Folding Carton Box Packaging – The Master Guide

Have you considered using a folding carton to package your product? If so, you've come to the right place to find out everything you need to know about this option! These foldable paper boxes are a fashionable and adaptable packaging solution for many industries. Although these boxes are usually used for packaging food, they can also be used for pharmaceuticals, cosmetics, and electronics.

Paperboard is ideal for creating packages of any size, shape or structure to suit your product.

In this article, we will explore folding cartons in depth, beginning with a definition and moving on to the materials commonly used, styles, the manufacturing process and the advantages and disadvantages of this type of packaging. By the end of this comprehensive guide, we hope to have provided you with sufficient information to help you decide whether this paper carton packaging alternative is suitable for your product.

So, what is a folding carton?

Before we take a closer look at this versatile packaging option, let's find out what it is. Folding cartons are a type of paperboard packaging used for consumer products due to their light weight and flexibility.

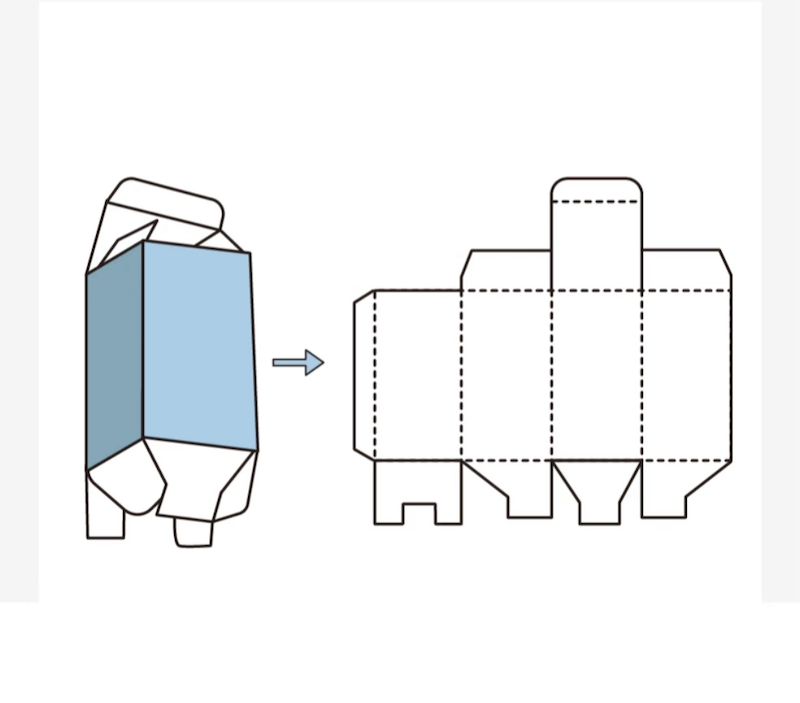

They are often used for secondary packaging, and as the name implies, these foldable paper boxes are designed to be assembled from a single flat sheet into a three-dimensional package. This makes them cheap to store, as they are shipped flat, and they can be customised to a high degree.

Folding cartons vs rigid vs corrugated

But what are the differences between these similar, equally popular types of packaging? To gain a clearer insight into the main differences between each option, we have created a basic chart below.

| Rigid Boxes | Folded Carton Boxes | Corrugated Boxes | ||

|---|---|---|---|---|

| Set up | None if not foldable | Needed | Needed | |

| Sturdiness | High | Low | High | |

| Product Safety | High | High with the aid of inserts | High | |

| Cost | Generally High | Depends on printing & finish | Depends on printing & finish | |

| Appeal | Generally High | Depends on printing & finish | Depends on printing & finish | |

| Reusable | Yes | Usually not |

Types and styles of folding carton packaging materials

The most popular materials used in the production of standard folding cartons are paperboards made from wood pulp, a renewable and eco-friendly resource. However, there are more advanced, certified paperboards that can be used for food and medical applications.

To make it even more eco-friendly, kraft paperboard made from 100% post-consumer recycled material or reclaimed paper stock is also a popular choice. And if you thought the range of materials was extensive, there is also a wide variety of styles and types of box. In this master guide, we present the seven most popular styles.

The crash bottom box, also known as the tuck end auto-lock bottom box, has a bottom that automatically locks into place with a simple tuck flap. This box is ideal for heavy products such as wine and beer because it is the most robust of all the paper box packaging listed below.

