The Master Guide to Tin Box Packaging for Your Products

Are you looking for a versatile, durable, customisable luxury product in a lightweight container that is ideal for storing food, cosmetics and other items? Metal tin boxes are a great option and have been popular for decades. So, if you're planning your next big packaging project and considering this premium option, you've come to the right place!

This guide will tell you everything you need to know about metal tins before embarking on your next packaging project.

- What are tin boxes?

- The pros and cons of tin packaging

- Tin packaging: Myths and legends

- So, is tin packaging right for your product?

- Popular tin shapes

- Tin styles, options and accessories

- Promotional/Merchandising

- Types of tin materials

- Printing on tin: Finishes on surfaces

- How are tin boxes made?

- What works with tin containers?

- Want to start your tin box project?

What are tin boxes?

Tin container packaging is made of metal and is highly durable. It can be customised in a variety of ways, including metallic reflections, varnishes, coatings, embossing, debossing, high-quality printing methods, and textures.

However, it is important to note that aluminium tin packaging is sometimes used as a synonym for tin containers and boxes, despite the two being very different. Here, we will focus on tin packaging.

The pros and cons of tin packaging

Although tin containers can enhance the presentation of your products to customers, they may not always be suitable for every product. Before we go further, let's look at the pros and cons of custom metal tin packaging. This guide will only cover the main points, but if you would like to read more about the pros and cons of using tin containers, you can do so here.

Advantages of Tin Containers

Using a tin box to package your products has many advantages. The key benefits are:

- Durability and strength: Tin packaging ensures that your products will not be damaged during storage, transportation or handling.

- Long shelf life: Tin containers prevent physical damage and offer adequate protection against light, moisture and oxygen, keeping products fresh and preserving their taste for significantly longer.

- Premium aesthetic appeal: Tin boxes stand out due to their unique metallic lustre and high level of customisation.

- Reusability and recyclability: Tin boxes made of tinplate or steel can be recycled and melted to produce new metal products. The quality features, such as magnetic lids or closures, complement the high-quality appearance, encouraging consumers to retain the container for other uses and extending the product's lifespan.

- Flexibility: As well as being highly customisable, the shape of the tin can also be adapted. Tin containers can be shaped into different sizes and shapes to suit different products and uses.

Cons of tin containers

As with any form of packaging, there will always be a list of cons for tin containers. The major drawbacks of this kind of packaging are:

- Price: Tin packaging is more expensive than plastic or cardboard. Moreover, unique container shapes created using custom moulds can increase prices considerably.

- Weight: Although tin is lightweight, it is heavier than most other packaging materials, which can also add to shipping costs.

- Rust and corrosion: Containers can rust or corrode if they are not properly coated or lined and come into contact with moisture or acidic products.

Tin packaging: Myths and legends

Although tin packaging has been widely adopted over the years, certain misconceptions about it discourage people from using it.

Tin containers are expensive

The most widespread myth is that tin containers are expensive. While it's true that tin packaging may be more expensive than other materials, it certainly won't break the bank! Its longevity and durability justify the investment, which brings us to our second misconception.

Tin packaging is not environmentally friendly

It is believed that tin packaging is not environmentally friendly. While this is partially correct in that high-tech manufacturing processes are required, the carbon footprint generated by tin is smaller than that of plastic. Moreover, tin can be completely recycled, leading to a circular economy, and is therefore far more environmentally friendly than one might think.

Tin boxes are prone to rust

Lastly, we will discuss the myth that tin is susceptible to rust. We mentioned rust and corrosion as a possibility in the disadvantages section. However, this is only applicable when the container is coated incorrectly. Tin is a pure metal and does not rust. Rust is the underlying metal of the tin. If a professional applies the coating properly, your container will not rust!

So, is tin packaging right for your product?

After considering the advantages, disadvantages and misconceptions, you may still be uncertain about using tin for your next packaging project. The easiest way to decide is to think about what you want from a package.

