Flexible Packaging – The Master Guide

Flexible packaging is becoming increasingly popular in the packaging industry, offering a flexible solution to the various requirements of many sectors. In fact, this type of packaging accounts for 19 per cent of the 177 billion U.S. packaging market, making it the second largest market in the United States. This statistic indicates not only the large market share of flexible packaging, but also its increasing significance in the industry.

The ability to accommodate various types of products, sizes and applications has contributed to this growing trend, which is particularly prevalent in the food, pharmaceutical and personal care sectors. These industries benefit greatly from the flexibility of packaging solutions because of the ease of use, storage, longer shelf life and sustainability, making them a versatile choice for businesses and consumers alike.

In fact, a Harris Poll survey revealed that 71 percent of participants indicated a preference for flexible packaging over rigid boxes. Of those aware of the packaging alternative, 79 percent were willing to pay an extra 14 percent for this convenient, hygienic choice.

Given the rapid increase in market share, business preference and consumer preference, it is clear that this packaging solution will continue to establish itself as the preferred choice in most industries.

So, if you are considering using flexible packaging for your product, you have come to the right place! This article will cover everything you need to know about this excellent packaging option to ensure you have all the information required to make this important decision.

- 1. What is flexible packaging, and why is it better?

- 2. When designing your flexible package, there are a few important things to take into account

- 3. Selecting the Right Packaging Materials

- 4. Graphic design and printing techniques

- 5. Flexible packaging: safety, compliance and quality

- 6. Industry Insight: The Nestlé Sustainable Initiative of Flexible Packages

- 7. Prospects for the flexible packaging market

1. What is flexible packaging, and why is it better?

It is important to have a general understanding before delving into the numerous details that make this packaging option so great. Therefore, the first question that should always be asked is: what is it?

As the name implies, flexible packaging is a flexible solution created using pliable materials such as plastics, paper, films and foils, or a combination of these. Any packaging that transforms when filled or used is popular with businesses and consumers due to its light weight, cost-effectiveness, low carbon footprint, increased product shelf life and infinite customisation potential.

Compared to other forms of traditional packaging, such as rigid boxes, flexible packaging is lighter and cheaper. The films and materials used to create these flexible materials consume fewer resources and energy to produce, providing a cheaper method of shipping, warehousing and logistics. Businesses have the chance to save money throughout the whole supply chain, while maintaining high quality. However, this is not the only advantage.

Reduced resources and energy consumption saves money and reduces greenhouse gas emissions compared to traditional packaging. The effective utilisation of materials, even in the disposal process, leads to a reduction in the total amount of waste that goes to landfills, minimising the negative environmental impact of this type of packaging and representing a significant step towards sustainability and reducing the carbon footprint.

Flexibles says that flexible packaging provides a longer shelf life and a higher level of protection against contaminants, such as oxygen, moisture, light and microorganisms, which can lead to oxidation, spoilage, discolouration and contamination. This enhanced protection improves the shelf life of products and minimises product waste caused by spoilage.

Lastly, there are unlimited customisation and branding possibilities. You can choose from a wide variety of options, including colour selection, eye-catching graphics, the inclusion of your logo and brand messages, and the type of package you want, such as spouted, flat or stand-up pouches. With such customisation options, you can design packaging that protects your products and acts as a powerful marketing tool to create a lasting impression on consumers.

2. When designing your flexible package, there are a few important things to take into account

Now that you are aware of the advantages of flexible packaging, do you think you will use this type of packaging solution for your products? If so, we will take a closer look at the main considerations to bear in mind when planning.

In order to design effective and successful packaging, it is important to pay attention to a number of critical factors. The first thing that both your product and the consumer will notice is the packaging, so it is important to design a package that will attract attention and convey the value of your brand. Colour, typography and graphics are some of the elements that help to convey your intended message and appeal to the target audience.

