products, and the material used must be durable enough to enable it to perform this function. Paper grading is one of the most important factors influencing the quality and durability of packaging.

Different types of paper grading have different properties that affect the strength, durability and cost of packaging. Businesses need to understand the pros and cons of each alternative in the paper industry to select the most suitable type of packaging for their products.

This paper discusses four popular types of paper used for packaging: kraft paper, corrugated board, solid bleached sulphate (SBS) paperboard and coated paper. We will also explain the benefits of each grade of paper and compare their respective strengths, durability and cost, to help businesses make informed choices about packaging materials.

However, before we discuss the various grades of paper used for packaging, it is worth mentioning that choosing the right packaging material can greatly affect a company's environmental impact. Using green packaging materials such as paper can minimise carbon emissions, waste, and energy use, as opposed to plastic or other non-renewable materials.

Consequently, plant-based packaging solutions are becoming increasingly popular among companies as part of their sustainability efforts. With this in mind, we will now take a closer look at the most popular types of paperboard.

What is paperboard?

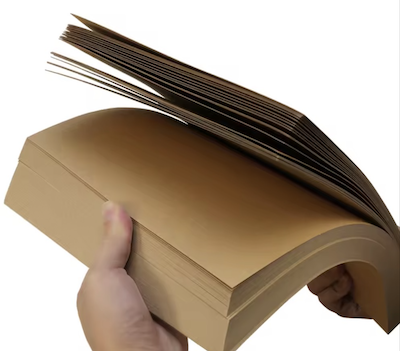

Paperboard is a strong, flexible paper-based packaging material formed by compressing sheets of paper pulp fibres to create a dense, stiff board. Paperboard can be designed to meet various packaging requirements, including for food, cosmetics and retail products.

It is environmentally friendly and recyclable, making it the best solution for sustainable packaging. It is available in various grades, thicknesses, and finishes ranging from uncoated to matte to glossy.

Paperboard vs cardboard:

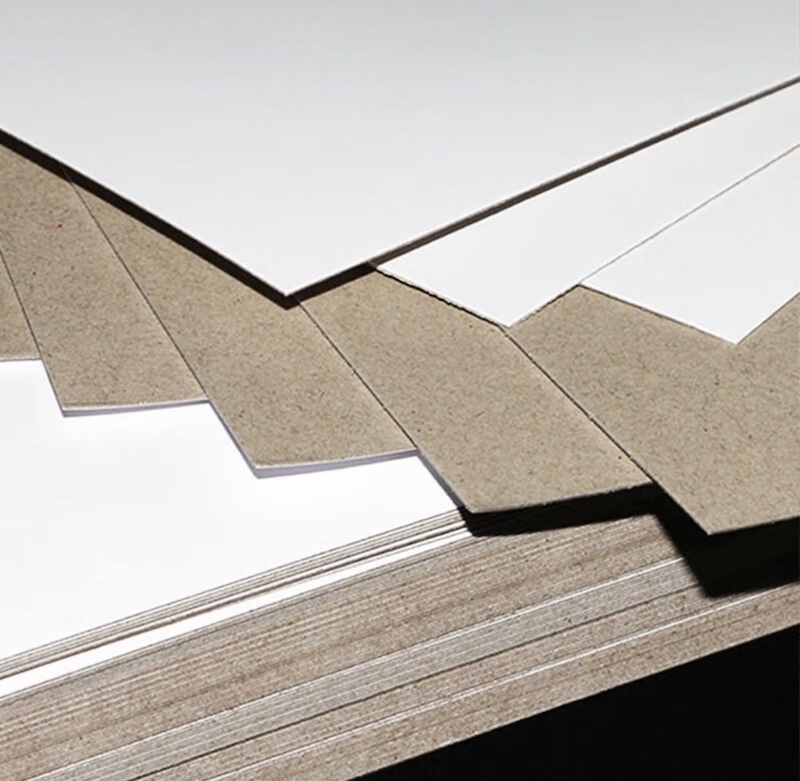

Paperboard and cardboard are two examples of widely used packaging materials in different industries. Although they seem similar, there are certain major differences between them.

Paperboard is a heavy, thin and strong material composed of compressed paper fibres. It is commonly used for food, cosmetics, and pharmaceutical packaging.

Cardboard, on the other hand, is a denser, more rigid material composed of several layers of paper, and it may also contain other materials, such as plastics. These layers usually consist of two liner boards and a corrugated board.

Paperboard and cardboard are two packaging materials used in different industries. Although they seem similar, there are important differences between them.

