Edible Packaging – The Fast Approaching Sustainable Packaging Trend

Using plastic in the food industry is nothing new, and the issue of environmental degradation has become a global concern. As we become more informed about the necessity of sustainability and the numerous efforts being made to reduce our reliance on plastic, we should consider the many alternative options and innovations that are becoming increasingly accessible as technology develops.

One such option is edible packaging, which has become increasingly popular in recent years due to the obvious paradigm shift towards eco-friendliness. Governments, packaging experts and businesses are already investing more money in this alternative, creating a rapidly growing market ready to be exploited.

As suppliers continue to develop consumable solutions, this new packaging movement will only continue to grow.Now is the right time to explore this market, and we will provide all the necessary information to help you get started. We will discuss the various types of edible packaging currently on the market, as well as some of the pros and cons, so you can decide for yourself whether it's the right choice! However, before we can delve into the details of this wonderful alternative, we must first discuss the basics.

1. What is edible packaging?

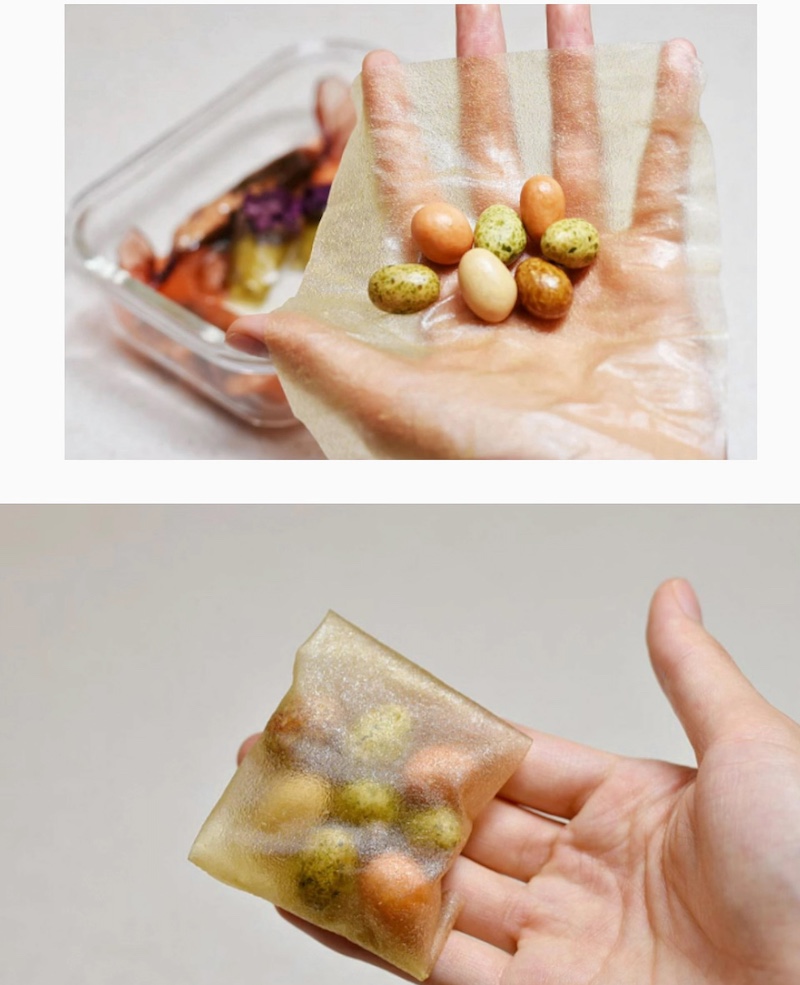

As the name suggests, it is a sustainable form of food packaging that is designed to be consumed or biodegraded as effectively as the food it protects. Edible packaging is often made from natural, plant-based substances such as seaweed or casein. Any kind of film, sheet, layer or coating can be considered edible, provided it can be consumed with the food item.