Knowing the needs of your product is also important in order to choose the right packaging materials and formats. Shelf life, product freshness and transportation are important factors that should not be ignored, and neither should sustainability. In the current market, the integration of sustainability and environmental practices is taking on a new dimension, with more customers demanding environmentally friendly companies. Although numerous important factors must be considered, such as those listed above, you do not have to do it alone.

It is strongly advisable to consult experts in packaging design and manufacturing, since they have the necessary experience and industry knowledge to help you make the right decisions regarding materials, structure, and ease of use. You can also look to consumers for guidance. By analysing consumer behaviour, conducting surveys and monitoring market trends, brands can gain insight into consumer preferences, which can guide packaging designers in making informed decisions regarding the visual appeal, functionality and features of the packaging.

Achieving effective packaging design requires a team effort to strike the right balance between aesthetics, functionality and sustainability, resulting in a memorable and impactful solution. This has never been easier to achieve than with flexible packaging.

Flexible packaging is practical and versatile, offering a better user experience and adding value to your product thanks to its reusability, convenience and sustainability. Its flexible nature enables creative design features that impress potential buyers, such as innovative shapes, colours, and textures that make products unique on the shelf.

Flexible packaging offers plenty of space for creative use of graphics, logos and brand messages, which are essential for product differentiation in a competitive market. The packaging design should reflect your brand identity and create a strong visual association with consumers.

However, when experimenting with all these creative branding and customisation choices, it is important to remember that structure, protection and functionality are also vital factors.

The package must focus on product security, but also be convenient, keeping the product fresh and intact while appealing to the user-friendly experience everyone desires. This can be achieved by carefully choosing the right materials and taking into account factors such as barrier properties, puncture resistance, and shelf life. It is important to balance convenience and protection in the design of your packaging to satisfy consumer expectations and stand out from the competition.

So, what should you use to strike this balance? Professional packaging designers and manufacturers can help you identify the most suitable material for your product. However, we will discuss some common flexible packaging materials to give you a better idea of what is available.

3. Selecting the Right Packaging Materials

The material used plays an important role in determining the performance and suitability of any packaging solution, particularly in the case of flexible packaging. Product compatibility, barrier properties and sustainability are some of the key factors that help determine the right materials to complement and improve your product.

When it comes to flexible packaging materials, a number of alternatives have become popular due to their performance and versatility across various industries.

- Bio-plastics, such as biodegradable plastics and plant-based bottles, are effective at keeping air, grease, and oils out of products, and are therefore used in flexible plastic packaging in the food and snack industry.

- Polymer films, especially plastic films, dominate the market because of their flexibility and durability, and they are very common in the food industry.

- Although it cannot be classified as flexible packaging, corrugated cardboard provides moisture and damage protection, as well as acting as an effective cushion during transportation.

- Aluminium foil is an effective shield against oils, moisture and light, and can be moulded into different shapes, such as trays and lids.

- Kraft paper is strong and elastic and is usually used to package chemicals, food and durable consumer goods.

- UV protective films maintain product quality by blocking harmful UV radiation to prevent damage, and are used in the food industry for storing and transporting products.

While the above materials are all popular and excellent options for flexible packaging, we will also consider a few alternative materials in line with eco-friendly objectives as part of a move towards greater sustainability.

Brands that want to be environmentally friendly can use fewer materials or Post-Consumer Recycled (PCR) materials. Another option is to use renewable materials, such as plant-based resins and paper, which provide a more environmentally friendly alternative to plastic. They can also be filled with polylactic acid (PLA) film, which is industrially compostable.

Making sustainable material choices plays a key role in reducing environmental impact, so take note! Failing to consider all the possible materials for your packaging, including sustainable alternatives, will restrict you, especially as more consumers are demanding that companies implement eco-friendly initiatives.

