Subtractive Color Mixing-A Complete Guide

The method of shaping color and its manipulation is something central in the world of art, design, and technology, and one should consider this element to be central in shaping the visual experience. The concepts of subtractive color mixing based upon the reality that light and pigments interact are critical to the industries that involve working with real media like printing, painting, and textile design. This paper examines the physics, uses, and advances of subtractive color mixture in a bid to give in-depth details to interested parties, including practitioners and amateurs.

- 1. Subtractive Color Mixing Introduction

- 1.1 Definition and Importance

- 1.2 Historical Context

- 2. The Science Behind Subtractive Colors

- 2.1 How Subtractive Colors Work

- 3. Subtractive vs. Additive Color Mixing

- 3.1 Key Principles

- 3.2 Strengths and Applications

- 4.Primary and secondary colors in subtractive models

- 4.1 CMY: The Subtractive Primaries

- 4.2 Creating Secondary Colors

- 4.3 Science On The Sense

- 4.4 What Black (K) Does in CMYK

- 5. Practical Applications of Subtractive Color Mixing

- 5.1 Printing Industry and CMYK

- 5.2 Workflow in Printing:

- 5.3 Applications:

- 5.4 Painting and art

- 5.5 Techniques in Subtractive Color Mixing:

- 5.6 Other Industries

- 6. Challenges and Limitations

- 6.1 Pigment Imperfections

- 6.2 Color Gamut Restrictions

- 6.3 Environmental Concerns

- 7. Subtractive vs. Additive: A Deeper Comparison

- 7.1 Fundamental Differences

- 7.2 Real-World Applications and Relevance

- 7.3 Why Both Models Matter

- 7.4 Application Scenarios

- 7.5 Bridging the Gap

- 8. Innovations and Future Trends

- 8.1 Advances in Printing Technology

- 8.2 Sustainable Color Mixing

- 8.3 Integration with AI and Digital Tools

- 9. Conclusion

1. Subtractive Color Mixing Introduction

1.1 Definition and Importance

Subtractive color mixing is a procedure of creating color through the suppression of predetermined wavelengths of light in a medium, competent in sophisticated colors, such as pigments, dyes, or inks. Subtractive mixing differs in that it does not mix sources of light, unlike in additive mixing where light sources are combined so as to produce colors visible on the screen.

This is the fundamental principle in businesses like printing, painting, and design where it is very necessary to ensure that the color is printed properly. Based on the primaries of subtractive color systems (cyan, magenta, yellow (usually in combination with black in CMYK color model) one can produce a wide range of hues. The knowledge of subtractive color mixture helps artists, designers, and engineers when it comes to manipulation and control of color to a specific degree of precision in physical media.

1.2 Historical Context

The theory of subtractive color mixing has deep roots in the evolution of color science and art. Historically, the RYB (red, yellow, blue) model was the foundation of color theory, used extensively in traditional painting and teaching. This model, however, was based more on observation than scientific accuracy.

The introduction of modern science brought an increase in the knowledge of light and pigments and soon the CMY (cyan, magenta, yellow) concept of subtractive mixing was adopted. When compared with RYB, CMY is less ideal than the way in which light is reflected and taken up by real surfaces. The late nineteenth century onward saw perhaps the first instance of printed color development in the form of the CMYK model in printing which added the black (K) to overcome the shortcomings of the original three colors. The innovation transformed the way colors are reproduced and instead of obtaining blurred contrasts and inaccurate representation of images; the printers were now able to obtain sharper contrasts and more real representation of the images.

In both its artistic origins and in its technological use, subtractive color mixing is a mainstay of our perception and use of color in physical appearances.

2. The Science Behind Subtractive Colors

2.1 How Subtractive Colors Work

Subtractive colors work by shining certain big portions of the light and this is what applies the color to other lights making it fade. By reflecting some colors and absorbing others, the material will have absorbent properties of some of the wavelengths when the white lighting that has all the colors hits an object or surface with pigments or dyes. What we see are the reflected wavelengths which make us experience a color.