Since the package is eaten rather than discarded, this green packaging method is ideal for helping us to reduce our reliance on plastics and produce less waste, as nothing is left behind.

This is a timely solution for the food industry, which has recently come under scrutiny due to the sheer volume of waste it generates. Most conventional food packaging is made of non-biodegradable, non-natural materials. According to statistics from the United States Environmental Protection Agency, food and plastic constituted over 30 per cent of solid waste in 2018.

Fortunately, different types of consumable food packaging can be made from bio-materials and plant by-products, providing an environmentally friendly alternative to traditional packaging. Now that you know what edible packaging is and how it helps reduce waste in the food industry, you might be interested in the types available.

2. Edible packaging options

Although consumable packages are a more recent addition to the range of sustainable options, you will probably already have come across them and will certainly see more variations in the near future. One example of edible packaging is ice cream waffle cones. With more and more innovations coming to market, there are more choices on the horizon.

Examples of companies trying out new packaging methods include hard cookie coffee cups, sweet gelatin packaging, fruit-shaped casings and candy wrappers made of potato fibres or rice paper.

Other popular innovations include:

Straws: Eatable straws, such as those presented here, are a fashionable product designed to reduce the use of traditional drinking straws. They are made from tasteless pasta of wheat and water, apple fibres or sweet sugar, and can be used with any beverage, whether fizzy, fruity or alcoholic.

These straws take almost an hour to dissolve, and can be eaten as a snack while you drink. Alternatively, if you prefer a less invasive experience, pasta straws are tasteless and can even be used for hot beverages! All straws are either edible or 100 per cent biodegradable.

Food film: More recent. Researchers at the University of Nottingham have created an edible, 100 per cent biodegradable food film made from plant-based carbohydrates, including konjac flour, starch, cellulose and proteins. This new food packaging film improves storage, safety and shelf life, and is far more environmentally friendly than plastic.

Eco-bags: Avani is an Indonesian company that has created a biodegradable eco-bag made from cassava root. This bag can be dissolved in warm water and is safe for human consumption, although it is not intended to be eaten. Avani's eco bag feeds fish and insects rather than poisoning them with plastics!

Spoons: Bakeys has developed the world's first line of consumable cutlery made from rice flour, wheat and sorghum, in an effort to combat plastic pollution. The company intends to produce environmentally friendly, vegan eating utensils that are free from trans fats and preservatives and can be used by large numbers of people. Cutlery contributes to environmental destruction caused by the food industry in the United States alone, which uses more than 40 billion plastic utensils every year. Bakeys aims to reduce this impact.

Bottles: Ooho is the most popular edible substitute for plastic bottles. Created by Skipping Rocks Lab, Ooho is made using a culinary technique known as spherification. Skipping Rocks Lab created a transparent gel wall using a double membrane of sodium alginate and calcium chloride that is solid enough to support liquid in a spherical pouch. This fully edible container does not leave any waste, unlike a normal plastic water bottle.

3. How is edible packaging made?

As demonstrated in the section above, consumable packaging is available in a wide variety. This form of sustainable packaging is a relatively recent innovation, so experimentation and constant innovation are ongoing. There is no single way of making edible packaging. Nonetheless, there are a number of rules that packaging innovators should adhere to, to ensure their invention is as unobtrusive as possible to the consumer experience and is actually more eco-friendly than conventional methods.

The ultimate purpose of packaging is to protect and preserve the product. As most common edible packaging materials have shortcomings, packaging is often developed using multiple materials to counterbalance each other's weaknesses.

Secondly, to avoid adverse environmental effects when consumed or biodegraded, synthetic, toxic substances such as plastics should be avoided! Natural materials to consider include wheat, seaweed, alginate, fruit or plant fibres in a complementary combination.

Once the right materials have been chosen, films and coatings are formed by emulsifying or dispersing film-forming polymers in a solvent such as water or ethanol. The mixture is then sprayed onto the food item with the help of the solvent.