Another option is the snap bottom or lock bottom box, which is also strong and can be used to store heavy products such as wine or electronics. This style of box is also referred to as the '1-2-3' bottom box because the flaps are pushed inwards and clamped.

Straight tuck end boxes are flat-packed and do not require assembly. They are characterised by the top and bottom closures being on the same side of the box, with slits in the ends to hold the tucks in place. This style is best suited to light or medium-weight products, such as cosmetics or essential oils.

Reverse tuck end boxes are identical to straight tuck end boxes, except the end closures are on the opposite side of the box. Reverse tuck boxes are also suitable for light- or medium-weight products, as they are almost identical.

Paper sleeve packaging is a type of carton designed to slide over a plain box. It is a highly popular option because it is the cheapest and can instantly customise a plain box.

Two-piece boxes, also known as double-wall tray-and-lid boxes, are divided into a top and bottom half. The tray and lid fit together perfectly to form a robust double wall, making them ideal for packaging luxury products such as jewellery and clothing, or for use as food packaging for products such as confectionery.

The latest trend is customised folding carton boxes. Who said foldable cartons had to be like that? The above options have custom cut-outs and inserts, the possibilities for which are limited only by the imagination. Inserts or cut-outs can be placed in strategic spots to give your packaging a special flair that sets it apart from competitors' packaging!

The styling possibilities are endless, whether you choose paper food packaging with folding cartons or packaging for other products, such as cosmetics and electronics. Whether you choose kraft paper packaging because it is environmentally friendly or a two-piece box to add luxury, these foldable paper boxes are a great choice for any product!

Manufacturing processes

No matter what materials or style you want to use for your carton packaging project, the process of creating folding cartons remains the same. Once you have finalised the design of your box, it is time to leave your packaging supplier to work through the following detailed processes, collectively known as 'converting'.

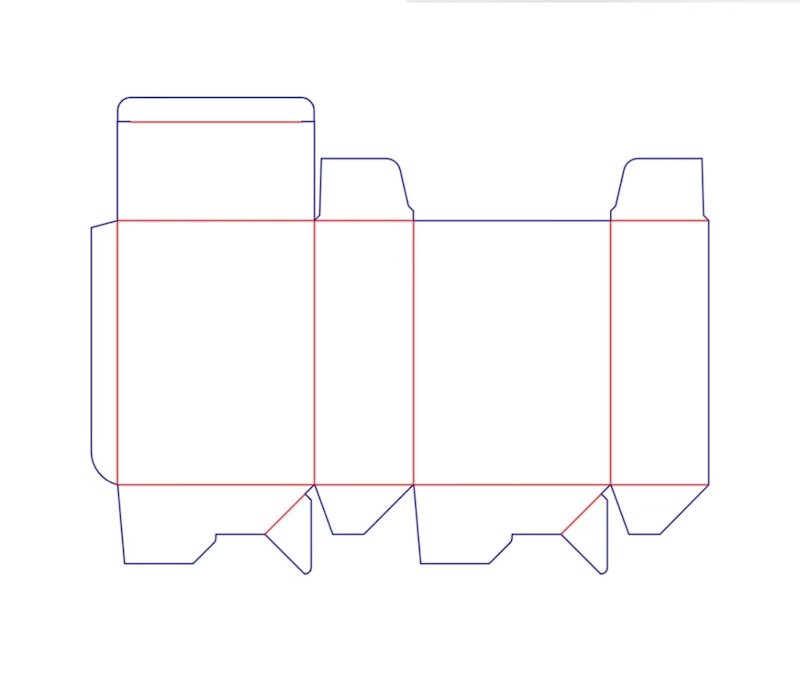

1.Die lines and sheet layout: Die-lines are two-dimensional representations of the box, showing what the final 3D box will look like. They show where the die-cutting, folding and gluing will occur, as well as the position of the artwork on the finished package.

2.Sheeting and printing: Paperboard is cut into large rolls, which are then cut into sheets and subjected to the printing press. At this stage, manufacturers ensure that the grain runs in the most efficient and effective direction. Once the sheet goes to the printing press, the imagery and artwork you designed will be inked and applied to the sheet using offset, digital or flexographic printing techniques.

3.Post-press finishes: Additional customisation options, such as hot-foil stamping, embossing or debossing, can be performed on specialised equipment at this stage to enhance the appearance of your box.

