What is Spot UV Printing?

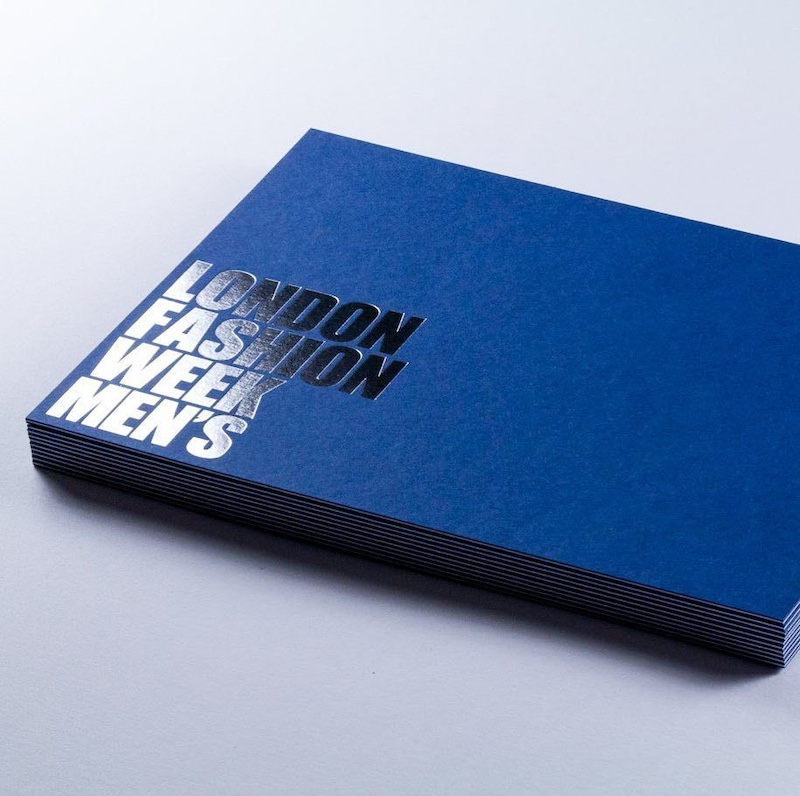

Spot UV printing is a well-known coating process that has become very popular in recent years thanks to its ability to give printed materials a glossy, raised finish.

It involves applying a clear, shiny UV varnish to certain sections of a printed piece to create a contrast between glossy and matte areas.

Spot UV is typically used for printing business cards, postcards, and other marketing materials to make them more appealing and eye-catching.

In this way, spot UV printing can be an effective means of bringing a sense of luxury and professionalism to your prints.

1. What is Spot UV?

It is one of many speciality printing methods used to create impactful packaging and differentiate brands/products.

Similar to lamination, it enhances the perceived quality of printed objects. This method can be used to enhance the main features of your packaging, such as:

- Logos

- Slogans

- Artwork designs

- Images

Please note that spot UV printing is a coating process, not a printing process.

UV printing involves the application of ultraviolet or UV light to white card stock or colour-printed paper products.

The UV light cures the varnish applied to the printed material, giving any design element a glossy finish.

This coating is applied to certain areas of the printed product to fix the colour, provide a beautiful finish, and protect the surface from moisture and wear and tear.

Spot UV printing can also be used to create a variety of textures on a printed surface, producing a dramatic, eye-catching effect.

2. Why use spot UV printing?

Spot UV printing and packaging offers several advantages that can enhance the quality and appearance of a product.

Firstly, it can significantly enhance the visual appeal of printed materials, making them more attractive and eye-catching. This can help to capture consumers' attention and make a product stand out on shop shelves.

It is also possible to use Spot UV printing to achieve a luxurious and professional appearance, which could enhance a brand's image and make it appear high-end.

The second advantage of applying Spot UV is that it protects printed material from wear and tear, thereby prolonging the product's lifespan.

Lastly, Spot UV provides consumers with an interactive experience that can foster brand loyalty.

3. The benefits of Spot UV

General impression: The added feature of Spot UV provides a remarkable and unquestionable experience for viewers who have never seen it before. It creates a visual impression that regular coated printing cannot achieve.

It is environmentally friendly as UV coatings contain no solvents and do not produce volatile organic compounds (VOCs) during the curing process.

Fast and efficient: UV coatings dry very quickly, which contributes to fast lead times. The method's accuracy is impressive given its speed.

Protective layer: Spot finish also provides good protection against moisture, as the colour of the printed item is sealed.

4. Spot UV coating applications

UV coating has many uses;

- Business cards

- Invitation cards

- Brochures

- Flyers

- Postcards

- Card stocks

- Packaging boxes

A number of finishes are possible, including light and high-gloss UV coatings to produce elegant matte, satin and neutral finishes.

This flexible method can be used with heavy and thinner paper stocks, but not with very fine and thin paper.

--Spot UV on matte lamination

Spot UV on matte lamination creates a striking effect on packaging, brochures and other printed materials.

Spot UV and soft matte laminate are glossy, which emphasises the message or graphic because the colours become darker.

Apple uses this method to showcase their minimalist and sleek product designs.

