What is a Dieline in Packaging & Print?

When you go shopping for and design your new custom boxes, you will hear the word 'dieline' thrown around a lot! To newcomers, it may sound like a technical term that only a packaging expert could understand. But the fact is that it is quite straightforward and very important for creating your own packaging.

In this article, we will discuss everything you need to know about dielines, including how to read and utilise them for your own custom packaging projects.

1. So, what is a dieline?

In print and packaging, a dieline is a design plan that shows the exact layout of the packaging. It acts as a guide for designers and manufacturers, ensuring that all visual aids such as cut lines, fold lines, bleed lines and safe zones are indicated on its flattened surface before production. Due to its flat construction, you can view all sides of the box, format your artwork to your particular packaging requirements, and see exactly where and how your artwork will be applied.

2. Why are dielines important?

The first thing you see of your final packaging design is the dieline. They are essential at every stage of the packaging design process, from visualisation of the final design to identification of errors, refinement of the layout, die-cutting, prototyping and mass production.

-- They are also important for proofreading and error detection.

Dielines are an important part of packaging design, enabling designers to examine, spot and rectify any errors in artwork, structure, typography or size before finalising the design. Therefore, to achieve the desired result, several steps of revisions and refinements must be completed. Once the dieline is finished, the next step is to preview your design using 3D rendering software.

-- Final die-line 3D visualisation.

Using your dieline in a 3D rendering programme such as Pacdora or the Esko Studio Illustrator plugin will provide you with a digital mock-up showing how the packaging will appear once assembled. This is an important step that ensures the correct arrangement and positioning of visual components, and helps to identify design flaws that could not be spotted in 2D. The 3D visualisation also allows you to assess the feasibility of your design options, including the functionality of fold lines and perforations, the correctness of cut lines, the visual effect of colours, and even the size and style of the box. Providing these 3D mockups to stakeholders or clients can improve communication and approval processes, making the packaging design workflow more efficient and error-free.

-- Die cutting

Once printing is complete, your packaging materials are subjected to a process known as die-cutting, whereby they are cut to your desired shape. Manufacturers use your die lines to make a custom die board. The laser engravers are programmed to cut the die layout on the die board, which is then pressed onto the packaging materials to accurately cut out the die pattern. It is important to have your dieline design completed at this stage to ensure accuracy. You can read more about die cutting in our blog post.

Prototyping

Prior to mass production, request a prototype of your completed packaging based on your dieline to perform a final check of the structure and design.