As an example, we have blue pigment. In case of white light falling on the surface of the object-painted in blue then most of the red and green wavelengths fall in the pigment and the light kept within this pigment is the wavelength of blue and therefore only this red, green wavelength travels back. Subtractive color mixing is based on this selectivity of absorption. A large variety of colors can be achieved by mixing pigments each of which absorbs different wavelengths.

This principle is important in other fields like printing, textiles and art where it is necessary to have control of colors to the highest levels. Very much depends on the interaction of light, pigments, and surfaces in order to see what you want to see.

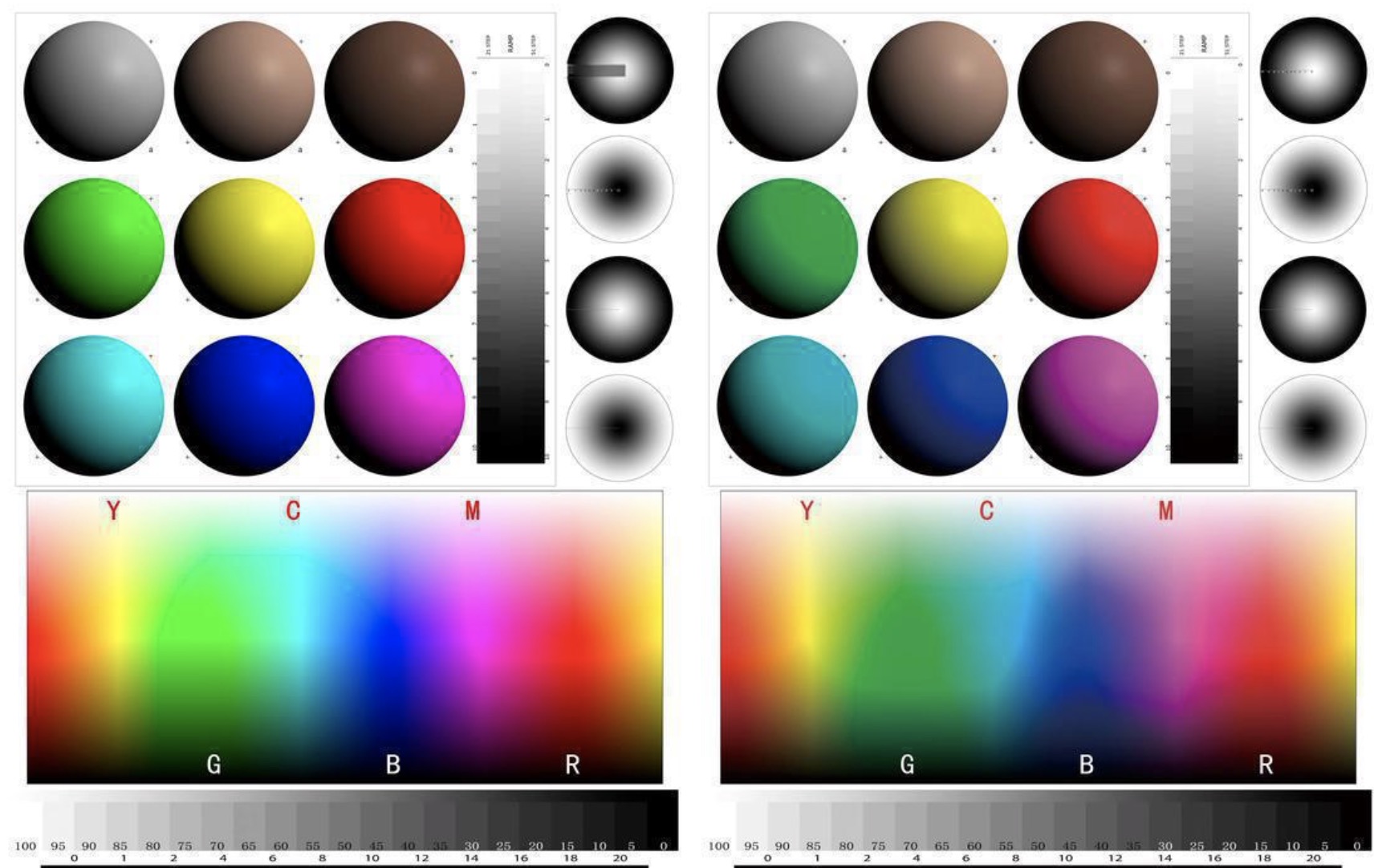

3. Subtractive vs. Additive Color Mixing

Two opposite theories of color formation are subtractive color mixing and additive color mixing based on different physical phenomena and applicable to various uses.

3.1 Key Principles

CMY: Subtractive Mixing:

Subtractive mixing is a combination of pigments or inks which selectively absorb certain wavelengths of light, and reflect others. With the mixture of cyan, magenta and yellow, more wavelengths are absorbed and this gives darker colors. To illustrate, cyan, magenta and yellow absorb red, green and blue lights respectively.

RGB- Additive Mixing:

Additive mixing is based upon the emitted light sources whereby colors are mixed together to form more intense shades using red, green and blue light. The three colors combined in this way at maximum strength result in white.

3.2 Strengths and Applications

Subtractive Mixing: Most appropriate on physical media including printing and painting where there is physical interaction of a substance with a source of light to create color.

Additive Mixing: Is predominant in digital spaces like screens and stage lights where the light that is emitted is simply shown to the eyes of the viewer.

With this knowledge on the above fundamental differences professionals can be able to use and leverage the best out of each mode to the best of their abilities.

4.Primary and secondary colors in subtractive models

4.1 CMY: The Subtractive Primaries

Subtractive color mixing is based on the subtractive primary colors; cyan, magenta and yellow. These three colors have been found to interact with light where the wavelengths of light are absorbed and reflections take place:

Cyan (C): Reflects blue and green wavelengths, red light is absorbed to obtain its typical cool blue-green color.

Magenta (M): The magenta causes the absorption of a green color and has a reflective blue and red, which makes the color appear a bright purplish-red.

Yellow (Y): Absorbs blue and reflects red and green producing the warm gold-yellow color.

Each of the three major colors has a different role in subtractive color models, and all of them make it possible to obtain the vastness of hues through the interaction of their reflective properties. These hues suit physical media quite better, having physical elements like pigments or inks that interacts with light to create visible colors in printing and painting.

4.2 Creating Secondary Colors

Subtractive models of color receive the addition of two primary colors whose individual components bring the individual absorption and reflection characteristics. This is the essence of subtractive mixing of colors and is common in designing, art and printing.

When cyan and yellow are combined:

Process: Cyan filters pass short and medium wavelengths (blue and green) and yellow filters absorb additional short wavelength (blue). This leaves green (a medium wavelength) to be reflected.

Outcome: The middle wavelength excites the green color cones in the human eye and the brain recognizes green to be the prevailing color.

Examples of Use: Green has always been a color commonly employed in nature-oriented design and branding and on print publications to create a feel of freshness and vitality.

When yellow and magenta are combined:

Process: The yellow filters pass medium and long waves (green and red) whereas the magenta absorbs the medium waves (green), leaving the long waves (red) to perform dominant wavelength.

Outcome: The long wavelength achieves effect over the L-cones in the eyes causing the production of red color.

Use Case: Red is one of the important colors to portray energy and passion, and it cannot be eliminated in the arts and advertisements.

When magenta and cyan are combined:

Process: The magenta carries the short and long wavelengths (blue and red) and cyan absorbs the long wavelengths (red). This leaves blue(short wavelengths) as the reflected light.

Outcome: Short wavelength attacks the S-cones and the brain responds with blue.

Use Case: Blue is abundant when working on the corporate branding and design due to their associations to trust and professionalism.