The iPhone packaging features a matte, laminated, spot UV-printed, glossy Apple logo against a matte background. This subtle yet eye-catching design sets the tone for the overall Apple user experience.

If you want your brand logo and images to be visible from a distance and have a high-end feel, add spot UV on matte laminate to your list.

--Applying Spot UV to a matte varnish

The packaging has a smooth, non-glossy surface thanks to the matte varnish. The combination of Spot UV and matte varnish is particularly popular for luxury packaging, especially for jewellery and cosmetics.

Take Glossier, for example:

Spot UV printing is used in Glossier's packaging design to create a minimalist and elegant look that aligns with the brand's overall image.

Not only does it look great, it also provides a protective coating for the packaging, preventing damage over time.

Glossier's use of Spot UV is an excellent example of how this method can improve a brand's image and give its products a high-end feel.

The mixture makes certain parts of the printed surface more vibrant, creating a luxurious contrasting appearance.

--Spot UV is applied to a soft-touch matte finish.

The packaging has a soft-touch matte finish that enhances its tactile qualities.

Another way to achieve a sophisticated appearance and smooth touch is to combine spot UV and a soft-touch matte finish. Silk Spot UV combines soft-touch and Spot UV.

5. The Spot UV process

The client provides a mask file containing instructions on where to apply the UV coating. A silk screen is then used to apply the UV coating to the chosen areas.

Mask files cannot have gradients or blurred edges, and all the artwork must be black or white with clean, sharp edges.

Spot UV should only be applied to a small area of the printed object, such as the message or artwork. Excess on the surface area may appear cluttered and aesthetically displeasing.

Considerations for using Spot UV in packaging

When using Spot UV for packaging, a number of important factors must be considered to achieve the best results. These factors include:

The type of paper or material to be printed. This is because the type of material can significantly influence the end result of the Spot UV process.

Certain materials, such as uncoated paper and some plastics, may not be compatible with this method, or may require special preparation, so care should be taken when choosing materials.

The design of the printed material: The design is also a crucial consideration. Spot UV can be used to emphasise specific parts of an artwork, so consider which parts of the design would best be emphasised using this technique and how it would be integrated into the overall design.

Spot UV printing is best suited to highlighting logos or focal points, as demonstrated by the examples.

The intended effect and outcome: When it comes to Spot UV, the intended effect and outcome should be taken into consideration.

For example, a gloss finish can make an item look high-end, whereas a matte finish can make it look more subtle. Consider what your project is intended to accomplish and the impact that Spot UV would have on the end product.

Budget factors: Spot UV may incur additional costs in the printing and packing processes, so the budget should be considered when deciding whether to use this method.

Consider the potential benefits and whether the application of Spot UV would be beneficial to the project.

Once these factors have been considered, you can make an informed decision about using Spot UV in printing and packaging to guarantee the best possible outcome for your project.

6. In conclusion...

Spot UV is a flexible coating method that adds an attractive and distinctive touch to printed materials such as packaging, brochures, and business cards.

It has numerous advantages:

- Increasing the beauty of printed material.

- Developing a high-end, business-like appearance.

- Providing wear and tear insurance.

- Providing consumers with a tactile experience.

Spot UV can be used on many types of material, including matte lamination, matte varnish and soft-touch matte finishes.

Adding Spot UV to a branding strategy can generally help to raise a brand's image and provide a luxurious experience of its products, as demonstrated by successful brands such as Glossier and Apple.

Be innovative and create an unparalleled unboxing experience!

Rigid Magetic Boxes

Can I order a sample of my packaging box?

Yes, we strongly recommend that you do so, we provide a variety of sample types to meet different usage situations and help you guarantee the best results!

About Printing Craftsmanship

What are the advantages of embossing?

Enhances the visual and tactile appeal of printed products.

Creates a premium and professional look.

Improves brand recognition with distinct textures.

Increases durability as the embossed design remains intact over time.

What are the different types of printing techniques?

There are various printing techniques used for different purposes, including:

Offset Printing – Ideal for high-volume commercial printing, offering sharp and high-quality images.

Digital Printing – Suitable for short-run printing with fast turnaround times.

Screen Printing – Used for printing on textiles, plastics, and other materials with thick ink layers.

Hot Stamping – Adds metallic or pigmented foil using heat and pressure for a luxurious look.

Embossing & Debossing – Creates raised or recessed designs for a textured effect.

UV Printing – Uses ultraviolet light to instantly dry ink, offering vibrant colors and enhanced durability.

OEM Services

How do I get a quote for my OEM order?

To receive a custom quote, simply contact us with your packaging requirements, including:

Product type and dimensions

Material preferences

Design specifications

Order quantity

Any special requests

Our team will assess your needs and provide a competitive quote tailored to your project.

About Us

How long does shipping take?

Air freight options range from 7-21 days, while ocean freight options range from 26-71 days. If you need some units expedited earlier, consider splitting your shipment between air and ocean!

Start Your Packaging Journey Today

Discover Our Curated Collection of Bespoke Packaging Cases & Tailored System Solutions

© 2025 WINPACK PRINTING. All rights reserved

Wenhua Printing packaging

winpackprinting

Winpack Printing