Embossed Foil Stamping, Embossing and Debossing – How to Create High-End Prints

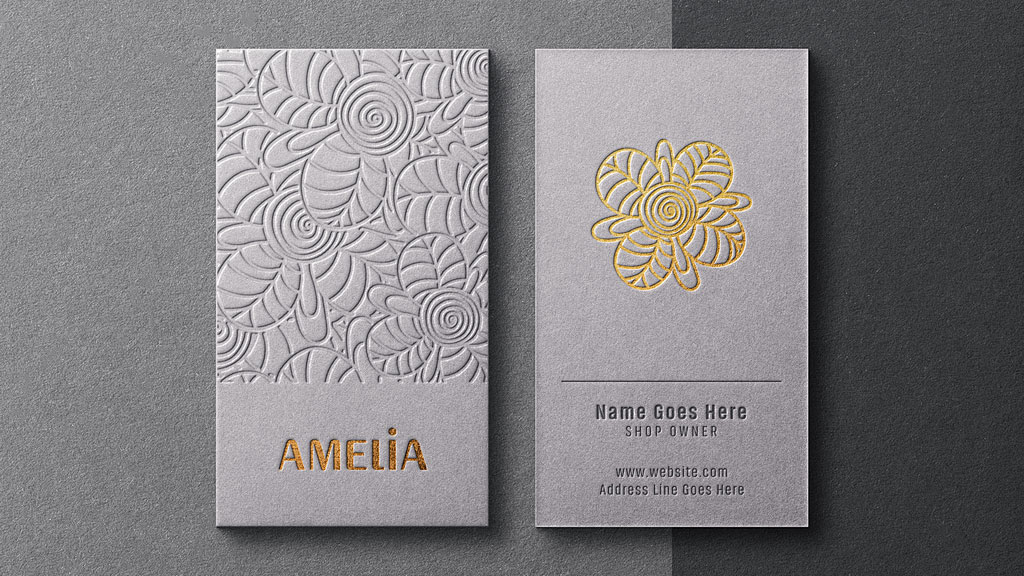

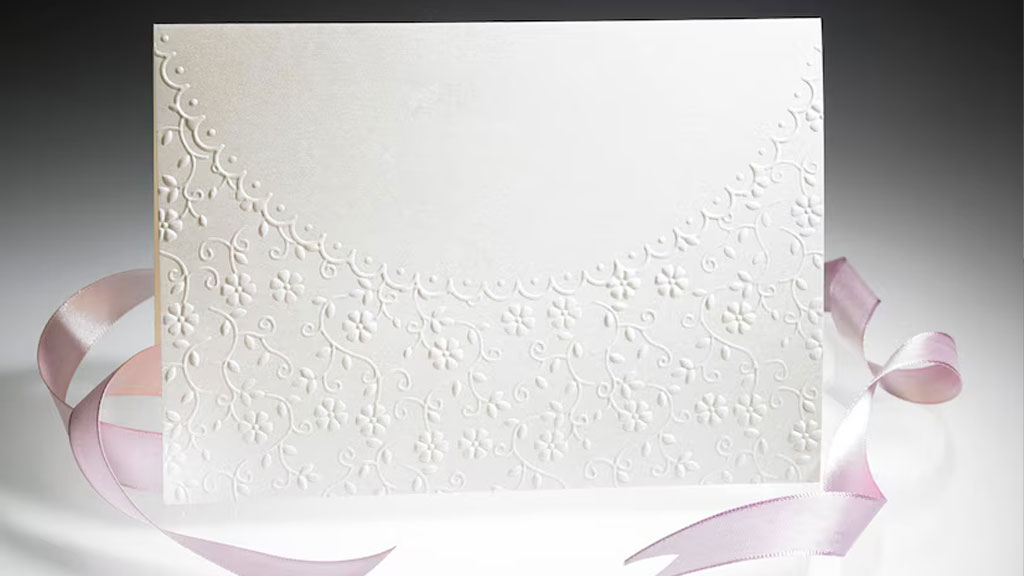

In the world of premium printing, texture and finish play a crucial role in elevating the final product. Among the most sought-after techniques are embossing, debossing, and embossed foil stamping. These finishing processes add a tactile and visual appeal, making business cards, packaging, invitations, and luxury branding materials stand out. This article explores these techniques and how to use them to create high-end prints.