4.3 Science On The Sense

The process of subtractive mixing does also not only depend on the physics of reflected and the absorption of light, but it also depends on how our eyes and brain combine these wavelengths through the activation of cone cells. Pigments have the ability to make a broad assortment of secondary colors by carefully filtering and merging light.

4.4 What Black (K) Does in CMYK

A crucial component to the CMYK model is the black component (k) owing to the shortcomings of the reproduction of color solely by means of the cyan, magenta and yellow colorants.

In theory, a mixture of 100 percent of the three colors -- cyan, magenta, and yellow could offer black. However, in the real world, the mixture offers a dark, muddy brown because of flawed pigments and inks. Introducing a pitch of black ink into the mixture improves the model in a number of ways:

Better Contrast: Better contrast can be achieved with black ink, with more discernible edges and details, such as in text, or in high-contrast images.

Increased Depth: It generates deeper shadows and a deeper feeling of dimension leaving images to look much brighter and natural.

Efficiency: Black ink lowers the necessity of using cyan, magenta and yellow to obtain dark tones, and results in ink and print quality savings.

In advertising printing, the black ink plays a main role in printing high quality pictures to ensure that the images are color resembling and the print is of superior quality. It also gives a greater control on tonal gradation leading to the professional finish that has become the expectation in contemporary print media.

5. Practical Applications of Subtractive Color Mixing

5.1 Printing Industry and CMYK

CMYK system is the core of print business without which it would be impossible to print the colors in the desired form with the precision on the physical mediums like papers, packages and tissues. CMYK (Cyan, Magenta, and Yellow, and Key/black) is based on a subtractive mixing of colours; it is created by combining inks to white substrate, where each colour absorbs certain wavelengths of light and reflects others to create bright colours.

5.2 Workflow in Printing:

Color Separation: Digital arrangements in RGB are transformed to CMYK, the colours can be printed out.

Ink Layering: Printing machines apply the combination of colors (cyan, magenta, yellow, and black) in different portions to obtain the intended color.

Halftoning: Small dots of each ink are inserted in patterns in order to create an impression of gradients and new shades, providing complete range of colors.

5.3 Applications:

Magazines: The glossy print should have top-quality visual, which requires CMYK as a color technology to have higher color accuracy and excellent detail.

Packaging Design: Brand color scheme and descriptive graphics in product packaging are done using CMYK to give its characteristic uniformity across print batches.

Through the Correction Model of Yellow inking, the printing sector facilitates the reproduction of bright, precise, and simplified color, and it is one of the printing industries that cannot do without in terms of folding cartons to paper bags.

5.4 Painting and art

The traditional art has its foundations on subtractive color mixing techniques to apply during painting. Artists mix and layer pigments to achieve a particular color each pigment has a particular absorption and reflection of the light. This enables a lot of palette in terms of colors, tones and shades.

5.5 Techniques in Subtractive Color Mixing:

Pigments Layering: Pigments are transparent or semi-transparent, so artists are able to make a picture gain depth and complexity by layering different colors. As an example, glazing techniques cover the application of the thin layers of paints to create effects of the luminous passages.

Color Blending: Adding the different primary colors (red, yellow and blue in traditional art) in a palette to make secondary and tertiary colors.

Color Harmony:

Artists have placed a lot of attention on the ratios of pigments to effect particular moods or the effects of vision. As an example, incorporation of complementary color may help eliminate too-saturated coloring and have a compositionally balanced piece.

Subtractive color mixing is still vital in painting and through it, an artist is enabled to transfer their mind-image into a work of art whose colour interrelationships are deep and powerful.

5.6 Other Industries

Subtractive color mixing is used in things beyond printing and painting and is actually required in any number of industries where precise color control is needed.

Textile Dyeing: The goal of matching precise fabric color can be done through the principles of subtractive as dyes are blended together. An example is that a designer can combine cyan and yellow dyes in order to make a lively green in his fashion collection.

Automotive Coatings: The automobile manufacturers rely on the subtractive method of color mixing to come up with the required hues and effects to enable the paint finish to maintain a constant brand identity using the element of attractiveness.