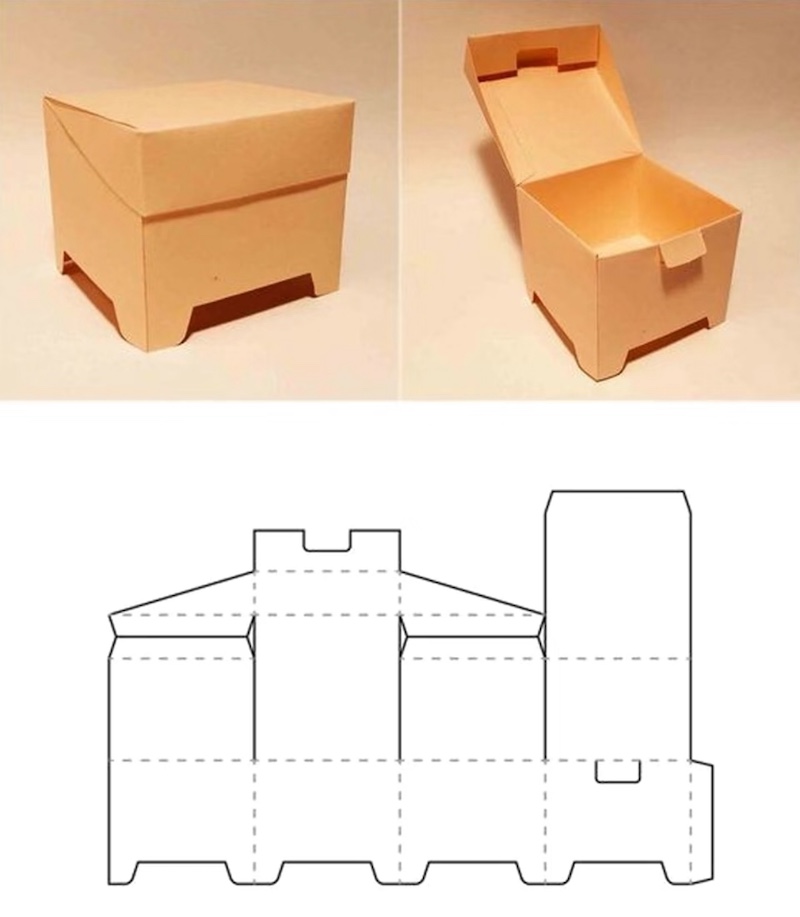

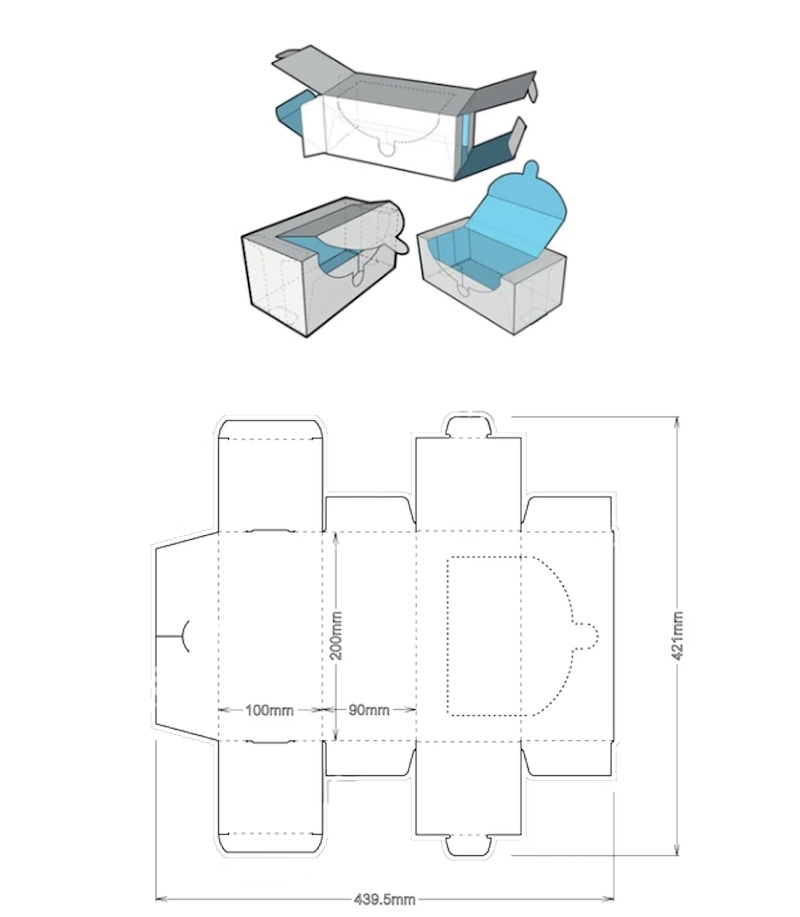

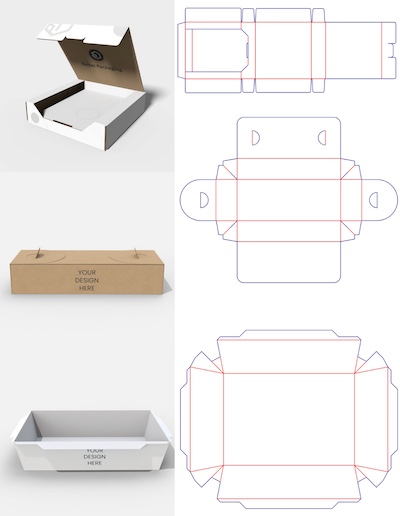

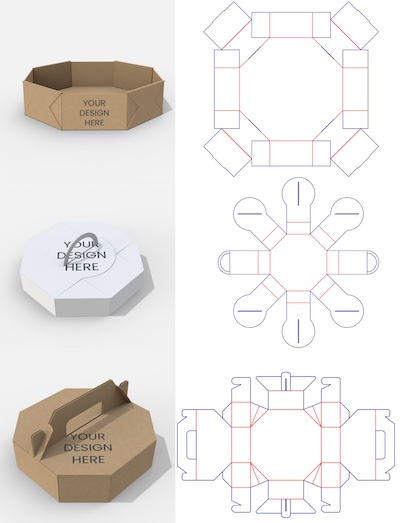

3. Dieline examples

The following examples demonstrate the appearance of dielines for various types of packaging.