As discussed above, paperboard is a strong, lightweight material composed of compressed paper fibres.

Cardboard, on the other hand, is a solid, sturdy material composed of several layers of paper and other materials, such as plastics. Multilayered types are usually characterised by two liner boards and a single corrugated board, making cardboard more appropriate when structural strength is required.

While both paperboard and cardboard have their own advantages, businesses must consider the weight of the product, shipping distance, and durability when choosing between them. Ultimately, the choice of packaging material depends on your needs and requirements.

Popular paperboard grades

Now that you are aware of what paperboard is and how it differs from cardboard, we can discuss the four most popular types of paperboard used in packaging. Each grade of paper has its own benefits in terms of strength, durability, and cost-effectiveness, and can be used for various packaging applications.

In order to select the most suitable material with which to package their products, it is important that businesses understand the nature and advantages of each paper grade.

Clay-coated news backboard (CCNB)

CCNB is a type of paperboard produced using a mixture of recycled newsprint, mixed secondary paper and used corrugated containers. Due to its lower tensile strength and printing capacity, CCNB is commonly used for low-cost folding carton packaging for products such as dry food, pet food, laundry detergent and other non-food items.

However, CCNB paperboard boxes absorb large amounts of water in wet conditions, so they cannot be used for products requiring greater moisture or weight resistance. Nevertheless, CCNB is a relatively inexpensive alternative and is often used by low-end cereal brands for packaging.

CCNB is also an environmentally friendly option for businesses looking to minimise their environmental impact. As it is made of recycled materials, CCNB reduces the need for new virgin paperboard manufacturing, which can lead to deforestation and other environmental issues. Also, the recycled materials used in CCNB lead to fewer waste materials ending up in landfills, which contributes to a more circular economy.

However, it should be noted that the clay coating on CCNB can complicate the recycling process, even though the material itself is recycled. Not all recycling plants can separate the paperboard and clay effectively, which can contaminate other recycled products.

Nevertheless, companies can continue to contribute positively to the environment by using CCNB and other recycled paperboard grades while seeking other sustainable packaging materials and processes.

Solid Bleached Sulfate (SBS)

SBS is a high-quality paperboard grade commonly used in packaging. According to Statista, North America supplies 71 per cent of the global SBS market, which is used for retail product packaging.

The process of making SBS involves chemically pulping the fibres and bleaching them until they are pure white. The white wood pulp is refined and moulded into boxes.

SBS packaging is the most appropriate for products due to its high strength and durability, as well as the white interior and exterior of the box. This makes it ideal for printing, as it can be coated on one side (C1S) or both sides (C2S), giving businesses flexibility in their packaging design and printing requirements. Special processes such as embossing, debossing, hot foil stamping and spot UV printing are also possible since SBS is of a high quality.

SBS boxes are especially popular for cosmetics and personal care products as they look classy and luxurious. Nevertheless, such boxes are also common in food, pharmaceuticals, confectionery, baked goods, tobacco and other industries.

However, a significant drawback of SBS is that it is not environmentally friendly. SBS is produced through extensive bleaching, which can result in the release of harmful chemicals into the environment. Furthermore, virgin fibres are typically used in the production of SBS, meaning this type of paperboard has a significant impact on deforestation, a serious environmental problem.

Another disadvantage of SBS is that, unlike other grades of paperboard, it is relatively expensive and therefore not easily accessible to small businesses or those on a tight budget.

SBS cannot be used to package products subject to moisture or wet environments as it is not water resistant. Even though SBS is high quality, it may not be suitable for products that require heavy-duty protection. In such situations, other grades, such as corrugated board, are more suitable.

Folding Box Board (FBB)

FBB is a high-quality paperboard grade produced using multi-ply paper pulp materials, which makes it strong and durable.

Compared to SBS, FBB's mechanical pulp composition offers greater firmness, making it a popular choice among businesses that require packaging capable of withstanding wear and tear during transportation and storage. Furthermore, the multi-ply structure of FBB provides the ideal surface for offset printing.

FBB boxes are flexible and suitable for numerous industries, such as food, cosmetics, and pharmaceuticals, and are common in India as the main packaging medium for businesses.

However, although FBB is a great packaging option because of its strength and printability, it also has its drawbacks. Firstly, FBB is more expensive than other grades of paper due to its high-quality production.

Furthermore, FBB is not as environmentally friendly as other types of paper, including recycled paper, due to the use of virgin fibres. However, despite requiring virgin fibres, a number of FBB producers are starting to employ sustainable forest management and offer recycled paper content, reducing this environmental impact.