Fashion Design: Those involved in Fashion design use subtractive mixing to create unique prints, patterns and color combinations to be used in clothing and accessories to coincide with the changes in season and what the market wants.

Such industries rely on the principles of subtractive color mixing to come up with products that satisfy both aesthetic and functional needs. Subtractive mixing is key to innovation and quality whether it comes to matching the fabrics to the vision of a designer or producing automobile finishes that last and don’t dull out.

Such industries rely on the principles of subtractive color mixing to come up with products that satisfy both aesthetic and functional needs. Subtractive mixing is key to innovation and quality whether it comes to matching the fabrics to the vision of a designer or producing automobile finishes that last and don’t dull out.

6. Challenges and Limitations

6.1 Pigment Imperfections

The nature or quality of the pigments has a big role to play in accuracy of subtractive color mixing. Defective pigments cannot sometimes absorb the light entirely at the wavelengths they are supposed to be, which brings about unwanted light changes and poor saturation. To give an example, a cyan pigment might unintentionally reflect some red light, so when it is mixed with yellow, the resulting greens will be squelched or improper.

Addressing Absorption Issues:

Superior Pigments: Manufacturers are working to develop cleaner pigments with more definite absorption characteristics, which lead to the fidelity of colors.

Optimized Ink Formulas: Ink is an optimized mix of chemicals designed to minimize erraticities in light absorption through additional stability and consistency.

Overprinting Techniques: The use of well-placed layers of inks in printing may fill the gaps left as a result of an imperfect coverage by a color, thus faithfully representing the intended color.

Although pigments themselves are imperfect, active research in new materials and methods continues to reduce the effects of each one; this has increased the predictability of subtractive color mixing.

6.2 Color Gamut Restrictions

Though commonly used in practice, the CMYK color model has color gamut limitation due to the physical properties of the colors used in this color model. Some of the brightest colors, e.g. the blues and greens, are out of the CMYK gamut, and therefore inexact.

Addressing Gamut Limitations:

Pantone Color Matching System: To complement CMYK, designers and printers most frequently use Pantone, which is a standardized system of color. Pantone also gives exact formulations of colors that can not be replicated by CMYK and creates consistent reproduction across the mediums.

Expanded Gamut Printing: One way in which printing is advancing is by using more colors in the print (e.g. orange, green, violet) to give a wider gamut that provides richer and truer color.

Color Management Software: Sophisticated software is available to inform the designer of future color limitation through previewing the colors as they will look in CMYK and making certain modifications thereof prior to printing.

Nonetheless, CMYK still cannot produce brightness or the palette of the additive color model such as RGB, which is even able to reproduce almost all the visible wavelengths.

6.3 Environmental Concerns

There are grave environmental issues related to the use of pigments and dyes in the subtractive color mixing especially in printing and textile industries. Most of the traditional pigments utilize chemicals that may be toxic or disposable causing pollution and wastage of resources.

Sustainable Strategies:

Eco-Friendly Pigments: Creating non-toxic and biodegradable pigments will also lessen environmental consequences of production as well as waste.

- Recyclable Materials: Recycling of materials promotes waste reduction in the processes by using recyclable materials, e.g. on the paper or fabric.

- Efficient Energy Process: Current printing and dyeing techniques demand low water and energy consumption reducing footprints on the environment.

Regulatory Compliance: The Environmental standards are being implemented in a more stringent manner by governments and even industries stimulating the choice of sustainable strategies.

Implementing eco-friendly innovations does not only make subtractive color mixing processes in line with the overall world sustainability theories but also contributes to operational efficiencies. As an example, an environment-friendly practice like using water-based inks can also decrease the drying periods, and recyclable materials can ensure less expenses are needed to produce a certain amount of a product, meaning that businesses and the environment are winning in terms of the benefits.

7. Subtractive vs. Additive: A Deeper Comparison

7.1 Fundamental Differences

The principals of subtractive and additive color mixture contain different elemental extraction, but with the complementary relationship, an easy interconnection in regards of physical media and digital media integration is possible.

