Void Filler in Packaging

When packing your product for transportation, it is important to consider not only the packaging itself. It is also important to consider what you put in the box to provide additional security for your product and make it more appealing. This is where filling comes in!

1. What is a void filler?

It can also be referred to as void fill, package stuffing, shipping padding or simply filler. However, they all fulfil one major role: securing a product, regardless of their different names. Void fill refers to anything placed in a shipping box to cushion the product against movement, rough handling and potential drops by filling the empty space in the package.

2. Advantages of void fill packaging

It is not only fragile items that can be packed in void-filled boxes. Filler has numerous advantages when it comes to packaging any product. Heavy products, especially those with sharp edges, can easily cut or tear exterior packaging, but suitable fillers can prevent this.

With the expansion of the e-commerce market, box filler is not just about protection; it can also be used for aesthetic purposes to enhance your brand and make it stand out from the competition. In this saturated e-commerce market, companies should use fillers as one of the elements of their branding and unboxing experience strategy. With protection and aesthetics in mind, we will now look at some typical box-filling materials you can use to package your product, and explain why you should or shouldn't use them.

3. Popular types of packaging filler material

--Paper fillers

Paper is one of the cheapest packing filler alternatives since any type of newspaper or crinkled paper can be used to provide extra protection at minimal additional expense. Paper is also an environmentally friendly void fill packaging option for companies looking to reduce their environmental impact. With this in mind, we will now look at some popular paper options.

Packing paper is thin kraft paper that can be folded around a product or scrunched up to provide additional cushioning within a box. Packaging paper is understated, giving a touch of elegance to products such as clothes or books. Packing paper creates anticipation for consumers about what is under the wrapping, and is environmentally friendly for brands that want to utilise recycled or recyclable materials.

In other cases, more durable products, such as shoes or clothing, can be packaged with custom tissue paper. Although it provides less protection than packing paper, it gives your packaging a more upscale, luxury feel. Custom tissue paper is also a good option since you can brand it to make your packaging stand out from that of your competitors.

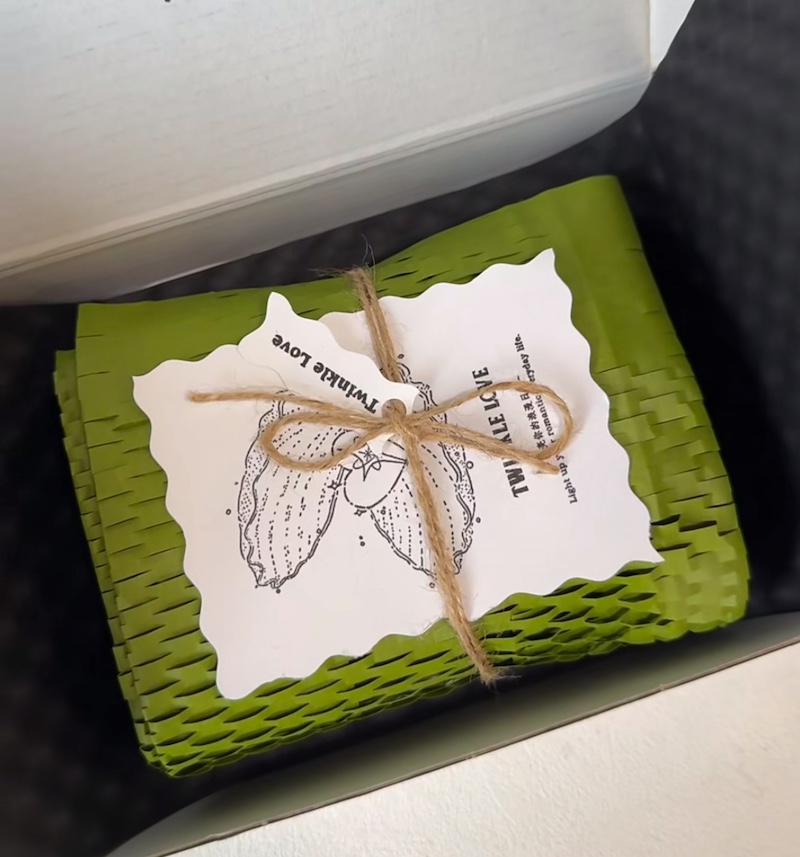

Lastly, if you are looking for something that has gained popularity in recent years due to its sustainability, consider honeycomb paper. Composed of biodegradable and recyclable silk paper, it is lightweight, meaning that it does not require as much material to occupy the same space as traditional paper filling. Honeycomb paper is ideal for delicate products such as glass.