In the world of premium printing, texture and finish play a crucial role in elevating the final product. Among the most sought-after techniques are embossing, debossing, and embossed foil stamping. These finishing processes add a tactile and visual appeal, making business cards, packaging, invitations, and luxury branding materials stand out. This article explores these techniques and how to use them to create high-end prints.

Understanding the Techniques

Embossing

Embossing is a technique that creates a raised design on the printed surface. This effect is achieved by pressing the paper or cardstock between two dies – one raised and one recessed – to create an elevated impression.

Key Features:

No ink or foil is necessarily required.

Adds a sophisticated and elegant texture.

Works well with logos, patterns, and typography.

Debossing

Debossing is the opposite of embossing, where the design is pressed into the surface, creating a sunken effect. It provides a subtle, understated look and works exceptionally well with soft-touch paper and leather materials.

Key Features:

Can be used alone or combined with ink and foil.

Adds depth and dimension to printed pieces.

Ideal for creating minimalist, high-end aesthetics.

Embossed Foil Stamping

Embossed foil stamping combines embossing with foil application, producing a luxurious, shimmering effect. This method involves applying metallic or pigmented foil onto the raised design using heat and pressure.

Key Features:

Adds a reflective, premium look.

Enhances logos, monograms, and luxury packaging.

Available in gold, silver, holographic, and various colored foils.

How to Create High-End Prints with These Techniques

1. Choose the Right Material

The quality of the paper or cardstock is crucial. Heavier stocks (300gsm or more) work best for embossing and debossing, as they retain the texture better. Soft-touch, uncoated, or textured paper enhances the tactile effect.

2. Design with Depth in Mind

When designing for embossing or debossing:

Use vector-based artwork for precision.

Keep designs simple and bold for maximum impact.

Consider line thickness and spacing to prevent distortion.

3. Select the Best Foil Type

For embossed foil stamping, choosing the right foil is essential:

Metallic foils (gold, silver) for classic luxury.

Matte foils for a modern, subtle shine.

Holographic foils for a futuristic, eye-catching look.

4. Optimize the Printing Process

Work with experienced printers who specialize in these techniques. The die-cutting process must be precise to ensure sharp and defined impressions. Additionally, test different levels of pressure and heat to achieve the best effect.

5. Combine Techniques for Maximum Impact

For ultra-luxurious designs, consider combining embossing, debossing, and foil stamping with:

Spot UV for contrast.

Edge foiling for a sophisticated touch.

Soft-touch lamination to enhance tactile appeal.

Applications of These Techniques

Luxury Business Cards – Adds elegance and professionalism.

Premium Packaging – Enhances brand perception.

Wedding Invitations – Creates an opulent feel.

High-End Book Covers – Increases aesthetic and tactile appeal.

Conclusion

Embossing, debossing, and embossed foil stamping are powerful techniques that can transform standard prints into premium works of art. By selecting the right materials, designing thoughtfully, and working with skilled printers, you can create striking, high-end printed materials that leave a lasting impression.

About Printing Craftsmanship

What is the best printing technique for business cards?

It depends on the desired effect:

Hot stamping for a premium metallic finish.

Embossing for a raised, tactile design.

Spot UV for glossy highlights on specific areas.

Digital printing for quick, affordable, and full-color printing.

What is screen printing used for?

Screen printing is ideal for printing on a variety of surfaces, including:

Fabric (t-shirts, tote bags)

Plastic (bottles, packaging)

Paper (posters, packaging)

Metal and glass (signs, promotional products)

About Us

How long does shipping take?

Air freight options range from 7-21 days, while ocean freight options range from 26-71 days. If you need some units expedited earlier, consider splitting your shipment between air and ocean!

OEM Services

What quality control measures do you have in place?

We implement strict quality control throughout our production process, including:

ISO-certified quality management systems

pressSIGN color management for consistent printing quality

ERP production tracking for precision and efficiency

Rigorous inspections at every stage of production

Can you help with packaging design if I don’t have one?

Yes! Our experienced design team can assist in creating packaging that aligns with your brand’s vision. We can develop concepts, offer material recommendations, and ensure compliance with industry standards.

Start Your Packaging Journey Today

Discover Our Curated Collection of Bespoke Packaging Cases & Tailored System Solutions

© 2025 WINPACK PRINTING. All rights reserved

Wenhua Printing packaging

winpackprinting

Winpack Printing