4.Die-cutting: Numerous duplicates of your carton are cut out of the paperboard sheet at this stage. The die is a specialised cutter, similar to a cookie cutter, which cuts the paperboard with minimal waste and allows for easy folding where required. The manufacturer recycles the surplus paper scraps produced at this stage into new paperboards.

5.Folding and gluing: This is the final step in the conversion process, during which your box is fed through a machine that folds, pre-breaks and glues the flat, die-cut pieces. Certain cartons featuring transparent windows are incorporated at this stage. The manufacturer will strive to complete these processes in as few passes as possible.

Pros and cons of folding cartons

Having discussed what constitutes an excellent and popular folding carton packaging option, what are the advantages and disadvantages of this solution? As with other popular alternatives, there are pros and cons. These are some of the factors that should be considered when choosing the best packaging.

Firstly, this type of packaging can be affordable, environmentally friendly and reusable. Carton boxes can be made in various shapes and sizes, and are inexpensive to produce in bulk. The materials employed in the manufacturing process are also 100 percent recyclable and therefore better for the environment.

There are also numerous printing and special finishing options available for folding cartons. As stated in this guide, printing can be done using offset, digital or flexographic methods to achieve excellent colours, special textures and visual effects. This type of packaging will provide special finishes such as:

- Glitter/pigment sprinkles

Even certified grades of paperboard material are available to meet the needs of the food and medical industries.

However, despite the many advantages of folding cartons, there are a few disadvantages compared to other alternatives. Power and longevity may be a drawback, but foldable cartons can be made hard and strong with extra inserts. However, they are not as protective of the product inside as more rigid and corrugated boxes are.

Also, the thickness is restricted to 0.81 mm due to the cutting machinery, so it is difficult to imagine this type of packaging accommodating very heavy products.

Although we did say that folding cartons are sustainable, some of the packages are difficult to assemble and are often disposed of improperly after a single use. This adds to waste and undermines the environmental friendliness of this option.

Overall, this is a great packaging option for most products, but it is always good to weigh up the pros and cons to ensure it is the right choice. So, which industries are these foldable boxes most suitable for?

Appropriate to many, optimal to a few

The food and medical industries are the first that come to mind when thinking of industries that would best fit foldable cartons. As previously mentioned, this type of packaging comes in various grades of paperboard that meet industry standards, which is where the benefit lies.

However, there is no doubt why medical and food companies choose folding cartons when there are more expensive and more durable grades of paperboard, such as Solid Bleached Sulphate (SBS) and Folding Box Board (FBB). Different grades of paper can also be used to ensure that sensitive products are not damaged by dust and to preserve them for longer.

Other industries that can benefit greatly from foldable box cartons are the cosmetics industry, with its lightweight and appealing box carton designs, and the electronics industry, which requires protection from physical damage, dust and moisture.

However, even though these industries benefit most from this packaging option, this does not mean that folding cartons cannot be used to package products in other industries. Other industries that can benefit from foldable box cartons are the cosmetics industry, due to its lightweight and appealing packaging designs, and the electronics industry, due to their ability to withstand physical damage, dust and moisture.

While these industries benefit the most from this type of packaging, this does not mean that folding cartons cannot be used for other products outside these industries.

So let's get packing!

Even if your product is not in the above industries, folding cartons can still be very helpful. If you're still not sure whether this type of packaging is right for you or if you're ready to take the next step in your packaging project, call one of our packaging experts to find out more!

About Us

Are you a manufacturer?

Yes, we are manufacturer, and we have over decade experience in this field.

What is the minimum order quantity for packaging?

1000 units. The MOQ is based on every unique box (e.g. size, design).

Rigid Lift-off Box

Can I order a sample of my rigid box?

Yes, we strongly recommend that you do so, we provide a variety of sample types to meet different usage situations and help you guarantee the best results!

Special Shape Boxes

Can I order a sample of my packaging box?

Yes, we strongly recommend that you do so, we provide a variety of sample types to meet different usage situations and help you guarantee the best results!

Rigid Magetic Boxes

Can I get a sample before placing an official order?

Yes, we provide samples to our customers. Please contact our sales team to inquire about sample availability and pricing.

Start Your Packaging Journey Today

Discover Our Curated Collection of Bespoke Packaging Cases & Tailored System Solutions

© 2025 WINPACK PRINTING. All rights reserved

Wenhua Printing packaging

winpackprinting

Winpack Printing