What is Glittering in Packaging?

In the highly competitive modern retail world, packaging is no longer just a container; it is a brand statement. Of the many visual tools employed to attract consumers' attention, glittering packaging has become one of the most effective ways to convey luxury, excitement and high-quality value.

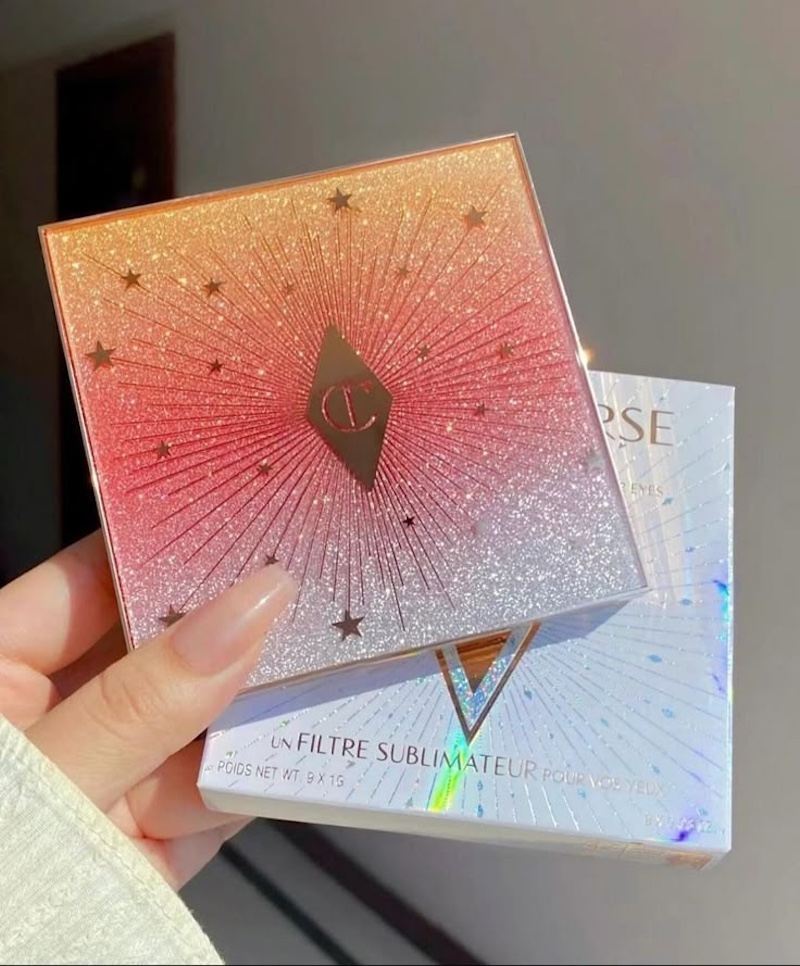

Glittering effects can transform ordinary paper packaging into a sensory and emotional experience, as seen with glittering cosmetic boxes and gift wrapping. But what exactly is glittering in packaging? How is it achieved? Which materials and printing methods are used, and when should brands use them?

This paper provides an in-depth reference to glittering in packaging, including its definition, manufacturing techniques, choice of materials, usage, advantages and future trends, to help brands and consumers make the right choices.

- What Is Glittering In Packaging?

- Glittering Techniques

- Dry Sprinkle Adhesion Process

- Ink Formulation Method

- Uses In Other Types Of Packaging

- Rigid Boxes

- Corrugated Boxes

- Paper Hang Tags

- Methods of Successful Glittering

- Design Considerations

- Application Tips

- Ink Formulation Method

- Future Trends in Glittering

- Technological Innovations

- Market Trends

- Conclusion

What Is Glittering In Packaging?

Glittering in packaging is a visual effect that produces sparkle, shine, or reflective brilliance on packaging surfaces. These effects are intended to attract attention, capture light, and increase the perceived value of a product.

Unlike normal glossy finishes, glittering effects usually include:

- Light-reflective particles

- Metallic or holographic material;

- Special surface treatment or printing methods are also used.

They are not only shiny, but also create dynamic visual movement and a surface that varies with changes in light and viewing angle.

Glittering Techniques

Dry Sprinkle Adhesion Process

Process and Materials Used

This printing technique involves applying an adhesive ink layer to the areas of your packaging that you want to print on. After laying the adhesive layer, sprinkle the crystalline glitter materials onto it. Finally, the printed material is dried to fix the glitter.

Benefits and Costs

The result is an impressive, rough glitter effect that really stands out. However, it has its downsides. The glitter particles easily become airborne, which may cause contamination. This makes it unsuitable for large-scale production.

Ideal Applications

Use the dry sprinkle adhesion technique for special editions or high-end product lines where a bold, glittering effect is required. It is also ideal for small-scale production or high-end products that require an added touch of sophistication.

Ink Formulation Method

Process and Materials Used

In the ink formulation process, crystalline glitter particles are combined with a binder to form an ink. This glitter ink is then applied to the packaging using standard printing methods.

Benefits and Costs

This process is less contaminated and more suitable for mass production. It provides a uniform glitter effect, eliminating the clutter of loose particles. However, the sparkle is less pronounced than with the dry sprinkle technique, since the glitter particles must be smaller to print smoothly.

Ideal Applications

The ink formulation technique is best suited to large-scale production batches where uniformity and purity are paramount. It is an excellent option for everyday consumer items that benefit from a subtle glittering touch without the need for excessive sparkle.

Uses In Other Types Of Packaging

Rigid Boxes

Use rigid boxes for your luxury, high-end product packaging. The glittering finish gives an instant feeling of exclusivity and sophistication. Whether you are wrapping jewellery, electronics or high-end spirits, a touch of sparkle will make the unboxing experience special and memorable for your product.