A second environmental drawback of FBB is that it is not easily recyclable as it is multi-layered. Although FBB can be recycled in many recycling plants, the recycling process can be more energy-intensive than that of other types of paper, which affects its overall environmental impact.

Nevertheless, these shortcomings have not stopped businesses from using FBB to package their products because of its strength and durability, and its ability to be printed on using custom printing to produce high-quality results.

Natural Kraft (SUS) and Coated Unbleached Kraft (CUK)

paperboard are emerging as popular environmentally-friendly options in the packaging industry, offering a more natural appearance and feel.

These grades of paperboard are emerging as popular choices in the packaging industry thanks to their environmentally-friendly nature and natural appearance and feel.

These grades are produced using recyclable materials, including unbleached wood pulp. The combination of unbleached pulp and recycled materials also makes SUS and CUK a perfect fit, as companies seeking sustainable packaging solutions should also consider uncoated papers, as they are very easy to recycle.

The natural brown colour of these grades of paperboard is one of their main characteristics and provides particular aesthetic value. However, this natural colour may be a disadvantage for products that require a more vibrant colour.

Nevertheless, SUS and CUK have numerous benefits and are popular in many packaging solutions.

SUS is often coated with naturally occurring clay to provide a smooth, printable surface. This coating is also somewhat waterproof, making it a good option for packaging products that might be exposed to moisture.

Alternatively, CUK is most commonly coated with polyethylene (PE) resin, which makes the paperboard more tear-resistant, durable, and water- and grease-resistant.

However, these grades of paperboard are not as strong as other grades, such as SBS or FBB, despite having some tear resistance. Furthermore, the more natural and textured appearance of these grades of paperboard may not lend itself to special effects such as embossing, debossing or foil stamping. Nevertheless, despite these drawbacks, SUS and CUK are excellent options when a company requires a food-safe package or wishes to achieve a more natural look and feel.

Fashionable paper packaging finishes

When it comes to paperboard packaging, the finish is as important as the grade of paper selected. The following are some of the most common finishes used for paper packaging:

Matte finish: Matte paper packaging has a soft, non-glossy appearance that looks sophisticated and high-end. It is commonly used for luxury products such as cosmetics, perfumes and high-end food items.

Gloss finish: Glossy paper packaging has a reflective, glossy finish, giving it a smooth, contemporary look. It is widely used for advertisements, magazine covers and retail packaging.

Embossed finish: Embossed paper packaging has a raised or recessed texture that creates a three-dimensional effect. This gives the packaging depth and texture, making it more memorable and interesting.

Foil stamping: Foil stamping involves using metallic or coloured foil on paper packaging to create a luxurious and sophisticated appearance. It is commonly used for high-end packaging of luxury goods such as chocolates and wines.

Spot UV coating: This process involves applying a high-gloss finish to certain parts of the paper packaging, creating a contrast between glossy and matte finishes. This emphasises specific areas of the packaging, such as logos, text or images.

What's more...

To know which grade of paper to use for your packaging, it is important to understand how durable, strong and thick the material is. Knowing these specifications will help you design an appropriate box for the weight of the product and the construction of the packaging.

The thickness of the paperboard is measured by determining its PT/GSM. Generally, the higher the GSM/PT unit, the greater the weight that can be supported and the thicker the material.

About Us

Can I get a sample?

Yes, currently sample free for reference, only need to pay the delivery charge. Customized sample charge sample fee and delivery cost.

What are your lead times?

Production typically takes 12-16 days, and 16-21 days for larger volume orders. Shipping times will depend on the shipping channel you choose.

Rigid Magetic Boxes

Can I get a sample before placing an official order?

Yes, we provide samples to our customers. Please contact our sales team to inquire about sample availability and pricing.

OEM Services

Can I request a sample before mass production?

Yes, we provide sample proofing before mass production to ensure that the design, materials, and quality meet your expectations. We encourage testing and approval before proceeding with full-scale manufacturing.

About Printing Craftsmanship

What is hot stamping, and where is it used?

Hot stamping is a printing process that applies metallic or pigmented foil to a surface using heat and pressure. It is widely used for:

Luxury packaging (cosmetics, wine, gourmet foods)

Business cards

Event invitations

Labels and stickers

High-end stationery

Start Your Packaging Journey Today

Discover Our Curated Collection of Bespoke Packaging Cases & Tailored System Solutions

© 2025 WINPACK PRINTING. All rights reserved

Wenhua Printing packaging

winpackprinting

Winpack Printing