Lastly, while a significant proportion of consumable packaging on the market may have complementary flavours, the packaging must generally be neutral or tasteless. This is because if the taste is too strong, there is a risk that the product inside will absorb the flavour and spoil. To prevent this, you should always consider using tasteless or mild flavours with your product.

4. Here are some reasons why you should consider edible packaging for your business.

Now that we have a better grasp of this new form of sustainable packaging and the vast amount of innovation that has gone into its creation, you may be wondering what advantages there are to entering the edible packaging market. The advantages are similar to those of other sustainable packaging options.

--Meet customer expectations

The most important business issue is the ability to meet customer expectations regarding sustainability. The world has become more eco-friendly, and customers are becoming more critical of brands to ensure that sustainability is a core practice.

One of the most effective ways to achieve this is through edible packaging.

Since this kind of packaging produces zero waste and is natural and biodegradable, it is an excellent way to demonstrate your company's long-term commitment to the environment and create a loyal customer base.

--Diverse purposes

There are numerous ways to customise this packaging and make it stand out, since there are many innovations in creating new methods of using consumable packaging. This sustainable packaging is multipurpose and can serve a variety of purposes in terms of sustainability, versatility, and cost savings.

Examples of this diversity include single-use products such as the ice cream waffle cone discussed in the previous section of this paper, as well as refrigerated packaging. The scope of usage is extending even further with technological developments in hot liquid containers and food preservation!

--Being a better human to the planet.

Finally, edible packaging is an excellent way to help save the planet. It is one of the best options for sustainability. By removing the normal waste cycle and avoiding recycling processes, no traces are left to end up in landfills or be disposed of inappropriately. Even if consumer behaviours lead to improper disposal or littering, 100% biodegradability guarantees a safe and happy planet.

5. Disadvantages of edible food packaging.

However, as with any other sustainable packaging, there are still drawbacks. This form of packaging has yet to be refined, and currently it may still require non-consumable materials, which cancels out some of the environmental benefits.

Furthermore, as edible packaging is more susceptible to temperature and heat, extra care is required during shipping, which may be too costly for some businesses to maintain.

Although a lot of research has indicated that edible food packaging is safe and effective, it may be challenging to win customers' confidence in it. It will take time for the culture of consumable packaging to be adopted because people are accustomed to disposing of packaging and viewing it as disposable. However, the good news is that this is not impossible.

6. Edible packaging of the future.

One thing that has become clear is that the future of packaging is changing. We are shifting towards more eco-friendly alternatives that can greatly reduce waste, plastic packaging and other toxic substances, setting a new standard for sustainable projects.

Although further research and development is required to make this new sustainable packaging option fit for large-scale application, the current findings indicate significant progress. As more policies are altered and resources invested in sustainable, edible packaging, we are bound to see innovation in many different industries.

Changes can be expected in different industries, not just with edible packaging, but with sustainable packaging in general.

About Printing Craftsmanship

What is hot stamping, and where is it used?

Hot stamping is a printing process that applies metallic or pigmented foil to a surface using heat and pressure. It is widely used for:

Luxury packaging (cosmetics, wine, gourmet foods)

Business cards

Event invitations

Labels and stickers

High-end stationery

Folding Boxes

Can you provide me with a die-cutting line template?

We will provide a die-cutting line template after you place an order for samples or products.

Special Shape Boxes

How long does it usually take from design confirmation to delivery?

The lead time is usually 15-25 days, depending on the production of the order

Rigid Lift-off Box

Can I print on the inside of the box?

Yes, you can print any effect you want on the inside.

About Us

How to start the mass production?

Once received the 30% deposite, we will arrange the mass prouction.The balance need to be paid before delivery.

Start Your Packaging Journey Today

Discover Our Curated Collection of Bespoke Packaging Cases & Tailored System Solutions

© 2025 WINPACK PRINTING. All rights reserved

Wenhua Printing packaging

winpackprinting

Winpack Printing