Do you want brand recognition and competitive differentiation? Would you like to make your product appear more valuable to customers? Do you need packaging that provides good protection and can accommodate the shape and size specifications of your product?

If you answered yes to the above questions, then tin containers are certainly an option you should consider. In that case, we shall proceed!

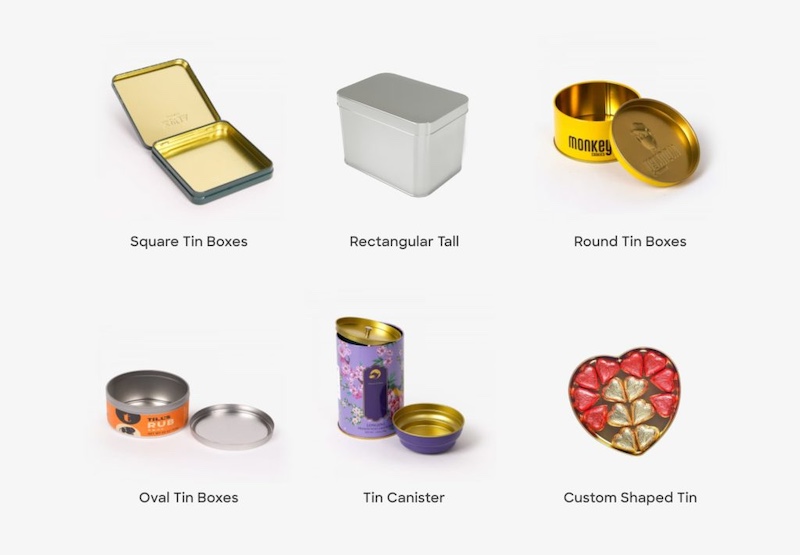

Popular tin shapes

As we mentioned, tins can be different sizes and shapes. Here, we will explore the many options available to you.

Rectangular & Square Tin Box

Rectangular and square tins are the most traditional. They are simple and easy to understand, and are therefore the standard for tin containers. They can also be stacked easily, resulting in easy storage and transportation.

Oval & Round Tin Containers

Oval and round containers are another staple of the tin industry. Although they are not as efficient for storage as square tins, they offer additional aesthetic appeal and a feeling of high-end luxury that more than compensates for this.

Custom-shaped tin canisters

If none of the above appeals to you, you can also use tin containers in any shape you can imagine! Possible shapes include suitcases, books, cylinders and hearts.

Tin styles, options and accessories

As well as deciding on the shape of your tin, there are numerous other stylistic choices you can make, such as adding an additional layer of protection to your product or enhancing the beauty of your package even further. We will consider all the possibilities when creating your tin.

Tin lid styles

The lid of your container is the first thing you can customise. Popular options include:

- Slipcovers: These are lids with hemmed or curled edges that fit tightly around your container without twisting up. They may also include a clear acrylic window to allow consumers to view the interior. Slipcovers are smooth and waterproof and can be used for ointments and cosmetics.

- Slide top/sliding lids: As the name implies, these can be easily opened or closed by sliding the lid in or out. Slide tops are perfect for keeping sweets and mints fresh.

- Hinged lid/hinge top tins: This type of lid is attached to the container at one end via a hinge and can be easily removed by lifting the lid. Hinged lids can also close firmly to prevent contamination and spillage, making them suitable for plant-based products such as tea leaves, tobacco or cannabis.

- Screw top tins/screw caps: Screw caps resemble slipcovers, except that you have to twist the lid to open or close them. They may also have acrylic windows, providing added security by ensuring the lid is tight. Ointments and cosmetics are also well suited to screw caps.

Interior decorations for your tin

As well as choosing the style of lid for your tin package, you can also select any accessories you would like to add to your tin container. These accessories may include:

- Foam inserts: These are used to give the inside of your container a high-quality look and feel, as well as an added layer of protection.