7.2 Real-World Applications and Relevance

Subtractive Mixing (CMY)

Pivotal to physical media, including printing and painting, in which pigments contained within a physical medium absorb and emit light to make color with.

As an example, the CMYK model helps produce colors in magazines, packaging, etc., accurately.

Additive Mixing (RGB)

The essential feature of online environments, such as monitors, televisions, and smartphones, whose light sources are put together to bring out bright, high-resolution colors.

The wider color gamut of RGB is more suitable in web design, advertisement on the internet and video production.

7.3 Why Both Models Matter

These models are not interchangeable but instead complement each other:

Filling the Gap: Designers will have the necessity to shift back and forward as the design is in RGB format and when one wants to print then the platform needs to be changed to CMYK format. This will need special modifications because gamuts of the two models are not similar.

Consistency: Proper knowledge of these models aids professionals in focusing on the good reproduction and consistency of colors used across platforms providing a solid user experience.

Summary: Subtractive mixing is indispensable for physical media, while additive mixing excels in digital environments. Together, they empower professionals to create visually compelling and accurate designs across all mediums. By leveraging their strengths and addressing their limitations, designers can achieve seamless cross-platform results.

7.4 Application Scenarios

Each model serves distinct purposes based on how colors are displayed or reproduced:

- Printing CMYK:

Physical printing uses subtractive mixing as the norm. The CMYK model overlays inks to make a complete range of colors printed on white surfaces.

Some common uses are books, magazines, packaging and advertising. As an example, CMYK makes sure that brand colors are the same every time several prints are made.

- Digital Forms: RGB:

The most suitable to devices that give off light like screens is the additive mixing. The RGB has a wider palette of colors and can support a wide variety of colors (millions), subsequently best suited with life, animated graphics.

Employed in such work as web design, digital art and video production.

Choosing the Right Model:

The choice between CMYK and RGB depends on the medium:

CMYK: When designing for print, ensure your project uses the CMYK model to reflect real-world pigment interactions.

RGB: For digital projects, RGB captures the vividness achievable with emitted light.

7.5 Bridging the Gap

The designers usually operate between the digital and the physical platform, and there is a need to achieve smooth transitions between RGB and CMYK. Nevertheless, these models can be hard to work with because of the diversified color gamuts.

Strategies for Conversion:

Adapt Color Management Software: Software such as Adobe Photoshop and Illustrator gives the designer the ability to pre-view colors to be printed by modifying the color schemes in the design or RGB to CMYK formats.

Preview Gamut Warnings: These are tools that indicate the out of the range of CMYK colors in RGB and this helps in the making of changes before the artwork can be finalized.

CMYK Right Away: This is to say that in case the final material will be a printed one, it may be better to get the work started in CMYK right away to enable closer representation of the color.

Pantone Matching: Pantone system is applied in colors that cannot be replicated accurately with CMYK and allows some possibilities to achieve accurate matching between the results of the digital and print.

Realizing the limits and capabilities of the respective models, designers will be able to construct visually atypical projects that could sustain their impact in both digital and print media. The ability to successfully bridge the gap between RGB and CMYK is a critical element of successful and professional design in the multi-platform age.

8. Innovations and Future Trends

8.1 Advances in Printing Technology

The technology of digital printing has led to the increased efficiency and quality in the traditional model of CMYK. Digital printing on a sheet of paper differs with the traditional offset printing in that with Digital printing an exact amount of ink can be controlled on the sheet and wastage is reduced improving color faithfulness.

Key Innovations:

Extended Color Gamut: New digital printers have more inks, like orange, green and violet, to extend the CMYK gamut which will bring richer and more vibrant colors.

Variable Data Printing (VDP): It enables the printing of a high quality customized content using CMYK optimization, where targeted marketing is done by personalizing the marketing campaign.

High-Resolution Printing: Newfound capabilities in the printhead design and ink composition yield a sharper image with more detail, so CMYK printing is now applicable to such specialist uses as art reproduction and high-quality packaging.