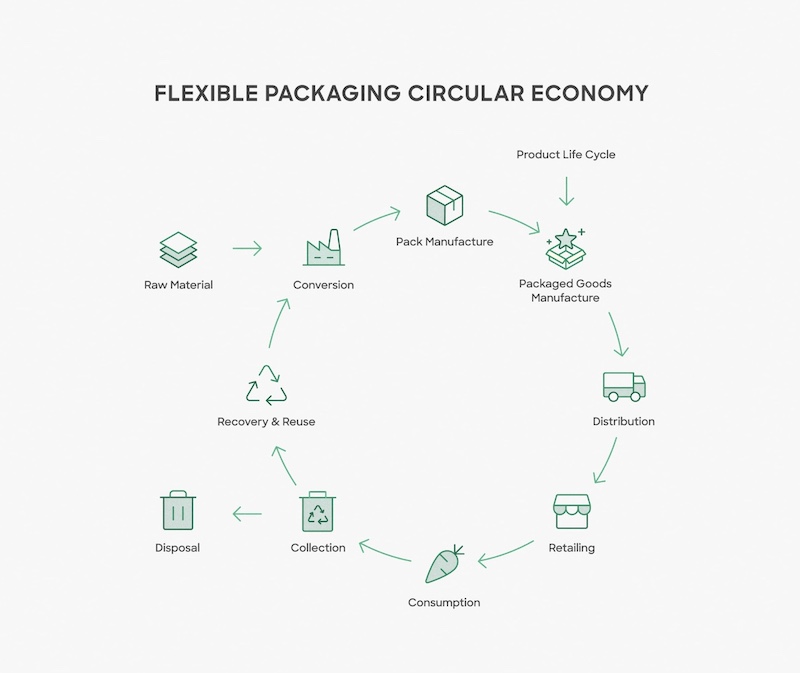

A sustainable economy is essential to eco-consciousness because it reduces waste and maximises resource utilisation throughout the product lifecycle. Unlike the conventional linear economic model, the circular economy aims to minimise waste and pollution by making use of renewable energy and resources, facilitating material flow and recycling, and aligning supply chains with nature-oriented values.

Such practices are especially important in the case of flexible packaging, as they ensure a minimum environmental impact. Flexible packaging is an integral component of the circular economy, as it utilises fewer raw materials, can be easily recycled and reused, and is compostable, enabling it to break down into biodegradable packaging. By adopting the circular economy, companies can significantly reduce the carbon footprint of their packaging and help create a more sustainable future.

4. Graphic design and printing techniques

Now that you have a clearer idea of the variety of materials available to you, both popular and sustainable, it is time to explore the potential printing methods and graphic designs you can use with them.

With so many types of materials and flexible packaging, such as stand-up pouches, you will be glad to know that there are many printing options too! You can choose from several printing and curing technologies to add colours, text, and graphics to your packaging design.

- Flexography is a common process for printing on flexible materials that produces high-quality results with vivid colours. It can print complex designs and patterns on other flexible materials.

- Digital printing offers accurate, detailed graphics and customisable features. It enables brands to produce bright, attractive packaging that is cost-effective for small print runs.

- Rotogravure printing is characterised by its high-quality image reproduction and is ideal for applications where rich, detailed graphics are required.

By using this superior printing method alongside high-quality images, fonts and colours that match your product and brand image, you can produce attractive designs that effectively deliver your brand's message and appeal to your target audience.

5. Flexible packaging: safety, compliance and quality

Now that you have finalised the design, materials and printing techniques for your packaging, what is next? The second step is to comply with industry standards and regulations for this type of packaging. Flexible packaging quality control involves a series of tests and procedures to ensure its integrity and functionality. These tests include:

- The Pressure Decay Test determines the package's capacity to withstand pressure, identifying any leakages or defects.

- The Instron test determines the seal strength of the packaging, which must be able to withstand the turbulence of handling and transportation without losing its integrity.

- The Bell Jar Test measures the barrier properties of the packaging materials to establish how well they can protect the contents against external elements such as moisture and oxygen.