- Plastic tray inserts: These keep your products in place without adding weight, and they can be customised with different colours.

- Cushion pads: These food-safe, sustainable paper cushion pads preserve food products.

- Compartments: Add metal separators to divide your container into various compartments.

- Preservation & Safety: You can also opt for food-safe tin sealing tape.

- PVC Tin Sealing Tape: This adhesive tape is specifically designed to seal the lids of tin cans and prevent contamination of the contents.

- Tamper-resistant locks: These are locking mechanisms placed on the lid and body of the container to offer added resistance to unintentional opening or tampering.

Promotional/Merchandising

In addition to the abundance of other customisations you can make, there are also promotional and merchandising options.

- Window lids/see-through lids: As mentioned in the lid styles section, it is worth repeating that customers find it very attractive to be able to see the product inside.

- Additional features: Adding a handle to your tin enables customers to easily transport your product anywhere.

- Custom printed tin packaging labels: A custom-made label will give your tin an additional brand personality.

Types of tin materials

As mentioned in this guide, tin boxes must not be confused with aluminium; they are two distinct metals with different properties. However, it is important to note that tin containers are not solely made of tin. Here, we will deconstruct some of the common materials that these containers may contain.

- Tinplate/tin-plated steel: This material consists of a steel or iron core coated with a thin layer of tin. This coating helps to prevent rust and corrosion, as well as increasing the durability of the container. Tinplate has a smooth, shiny surface that can be printed on and decorated. Common uses for this material include food packaging, cosmetics and gifts.

- Frosted iron has a matte, slightly rough finish that distinguishes it from standard tinplate. It is aesthetically appealing, non-reflective and highly durable, providing customers with a high-quality look and feel. Frosted iron is best suited to high-end products that need to look classy.

- Pure tin: As the name suggests, pure tin is not commonly used in the manufacture of tin containers because it is more expensive and weaker than the alternatives. Nevertheless, pure tin is highly corrosion-resistant, non-toxic and ideal for high-end, speciality or limited-edition products.

Printing on tin: Finishes on surfaces

You can add custom designs or your brand logo to a tin container by printing it, creating a unique packaging experience that will delight your customers. As with all other customisations in this guide, you have a wide range of options for the surface finish of your tin box.

- Lithography (offset printing): This printing method is used for food packaging, promotional tins and gift boxes. The process involves copying an image from a metal plate onto a rubber blanket and then onto your tin. Lithography provides high-quality, detailed images at a low cost for large-volume production.

- Screen printing: Also known as silk-screen printing. It is mostly used for limited edition designs and custom logos. This printing method uses a flexible range of inks on the tin via a mesh screen, and bold colours and solid areas of colour can be achieved.

- Digital printing: This is ideal for short runs or individualised designs. This printing method is cost-effective for smaller batches, and turnaround time is quick since images are printed on a tin using digital files.

- Embossing and debossing: These are surface finish methods that give your tin a 3D appearance, either raised (emboss) or recessed (deboss). It is ideal for designing high-quality packaging for luxury products or improving your branding. Embossing and debossing also provide a tactile quality to your tin and add visual interest, and can be applied to other printing methods.

- Flexographic printing: Flexible relief plates are used to print on a surface, enabling the production of continuous patterns and simple designs in large quantities. This type of printing is best suited to mass production, labels and simple graphics.

- Pad printing: In this printing technique, a silicone pad is used to transfer ink onto a tin surface. This makes it suitable for irregular shapes, complex logo designs and other textured surfaces.

- UV printing: UV light is used to cure the ink when it is printed onto the tin. This enables rapid drying, great durability, and bright colours, which can be used for detailed pictures and designs.

- Hot stamping: Heat and foil are used to stamp metallic patterns onto tins, offering a luxurious finish for high-end products, eye-catching branding and ornamental features.

How are tin boxes made?

Now that you have seen all the great choices available to you, it is time to get down to the nitty-gritty and create your container!