--Cardboard fillers

Cardboard partition dividers separate and stabilise your goods in a box. They are usually made of cardboard, but lightweight wood is also an option. Partitions are widely used in larger boxes containing multiple cases of the same product, such as bottles, cosmetics or jars. They prevent goods from colliding during transportation and are ideal for larger, heavier items. While dividers are not particularly aesthetic, they are highly effective at safeguarding delicate items.

However, if you want to add a wow factor to the interior of your box, internal inserts are the answer. These are cut pieces of cardboard that are intricately designed to present your product well to the consumer when the box is opened. They are inserted to fill the gap between your product and the packaging, and are ideal for products with more than one item or for luxury or fragile products.

--Wood excelsior

Another environmentally friendly void filler alternative to paper and cardboard is wood excelsior. Wood excelsior is shaved, curly wood that usually smells nice when consumers open a package. It creates a special unboxing experience that appeals to consumers' sense of smell, making products feel more rustic and luxurious. However, note that the odour of wood excelsior may transfer to less sturdy objects, such as clothing, and it may therefore not be appropriate for such products.

--Bio foam fillers

Packing peanuts and bio foam are made of polystyrene foam and are widely used today. Conventional packing peanuts are very detrimental to the environment, but a new, biodegradable version made from plant-based materials has now been introduced to the market, albeit at a higher cost.

Packing peanuts are a great option for wrapping delicate objects of unusual shapes and sizes in a short amount of time. However, they cannot be customised, which puts them at a disadvantage in the current market.

--Packaging air bags

Another inexpensive and quick method of protecting products during transportation is air bags or air pillows. However, there is a major disadvantage to this type of filler. Although air pillows are effective at protecting products, they consist of plastic bags filled with air, which poses a significant environmental problem. Air pillows are available in different sizes, but they are not usually applicable to small objects.

--Bubble wrap

Similar to air pillows and packing peanuts, bubble wrap is a fast, cheap and efficient method of wrapping your products. As with the other quick methods of securing your product, bubble wrap is not customisable. It is made of single-use plastic, which is again an ecologically harmful alternative.

4. What filler should I use for my packaging?

There is no right or wrong answer to this question. There are numerous factors unique to your packaging situation that you need to take into account to decide which filler is most suitable for your product. These include your sustainability goals, branding objectives, required level of protection and, of course, budget.

Fortunately, Winpack Printing has compiled a comprehensive guide to help you choose the right filler insert for your needs. However, if you need packaging services, call one of Winpack Printing's product specialists today! We will be glad to help with any of your packaging needs!

Folding Boxes

How long does it usually take from design confirmation to delivery?

Answer: The delivery time of folding boxes is usually 15-25 days, depending on the production of the order

About Printing Craftsmanship

What is embossing, and how is it different from debossing?

Embossing is a technique that creates a raised impression on a material, while debossing presses the design inward, creating a recessed effect. Both techniques add texture and sophistication to printed materials.

What factors should I consider when choosing a printing technique?

Material: Some methods work better on specific surfaces (e.g., screen printing for fabric, offset for paper).

Budget: Offset is cost-effective for large runs, while digital printing is better for short runs.

Aesthetic & Finish: If you need metallic effects, choose hot stamping; for texture, consider embossing.

Durability: UV printing and screen printing offer long-lasting prints resistant to fading.

About Us

How long does shipping take?

Air freight options range from 7-21 days, while ocean freight options range from 26-71 days. If you need some units expedited earlier, consider splitting your shipment between air and ocean!

Rigid Drawer Box

Can I get a sample before placing a formal order?

Yes, we provide samples to our customers. Please contact our sales team to inquire about sample availability and pricing.

Start Your Packaging Journey Today

Discover Our Curated Collection of Bespoke Packaging Cases & Tailored System Solutions

© 2025 WINPACK PRINTING. All rights reserved

Wenhua Printing packaging

winpackprinting

Winpack Printing