Quality control processes provide valuable insights to manufacturers regarding the quality and performance of flexible packaging. Through such tests, manufacturers can detect any weaknesses or shortcomings in the design or materials and make the necessary adjustments and improvements. Compliance with accepted industry standards also guarantees that the package will meet the necessary specifications and provide consistent performance.

Quality control is not restricted to controlled environments. The global supply chain faces growing challenges regarding product safety. The number of food recalls has increased, with microbial contamination and unsanitary handling playing a major role. The entire supply chain must undergo rigorous testing to protect consumers and reduce health hazards.

Regulations and certifications are essential to guarantee the health and safety of consumers by ensuring high standards of material safety, hygiene, and product quality. Certifications such as FDA, CFIA and EU compliance demonstrate compliance with certain regulatory standards, enabling brands to guarantee their products to consumers, thereby instilling confidence and becoming part of responsible and ethical packaging.

6. Industry Insight: The Nestlé Sustainable Initiative of Flexible Packages

If you are still unsure about using flexible packaging as a safer, more convenient and sustainable alternative to traditional packaging, consider the example of Nestlé, a large corporation that is actively implementing this kind of packaging.

Nestlé has adopted an all-encompassing sustainability programme that incorporates flexible packaging. The programme is based on three principles: better packaging, less packaging and better systems.

To improve its packaging, Nestlé is minimising its use of virgin plastic by actively searching for alternatives and finding new solutions to the problem. This involves piloting reuse and refill systems, maximising the use of paper and flexible packaging, and helping to develop efficient collection, sorting and recycling systems in countries where the company operates.

To develop superior waste management systems, Nestlé partners with companies around the world to overcome infrastructure challenges related to waste collection, sorting and recycling. Nestlé aims to set an example with effective collection schemes and encourage the creation of working systems through joint projects and activities.

Through its commitment to sustainable packaging practices, Nestlé is actively involved in the shift to a circular economy, in which resources are used efficiently, waste is reduced, and environmental sustainability is prioritised.

7. Prospects for the flexible packaging market

Flexible packaging is a relatively new concept. However, it is constantly evolving and improving, and this alternative to conventional packaging is advancing all the time.

Smart packaging innovations are starting to converge with flexible packaging. Sophisticated sensors and indicators can now be used to monitor product condition, ensuring freshness and safety throughout the supply chain by detecting spoilage and preventing harmful substances from entering the package. With the introduction of QR codes, RFID tags and NFC, consumers are provided with essential information that prevents theft and counterfeiting. Smart packaging solutions designed specifically for flexible packaging increase product quality, provide consumers with more information, make brands more relevant and make food safer.

Flexible packaging is quickly becoming popular due to its convenience, light weight and positive environmental impact. This is further improved when coupled with intelligent packaging and its innovative technologies. This type of packaging will not just be an alternative in the near future. Its adaptability and ability to meet consumer needs in terms of sustainability and ease of use will make it the norm in most industries.

If you are interested in flexible packaging solutions, talk to one of our product specialists to receive professional guidance on the best solution for you!

About Printing Craftsmanship

What is embossing, and how is it different from debossing?

Embossing is a technique that creates a raised impression on a material, while debossing presses the design inward, creating a recessed effect. Both techniques add texture and sophistication to printed materials.

Special Shape Boxes

Can I print on the inside of the box?

Yes, you can print any effect you want on the inside.

About Us

What is the minimum order quantity for packaging?

1000 units. The MOQ is based on every unique box (e.g. size, design).

Rigid Magetic Boxes

Can I order a sample of my packaging box?

Yes, we strongly recommend that you do so, we provide a variety of sample types to meet different usage situations and help you guarantee the best results!

How long does it usually take from design confirmation to delivery?

The lead time is usually 15-25 days, depending on the production of the order

Start Your Packaging Journey Today

Discover Our Curated Collection of Bespoke Packaging Cases & Tailored System Solutions

© 2025 WINPACK PRINTING. All rights reserved

Wenhua Printing packaging

winpackprinting

Winpack Printing