Folding boxes are ideal for cosmetics, personal care products and a broad spectrum of other consumer products. Adding glitter to these boxes makes them more eye-catching and therefore more visible among the many boxes on retail shelves. Think of a glittering eyeshadow palette or a glamorous perfume box – these are the things that catch the eye and prompt purchases.

Custom printed paper bags are also an important branding tool for retailers. By adding glitter to these bags, you are turning them into walking advertisements for your store. Glittering your bags will make them more appealing and encourage repeat use, increasing brand awareness.

Corrugated Boxes

First impressions are important in e-commerce and subscription boxes. Glittering corrugated boxes bring excitement to the unboxing process. When customers open a sparkling box, it creates a positive association with your product, increasing satisfaction and loyalty.

Paper Hang Tags

In the apparel and fashion industry, details matter. Glittering paper hang tags can add a touch of sophistication and style. Such labels make your clothes or accessories look more expensive. This small detail can significantly impact the perceived value of your products.

Strategically using glitter on these types of packaging can make your product much more attractive and leave a lasting impression on your customers.

Methods of Successful Glittering

Design Considerations

When adding glitter to your packaging design, it is important to select the most appropriate areas to ensure the best effect. Consider which elements could benefit from a touch of sparkle, such as logos, brand names, or specific design accents. This tactical approach ensures that the glitter enhances the design without overwhelming it.

Balance is key. Glitter can make your packaging stand out, but too much can make it less readable and coherent. Use glitter sparingly to emphasise key points and ensure your message is clear and visually appealing. The aim is to impress your audience without sacrificing legibility.

Application Tips

The use of glitter should be clearly explained, and best practice should be followed. No matter what technique you use, whether it's the dry sprinkle technique or the ink formulation, here are some key tips to help you achieve a high-quality finish:

Dry Sprinkle Adhesion Process

- Use a uniform amount of adhesive ink on the areas.

- Ensure the glitter is spread uniformly over the adhesive and then left to dry.

- Reduce the dispersion and contamination of particles by using fine mesh screens or controlled environments.

Ink Formulation Method

- Combine the glitter particles with the binder to form a homogeneous ink.

- Test on a sample material to ensure it glimmers well and the ink is applied smoothly.

- Use accurate printing methods to ensure clean edges and prevent smudging.

The most important thing is durability, whatever the method. Ensure that the glitter sticks to the packaging material to withstand handling and transportation. This includes adequate curing times and, where applicable, extra protective finishes to secure the glitter.

By bearing in mind these design considerations and application tips, you can achieve a beautiful, glittering effect without compromising the quality or readability of your packaging.

Future Trends in Glittering

Technological Innovations

The future of glittering in packaging looks bright, thanks to new techniques and materials. Digital printing technology enables glitter to be used in a more precise and consistent way. These innovations enable more complex designs and custom glitter effects based on the needs of a particular brand.

New materials are also on the horizon. Non-toxic, biodegradable glitter is becoming increasingly popular as it does not affect the visual effect and is therefore not an environmental issue. Additionally, intelligent glittering, incorporating interactive features such as augmented reality, will transform the consumer experience with packaging.

Market Trends

A number of market trends will dominate the glitter landscape in the future. Sustainability will remain a driving force. As customers become more environmentally aware, brands that embrace sustainable glittering will probably gain a competitive advantage. This involves using biodegradable glitter and reducing environmental impact in the production process.

Another trend to watch is personalisation. Glitter effects that can be customised to suit individual consumers' interests will boost brand loyalty and sales. We can expect to see more brands offering limited-edition glittering designs that appeal to a certain occasion or target customer.

Conclusion

Glittering packaging is about more than just aesthetics—it's a powerful tool for brand differentiation and consumer engagement. Strategically applying glitter can elevate your packaging, making it stand out on crowded shelves. The two main techniques, dry sprinkle adhesion and ink formulation, offer different advantages and applications. As technology advances, new materials and methods are making glittering more sustainable and versatile. Understanding these techniques and their advantages can help you create packaging that attracts attention and communicates quality and luxury.

Contact us today to discuss your custom glittering packaging requirements. Our team of experts is ready to help you design and implement solutions that perfectly match your brand's identity.

Special Shape Boxes

Can I print on the inside of the box?

Yes, you can print any effect you want on the inside.

OEM Services

Do you offer eco-friendly and sustainable packaging options?

Yes! We provide environmentally friendly packaging solutions, including recyclable, biodegradable, and FSC-certified paper materials. Let us know if you’re looking for sustainable options.

About Us

How long does shipping take?

Air freight options range from 7-21 days, while ocean freight options range from 26-71 days. If you need some units expedited earlier, consider splitting your shipment between air and ocean!

About Printing Craftsmanship

What are the different types of printing techniques?

There are various printing techniques used for different purposes, including:

Offset Printing – Ideal for high-volume commercial printing, offering sharp and high-quality images.

Digital Printing – Suitable for short-run printing with fast turnaround times.

Screen Printing – Used for printing on textiles, plastics, and other materials with thick ink layers.

Hot Stamping – Adds metallic or pigmented foil using heat and pressure for a luxurious look.

Embossing & Debossing – Creates raised or recessed designs for a textured effect.

UV Printing – Uses ultraviolet light to instantly dry ink, offering vibrant colors and enhanced durability.

Rigid Magetic Boxes

Can I get a sample before placing an official order?

Yes, we provide samples to our customers. Please contact our sales team to inquire about sample availability and pricing.

Start Your Packaging Journey Today

Discover Our Curated Collection of Bespoke Packaging Cases & Tailored System Solutions

© 2025 WINPACK PRINTING. All rights reserved

Wenhua Printing packaging

winpackprinting

Winpack Printing