4. How to read dielines

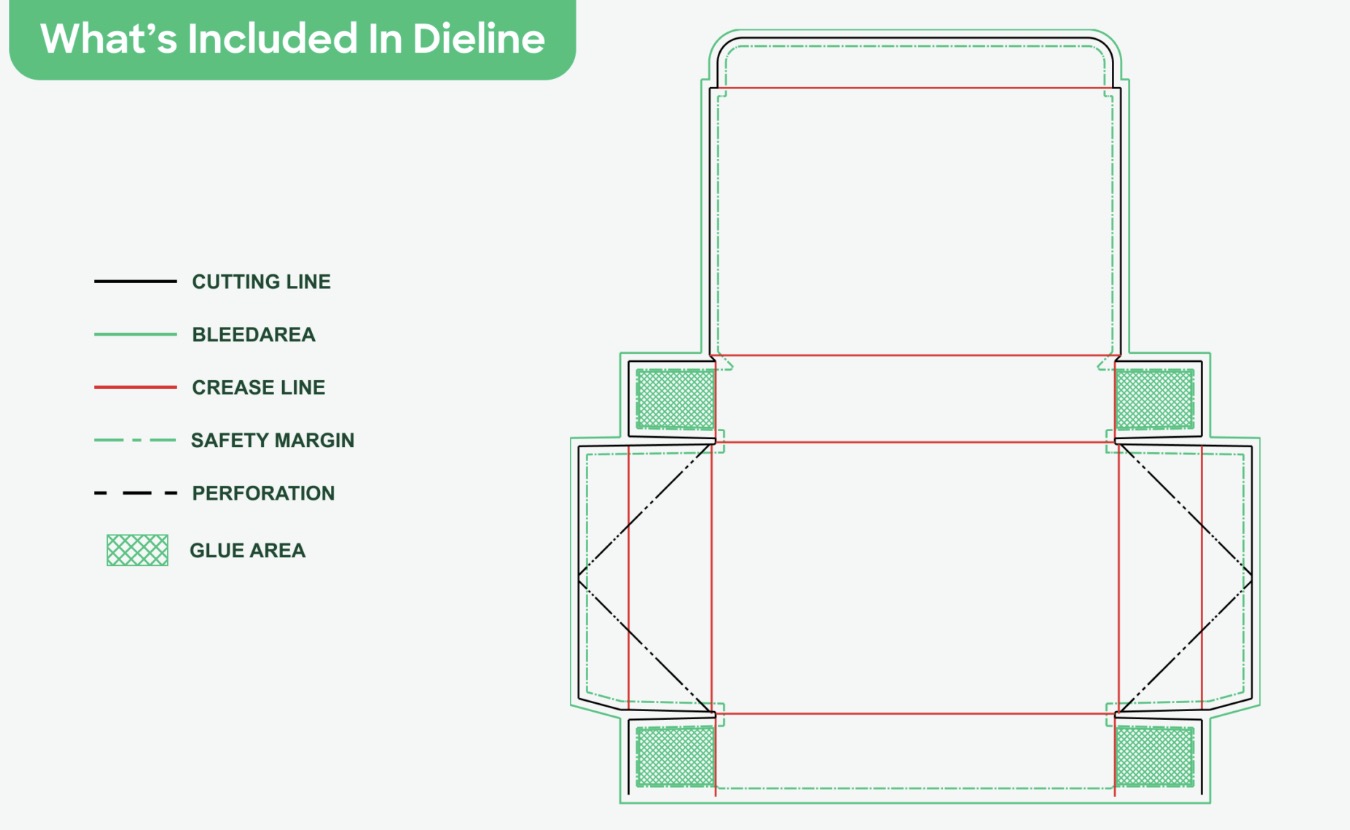

A dieline is key to producing your own packaging, and is therefore an important tool for anyone in the packaging and printing business. This technical drawing contains components that instruct manufacturers on how to create packaging that is accurate to your design. Although particular needs, labelling, colours and terminology may differ slightly according to the manufacturer and software used, the fundamental aspects of dieline design remain consistent throughout the industry. Below, we will consider what a dieline should contain:

Cut lines (trim lines): These are solid black lines showing where the die-cutting machine will cut. These lines represent the final size of your packaging design, i.e. the size of the package after trimming.