Digital printing continues to redefine what is possible with CMYK, enabling faster production times, cost efficiency, and unparalleled customization.

8.2 Sustainable Color Mixing

Due to the increasing concerns regarding the environment, industries are moving towards the more sustainable mode towards the color mixing and printing in a more sustainable pattern. Conventional inks and pigments usually involve using chemicals which are destructive to the eco system. These issues are being offset by eco-friendly materials and techniques innovation.Sustainable Solutions:

Eco-Friendly Pigments: Scientists are working on water based, biodegradable ink that have less focus on chemical wastes and toxicity levels.

Recycling and Reduction of wastes: The printing presses are modernized and this means that they are built in such a way that the wastes are recycled and any wastes as little as possible.

Green Printing Techniques: Waterless printing, energy-saving curing processes are a few methods, which are shrinking the environmental impact of print production.

Not only are these sustainable practices in line with the global environmental agenda, but their use also adds to brand credibility in companies that strive to employ solutions that are conducive to environmentally friendly practices.

8.3 Integration with AI and Digital Tools

Digital tools and artificial intelligence are disrupting the color mixing and designing processes offering precision and creativity at a scale never achieved before.

AI-Driven Optimization:

Predictive Color Matching: Artificial intelligence tools examine how the ink, materials and light interact improving that fact that the actual appearance of the color stays consistent between media.

Automated Adjustments: Artificial-intelligence driven tools can automatically adjust colors to optimize them to best print, limiting human error, and increasing time spent on other manual corrections.

Color Trend Analysis: The AI-based systems deal with consumer preferences and market trends and provide data to designers on the popular color configurations and palettes.

Enhanced Design Tools:

Virtual Prototyping: Prototyping on paper has improved with digital tools enabling the designer perceive how colors would look like under certain lighting condition and different materials to ensure that the vision is equivalent to the final output.

- Creative Tools Machine Learning: AI restrictions are even being redefined in creative software tools with the use of the technology to recommend color schemes, gradients, and harmonies conferring even more creative opportunities on platforms such as Adobe Photoshop and Illustrator.

Through the interaction of artificial intelligence with human imagination, both the subtractive color mixing and the design along with them will be more imaginative, effective, and evolutionary to the changing needs of the industries and consumers.

9. Conclusion

Subtractive color mixing is still one of the key principles of design, art and printing. Its scientificity and application enables the professional to generate lively and precise output in a variety of physical practitioners. With this knowledge of techniques, designers and artists are able to raise their work to another level and remain at the center of their field. May the art and science of subtractive color mixing make you motivated to create something that is precise and sustainable, and impactful.

About Us

How soon we can get a sample?

Usually,reference sample within 2 days. Customized sample need 5-7days.

Rigid Drawer Box

What are the wholesale pricing options for bulk orders?

We offer competitive wholesale prices for bulk orders. Please contact our sales team for more details

OEM Services

Do you offer eco-friendly and sustainable packaging options?

Yes! We provide environmentally friendly packaging solutions, including recyclable, biodegradable, and FSC-certified paper materials. Let us know if you’re looking for sustainable options.

What types of packaging products do you offer?

We specialize in a wide range of packaging solutions, including:

Custom labels and stickers

Paper bags and gift boxes

Beauty and cosmetic boxes

Food and beverage packaging

Pharmaceutical and healthcare packaging

Jewelry, electronics, and toy packaging

Luxury and high-end packaging solutions

If you have specific requirements, we can customize products to fit your needs.

About Printing Craftsmanship

How does UV printing work?

UV printing uses ultraviolet light to cure ink instantly, resulting in vibrant colors, water resistance, and high durability. It is commonly used for packaging, signage, and promotional items.

Start Your Packaging Journey Today

Discover Our Curated Collection of Bespoke Packaging Cases & Tailored System Solutions

© 2025 WINPACK PRINTING. All rights reserved

Wenhua Printing packaging

winpackprinting

Winpack Printing