At this stage, brands usually turn to manufacturers of tin packaging, as they are the professionals who can offer the best solutions for your project. Nevertheless, it is always helpful to understand the production process to know what you are buying.

Step 1: Selecting your tinplate sheet

The first step is to select your tinplate sheet. Tinplate comes in different thicknesses, which affect the longevity and print quality. Once you have chosen your tinplate, the manufacturer will cut the sheets with cutting machines to prepare them for the next steps.

Step 2: Printing and coating

The next step is printing and coating, which involves applying your designs and protective coatings to the cut pieces of tinplate.

Step 3: Shaping and complete assembly

After you have applied your designs to the material, the sheets are stamped and shaped using stamping and forming machines. It is in these machines that the material is moulded into the various components of your tin box: the lid, body, and base.

Once all the components have been developed, the final structure is created by assembling the container using mechanical interlocking or welding. Seaming is then done on the structure to close the edges, ensuring a tight fit, structural integrity and that it does not leak.

Step 4: Quality Control

Finally, once you have finished your tin, it will undergo a quality control check to ensure that it meets the required standards and is free from defects.

What works with tin containers?

Although tin containers can be used for almost anything, some products are particularly well-suited to them.

- Food & Beverage: Tin is widely used for food packaging and is arguably the most widespread industry for such containers. Tin containers are popular for items such as biscuits and coffee.

- Cosmetics & Personal Care: Another industry that uses tin is the cosmetics and personal care industry. The small size and portability of tin cosmetic packaging makes it ideal for use on the go and during travel.

- Gifts and Promotional Items: Tin containers are an excellent way to present gifts or promotional products thanks to their luxurious appearance, unique shapes, and various printing possibilities.

Want to start your tin box project?

The above products are proven when it comes to tin packaging; however, this does not imply that other products cannot work as well! The most enjoyable thing about custom packaging is that you can be as creative as you like and experiment, so take inspiration from our tin packaging catalogue!

Alternatively, if you have already made your decision and are looking for a partner to help you start your custom tin can packaging journey, Winpack Printing can assist you. Together, we can create something special.

OEM Services

What types of packaging products do you offer?

We specialize in a wide range of packaging solutions, including:

Custom labels and stickers

Paper bags and gift boxes

Beauty and cosmetic boxes

Food and beverage packaging

Pharmaceutical and healthcare packaging

Jewelry, electronics, and toy packaging

Luxury and high-end packaging solutions

If you have specific requirements, we can customize products to fit your needs.

About Printing Craftsmanship

What is screen printing used for?

Screen printing is ideal for printing on a variety of surfaces, including:

Fabric (t-shirts, tote bags)

Plastic (bottles, packaging)

Paper (posters, packaging)

Metal and glass (signs, promotional products)

What are the different types of printing techniques?

There are various printing techniques used for different purposes, including:

Offset Printing – Ideal for high-volume commercial printing, offering sharp and high-quality images.

Digital Printing – Suitable for short-run printing with fast turnaround times.

Screen Printing – Used for printing on textiles, plastics, and other materials with thick ink layers.

Hot Stamping – Adds metallic or pigmented foil using heat and pressure for a luxurious look.

Embossing & Debossing – Creates raised or recessed designs for a textured effect.

UV Printing – Uses ultraviolet light to instantly dry ink, offering vibrant colors and enhanced durability.

Rigid Magetic Boxes

Can I print on the inside of the box?

Yes, you can print any effect you want on the inside.

Special Shape Boxes

What are the wholesale pricing options for bulk orders?

We offer competitive wholesale prices for bulk orders. Please contact our sales team for more details

Start Your Packaging Journey Today

Discover Our Curated Collection of Bespoke Packaging Cases & Tailored System Solutions

© 2025 WINPACK PRINTING. All rights reserved

Wenhua Printing packaging

winpackprinting

Winpack Printing