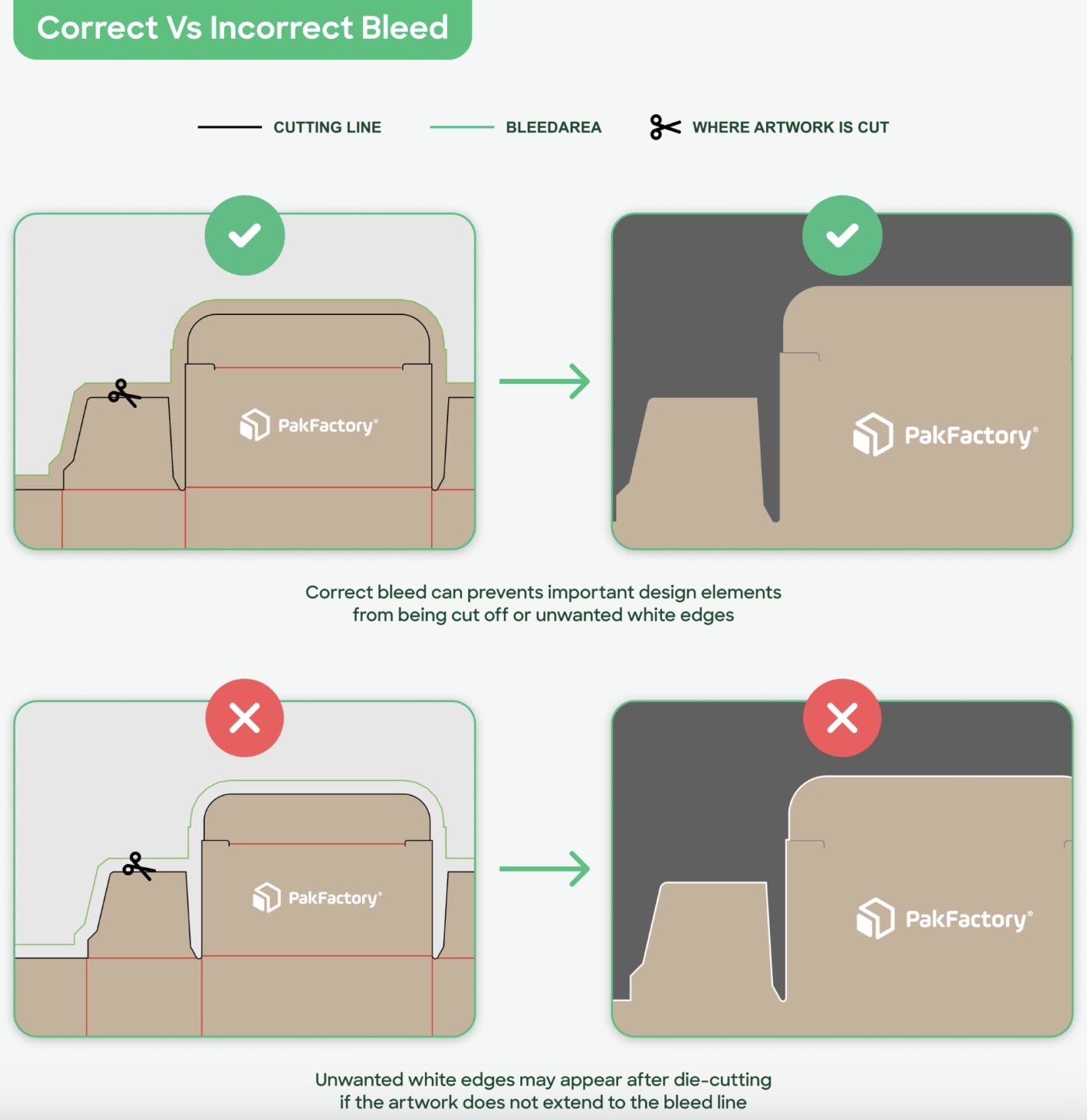

Bleed lines are solid green lines that indicate the additional printing area, known as the bleed area, which extends beyond the cut line. This additional space is usually 0.125 inches (3 mm) beyond the last cut line to allow for slight movement of the packaging material during machine cutting. Therefore, extending your artwork to the bleed line ensures that no significant design features are lost and that there are no white edges in the final product. The simplest way to achieve this is to extend less important details, such as background images or graphics, to the bleed line, while keeping important elements, such as text and logos, within the safe area inside the cut line.

Fold lines (crease lines) are represented by solid red lines and mark where your packaging will be creased and folded to create its final 3D shape.

Safety lines (margin lines) are represented by green dotted lines and indicate the safe area for vital graphic elements such as logos and text. Place these elements within the safety lines to ensure they are not cut off during trimming. This means that, even if the die-cutting machine moves slightly beyond the cut line, nothing inside the safety lines will be cut.

Perforation lines are represented by black dotted or dashed lines and indicate where the packaging should be punched to make it easier to fold or tear. They are frequently used in packaging that needs to be easily opened or separated.

Glue tabs (seal tabs) are represented by green criss-cross tabs and indicate where glue or adhesive should be applied when making your packaging.

5. How to Create Dielines

If you are working with a packaging designer or manufacturer, you probably won't need to worry about creating the dieline yourself, as this is the designer's job. However, if you are a business owner or someone who wants to work in the packaging industry, it can be useful to know which software and technical specifications are needed to create a dieline. This knowledge enables you to convey your vision to the designer or manufacturer, ensuring that all elements and settings in your print-ready file are correct and there are no mistakes. We will take you through the fundamentals and key areas to focus on below.

--Apply structural design software

Professional software is required to develop a dieline. ArtiosCAD is an industry-standard structural packaging design tool that can be seamlessly integrated with manufacturing and die-cutting processes. It enables designers to create accurate and intricate packaging designs while taking into account factors such as the type of material, weight, and thickness. This helps to identify quality issues and ensures that the design is viable and can support the weight of your products.

It is also important to be able to develop a 3D image of your dieline. Tools such as ArtiosCAD provide an opportunity to visualise the product and packaging without the need for a physical sample.

Other popular vector art software, such as Adobe Illustrator, is better suited to creating artwork, graphics, and visual features of packaging. However, it is not suitable for developing dieline structures because manufacturing machines cannot accept it directly and require modifications or conversions for printing or cutting.

For novices or when you want to use standard packaging designs, online tools such as Pacdora offer a wide range of template libraries that can be used to easily create dummies and mock-ups. These tools make life easier, allowing you to focus on creating eye-catching packaging.

--Define the flat size and layout

Another important step is to define the size and layout of the packaging flat to be used in your dieline. This involves deciding on the size and arrangement of the design elements on a single piece of packaging material.

The most effective way to ensure that the dielines are correct for your custom packaging is to provide the packaging designer with existing designs or boxes that are similar to what you have in mind. This gives the designer a starting point and allows you to make adjustments until the final packaging design is agreed upon.

If you are dealing with a manufacturer, they will probably send you a completed dieline template containing bleed requirements and manufacturing notes. If you are using software such as ArtiosCAD or Pacdora, there are ready-made libraries to help you create a dieline. You just need to place your artwork on the dieline and ensure that the colours are properly matched.

--Include dieline markers

The design of dieline markers is an indispensable aspect of the process. Ensure these signs are present and clearly marked, as they indicate where the packaging will be cut, folded, and glued. These manuals are essential for the production department to produce and assemble the packaging properly and effectively.

--Output format

When creating your packaging dieline, it is important to save the final result as an editable vector file (such as a PDF or AI file) with the colour mode set to CMYK. These formats are regarded as industry standards because they are precise in design, guarantee print quality and can be easily modified before and during the production process. If you have specialised structural design software such as ArtiosCAD, you can quickly export your dieline as an AI file. This file can then be imported into a vector artwork programme, such as Adobe Illustrator, where you can add your artwork and make any necessary design changes.

Read our guide here for a step-by-step procedure on how to prepare a piece of artwork.

6. The Die-Cutting Process

Once you have printed your dieline onto the packaging material, it passes through the die-cutting stage. Imagine it is a giant cookie cutter, known as the metal die plate, which is specially designed to fit the outline of your packaging. The packaging material is initially placed in a die-cutting machine, where strong rollers and cutting plates press the metal die through the material with a calculated force. This creates clean, accurate cuts that fit your die-line requirements exactly, and the packaging is ready to be folded into its final 3D form. Read this article to find out more about the die-cutting process.

7. Need help creating a dieline?

As you will have noticed, dielines are important for the final appearance of your package. It is therefore necessary to understand what dielines are and how they are formed.

Not a designer or manufacturer? No worries! Winpack Printing provides a complete range of services for all your custom packaging requirements, including design and structural engineering.

OEM Services

What is OEM packaging, and how can Winpack Printing help?

OEM (Original Equipment Manufacturer) packaging refers to custom-designed packaging solutions tailored to a brand’s specifications. At Winpack Printing, we provide end-to-end OEM services, including design, proofing, printing, and production, to help you create high-quality, market-ready packaging that aligns with your brand identity.

What is the minimum order quantity (MOQ) for OEM orders?

Our MOQ varies depending on the type of packaging and material used. We offer flexible MOQ options to accommodate both small businesses and large-scale manufacturers. Contact us for a tailored quote based on your needs.

About Printing Craftsmanship

How does UV printing work?

UV printing uses ultraviolet light to cure ink instantly, resulting in vibrant colors, water resistance, and high durability. It is commonly used for packaging, signage, and promotional items.

What are the advantages of embossing?

Enhances the visual and tactile appeal of printed products.

Creates a premium and professional look.

Improves brand recognition with distinct textures.

Increases durability as the embossed design remains intact over time.

About Us

How soon we can get a sample?

Usually,reference sample within 2 days. Customized sample need 5-7days.

Start Your Packaging Journey Today

Discover Our Curated Collection of Bespoke Packaging Cases & Tailored System Solutions

© 2025 WINPACK PRINTING. All rights reserved

Wenhua Printing packaging

winpackprinting

Winpack Printing